Modified attapulgite flue gas desulfurization agent and preparation and application thereof

A technology of attapulgite and desulfurizer, applied in other chemical processes, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of poor mechanical strength, large heat loss, high cost, etc., and achieve adsorption capacity and selectivity Improvement, reduction of wear consumption, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The modified attapulgite flue gas desulfurizer in this embodiment is attapulgite activated by heat treatment.

[0035] The preparation method of the modified attapulgite flue gas desulfurizer in this embodiment is carried out as follows:

[0036] a. The attapulgite clay is extruded by pair of rollers, and then dried and pulverized to obtain a powder with a particle size of 200 mesh;

[0037] b. Add distilled water to the attapulgite powder, stir at a high speed to form a suspension, and then centrifuge and dry to obtain an attapulgite sample; wherein the mass volume ratio of attapulgite to distilled water is 1g: 4mL;

[0038] c, the attapulgite sample is crushed and screened, and the selected particle size is 20-40 mesh as a spare;

[0039] d. Put 3 g of the spare product into a fixed-bed reactor, raise the temperature to 50° C. under nitrogen atmosphere, and perform constant temperature treatment at 50° C. for 2 hours to obtain a desulfurizer.

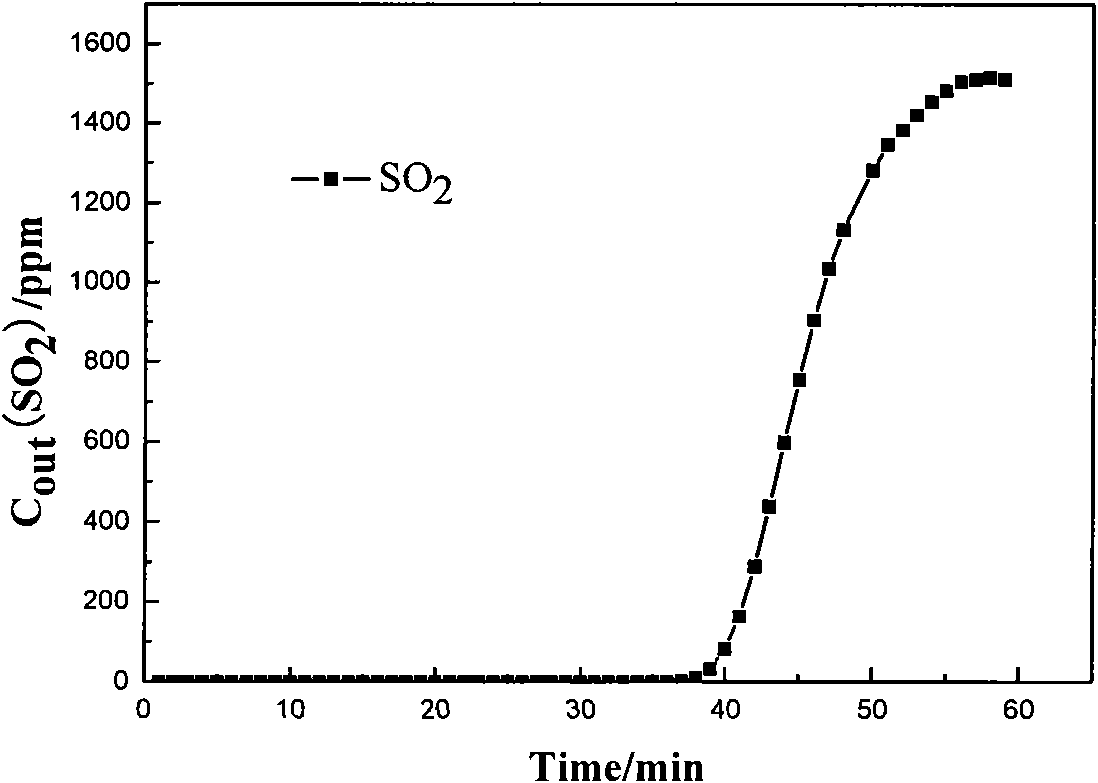

[0040] The applicatio...

Embodiment 2

[0043] The modified attapulgite flue gas desulfurizer in this embodiment is attapulgite activated by heat treatment.

[0044] The preparation method of the modified attapulgite flue gas desulfurizer in this embodiment is carried out as follows:

[0045] a. The attapulgite clay is extruded by pair of rollers, and then dried and pulverized to obtain a powder with a particle size of 200 mesh;

[0046] b. Add distilled water to the attapulgite powder, stir at a high speed to form a suspension, then centrifuge and dry to obtain an attapulgite sample; wherein the mass volume ratio of attapulgite to distilled water is 1g: 8mL;

[0047] c, the attapulgite sample is crushed and screened, and the selected particle size is 20-40 mesh as a spare;

[0048] d. Put 3 g of the spare product into a fixed-bed reactor, raise the temperature to 150° C. under nitrogen atmosphere, and perform constant temperature treatment at 150° C. for 2 hours to obtain a desulfurizer.

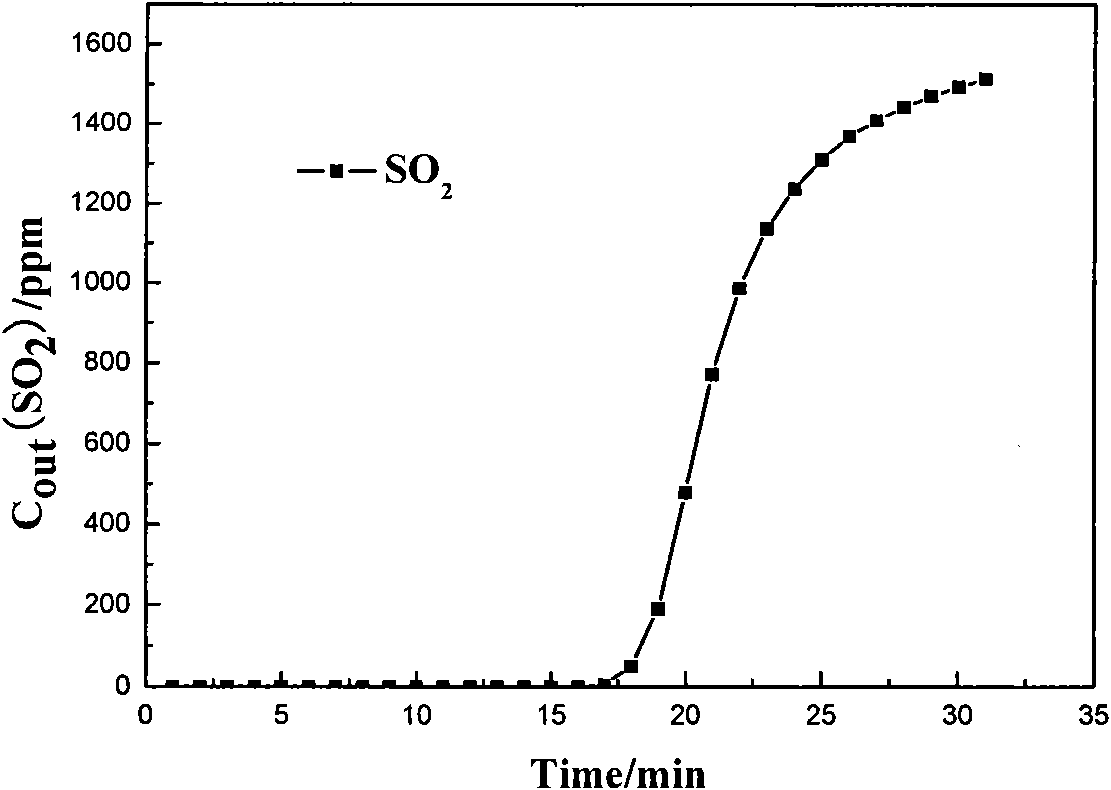

[0049] The application ...

Embodiment 3

[0052] The modified attapulgite flue gas desulfurizer in this embodiment is attapulgite activated by heat treatment.

[0053] The preparation method of the modified attapulgite flue gas desulfurizer in this embodiment is carried out as follows:

[0054] a. The attapulgite clay is extruded by pair of rollers, and then dried and pulverized to obtain a powder with a particle size of 200 mesh;

[0055] b. Add distilled water to the attapulgite powder, stir at a high speed to form a suspension, then centrifuge and dry to obtain an attapulgite sample; wherein the mass volume ratio of attapulgite to distilled water is 1g: 5mL;

[0056] c, the attapulgite sample is crushed and screened, and the selected particle size is 20-40 mesh as a spare;

[0057] d. Put 3 g of the spare product into a fixed-bed reactor, raise the temperature to 400° C. under nitrogen atmosphere, and perform constant temperature treatment at 400° C. for 2 hours to obtain a desulfurizer.

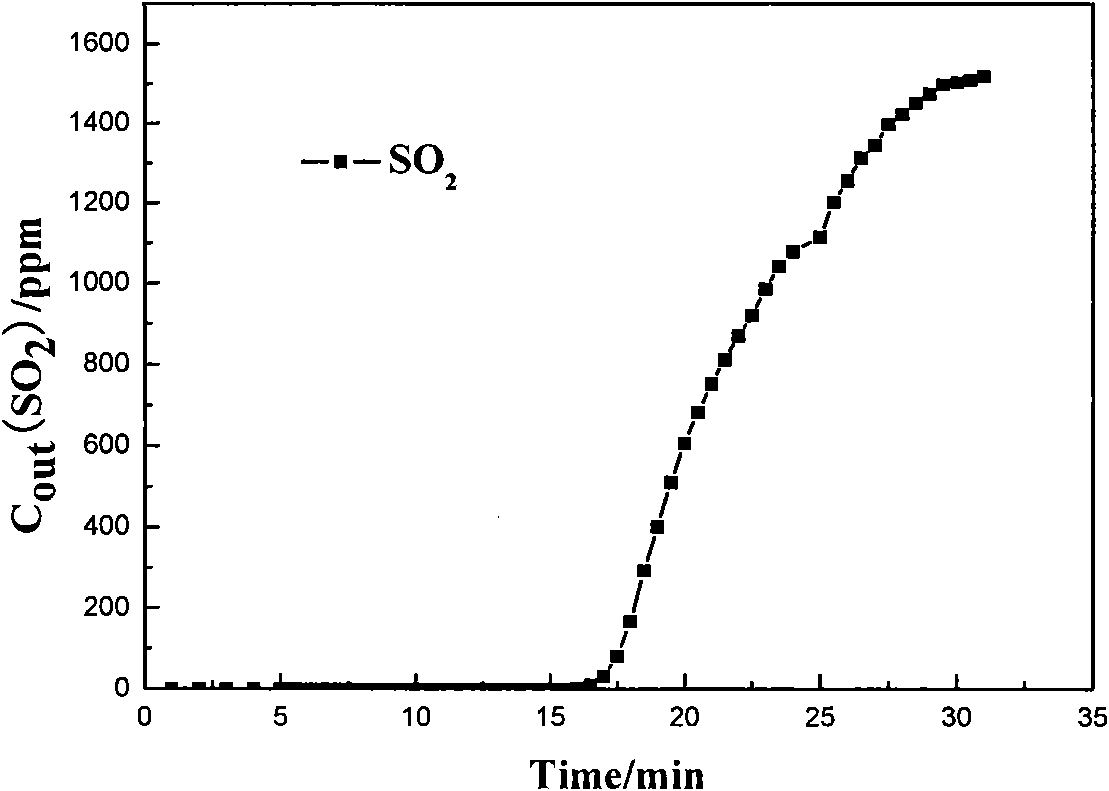

[0058] The application ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com