Method for controlling sand content of water body of blast furnace INBA circulating system and flow-limiting device thereof

A technology of circulation system and current limiting device, which is applied in the field of blast furnace smelting slag making process, can solve the problems of sand blockage in the relevant nodes of the circulation system, rapid wear of pipeline flow components, and lack of adjustment and control means, so as to reduce the overall cost of blast furnace smelting. cost, eliminate furnace sand discharge, and reduce the effect of output power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

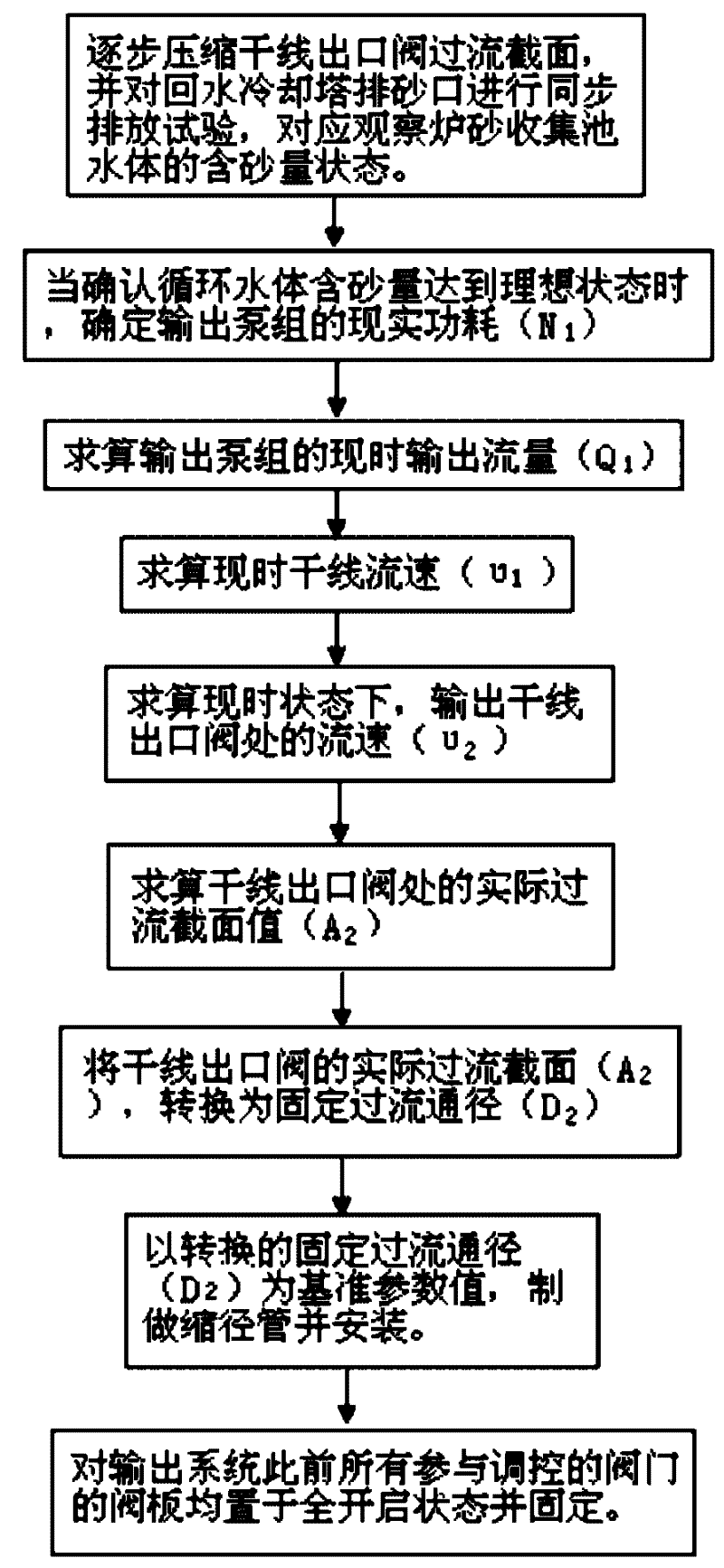

Method used

Image

Examples

specific Embodiment

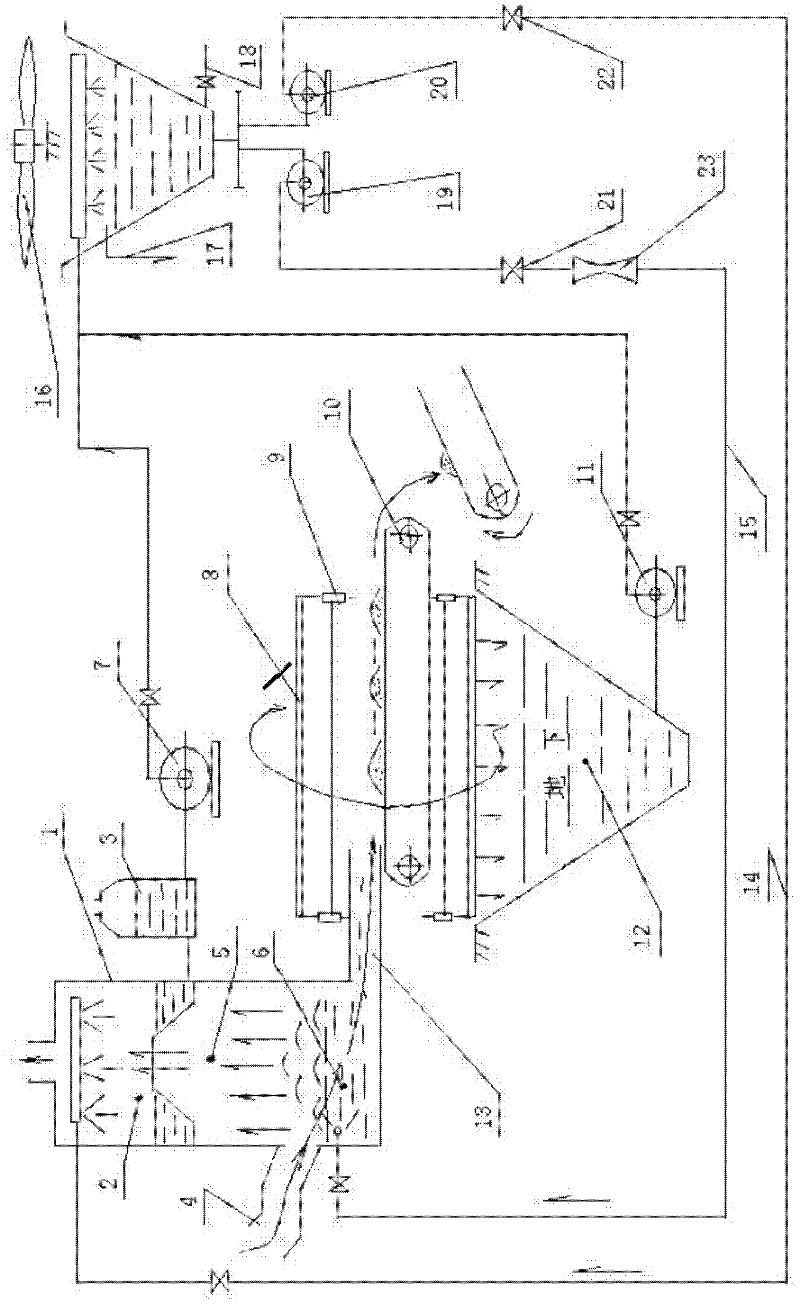

[0091] The new INBA water station of No. 6 blast furnace in our factory was put into operation in August 2008 after expansion and reconstruction. The water station provides production circulating water for 1# and 2# drum slag making systems of No. 6 blast furnace respectively. The overall setting is two sets of independent circulation systems, and the single system circulation output capacity of the granulation trunk line is 2500m 3 / h, the total output of double trunk line circulation is 5000m 3 / h.

[0092] The water station supplies water to two independent granulation slag making systems of the blast furnace through 2 output main pipes with a diameter of D600 (the operation is in reverse mode before expansion). For the blast furnace, the maximum return water capacity of each set of granulation slagging system is 3000m 3 / h (open underground pumping station, all incoming water in the foundation pit is sent back to the INBA cooling tower by the circulating pump through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com