Assembled steel bar truss floor support plate

A technology for steel trusses and floor slabs, which is applied to floors, structural elements, building components, etc., can solve the problems of dislocation of seams, inconvenient installation and disassembly, etc., achieve less dislocation of seams, facilitate workers to operate, and not easily Assembly chaos effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

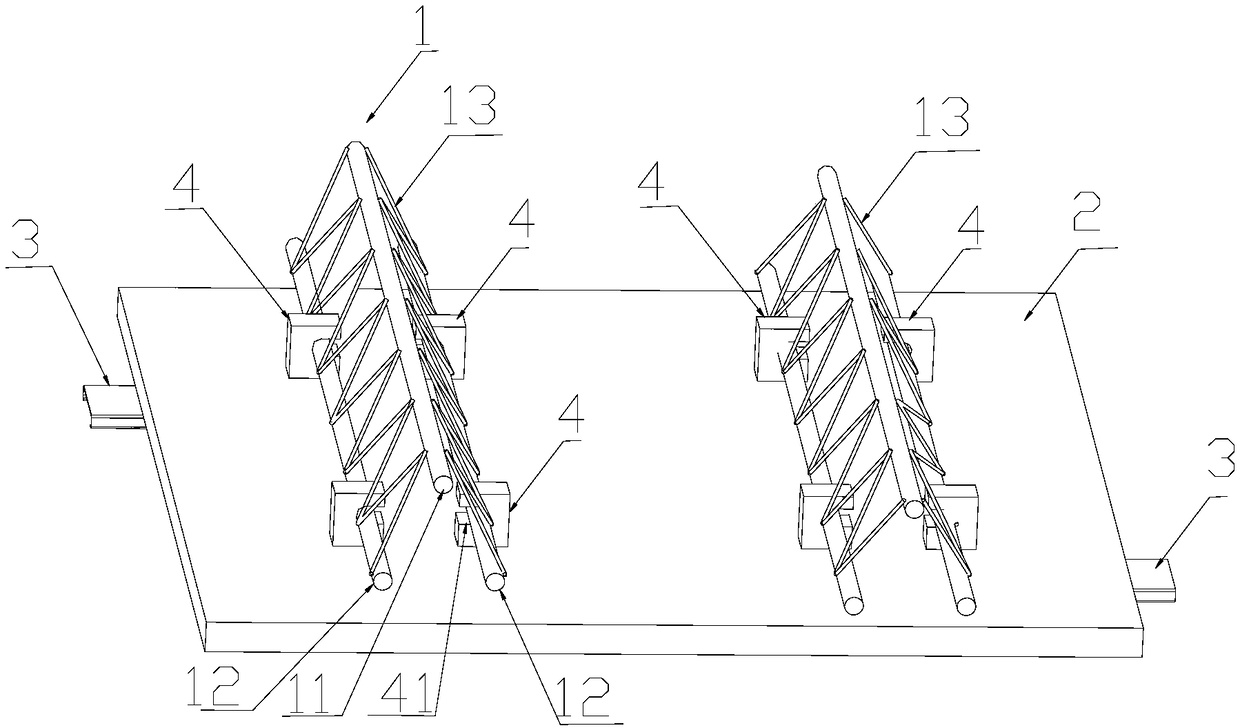

[0029] like Figure 1-3 As shown, a prefabricated steel truss floor deck comprises a steel truss 1 , a connecting piece 4 , a floor deck 2 and a supporting piece 3 . The steel bar truss 1 includes an upper chord steel bar 11 and two lower chord steel bars 12 , and the two lower chord steel bars 12 are respectively welded and connected to the upper chord steel bar 11 through the web bar steel bar 13 . The two lower chord reinforcing bars 12 are connected with connecting pieces 4 relative to each other. The connecting piece 4 includes a slot 41 penetrating the connecting piece 4 with a side opening, and the lower end of the connecting piece 4 is provided with a threaded hole. The connecting pieces 4 are clamped on the two lower chord steel bars 12 in pairs, and each pair of connecting pieces 4 is longitudinally arranged on the steel bar truss 1 . The floor deck 2 is connected with a support member 3 on the side away from the steel truss 1, and the support members 3 are distrib...

Embodiment 2

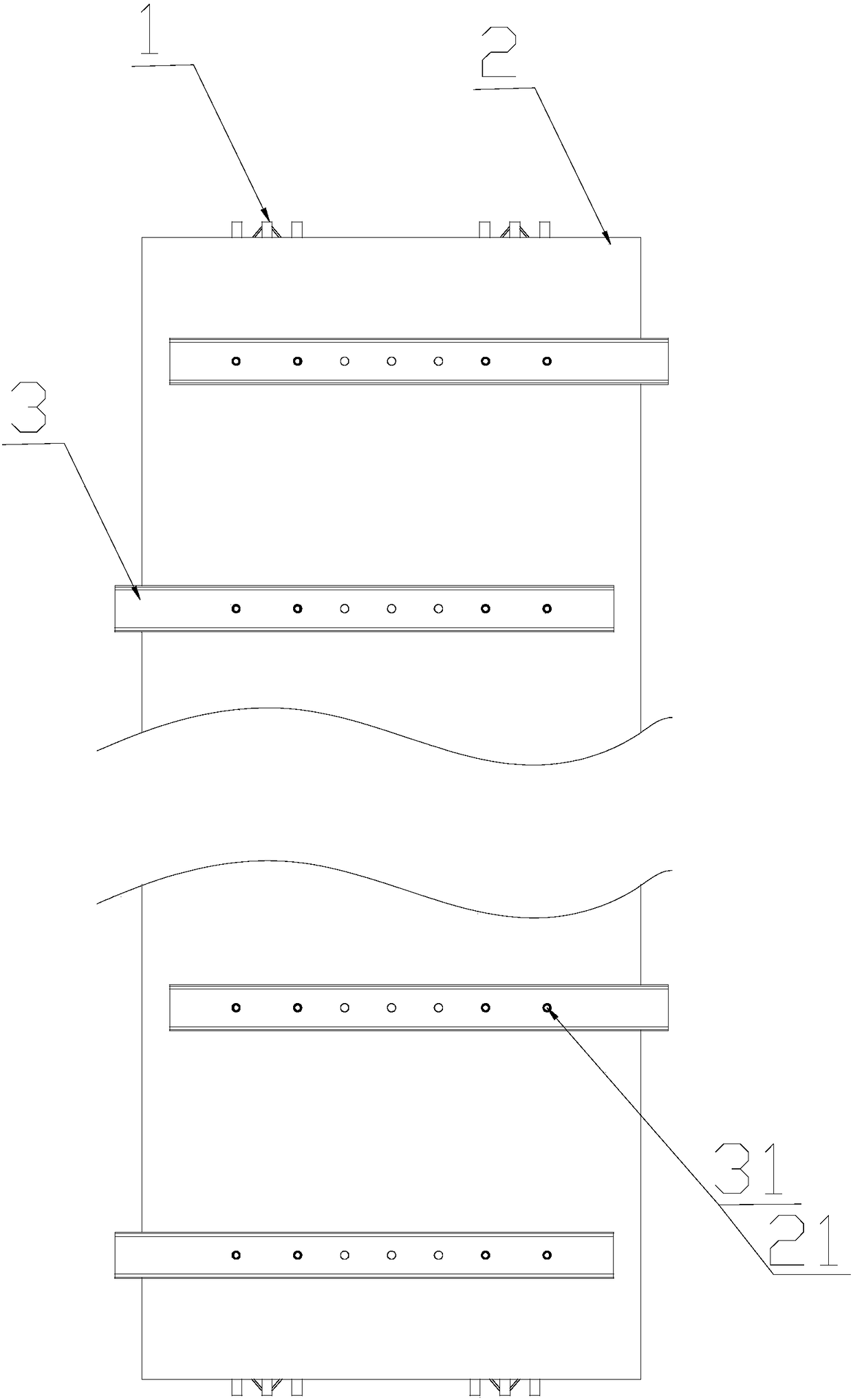

[0033] like Figure 4 As shown, the difference between this embodiment and the first embodiment is that every two supporting members 3 alternately protrude from the left and right sides of the floor deck 2. Of course, the supporting members 3 can also be staggered and protruding from the floor deck every two. 2 left and right sides.

Embodiment 3

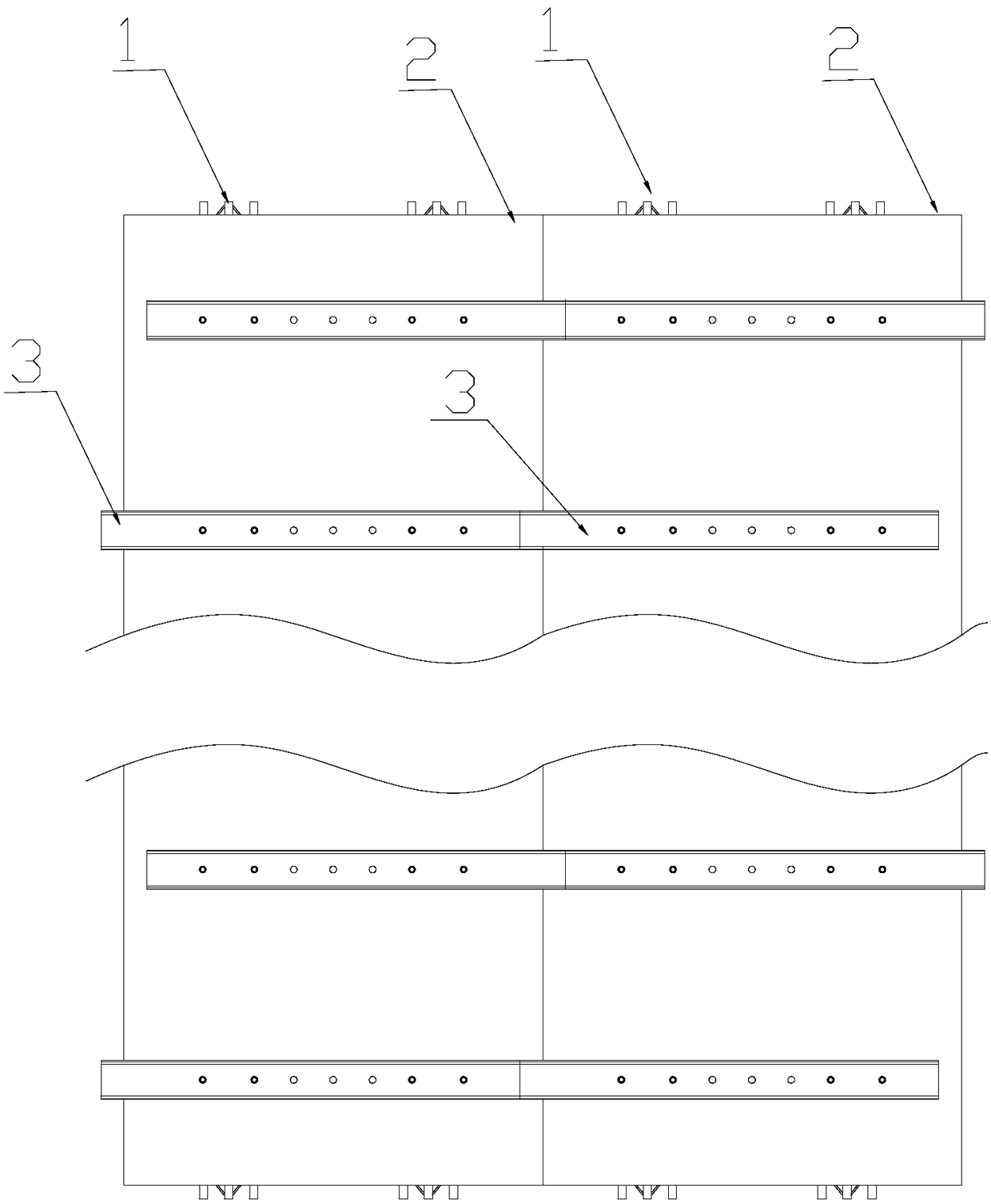

[0035] like Figure 5 As shown, the difference between this embodiment and the first embodiment is that the length of the support member 3 is greater than the width of the floor deck 2 , and the two ends of the support member 3 protrude from the left and right sides of the floor deck 2 . Therefore, the supports 3 of the adjacent prefabricated steel truss floor decks are dislocated and distributed. When splicing, both ends of the supports 3 support the adjacent floor decks 2 to reduce the dislocation of the splicing joints. Of course, if Image 6As shown, when the floor deck 3 is wider, the middle part of the support member 3 can also be disconnected to form a pair of first support parts 32 and second support parts extending from the left and right ends of the floor deck 2 33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com