Vortex spinning machine

A spinning machine, flow-feeding technology, applied in the direction of spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the wear of rubber roller and apron, the difference in drafting speed and spinnability Long-distance, short service life and other problems, to achieve the effect of increasing spinning speed, saving roving process and reducing wear and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

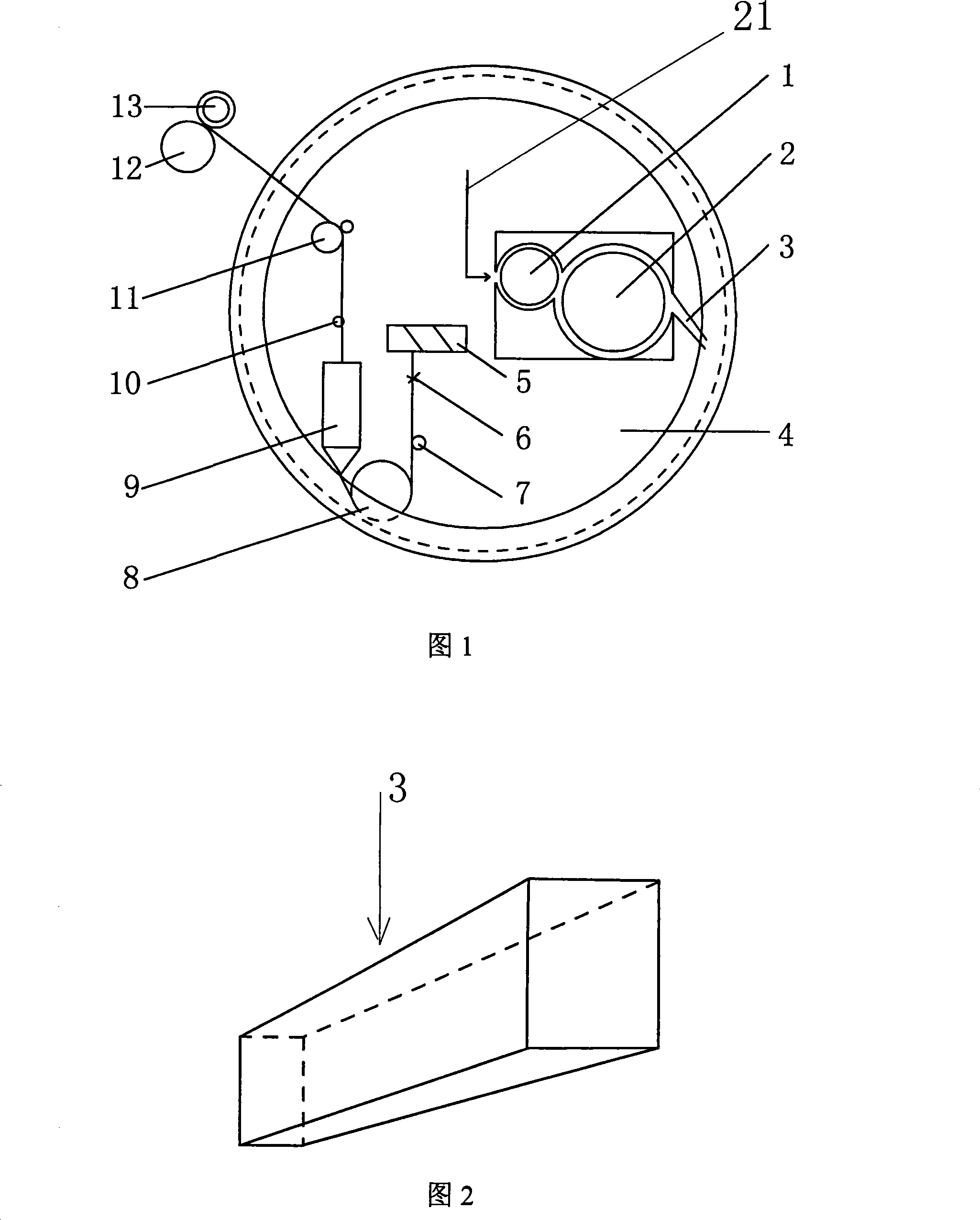

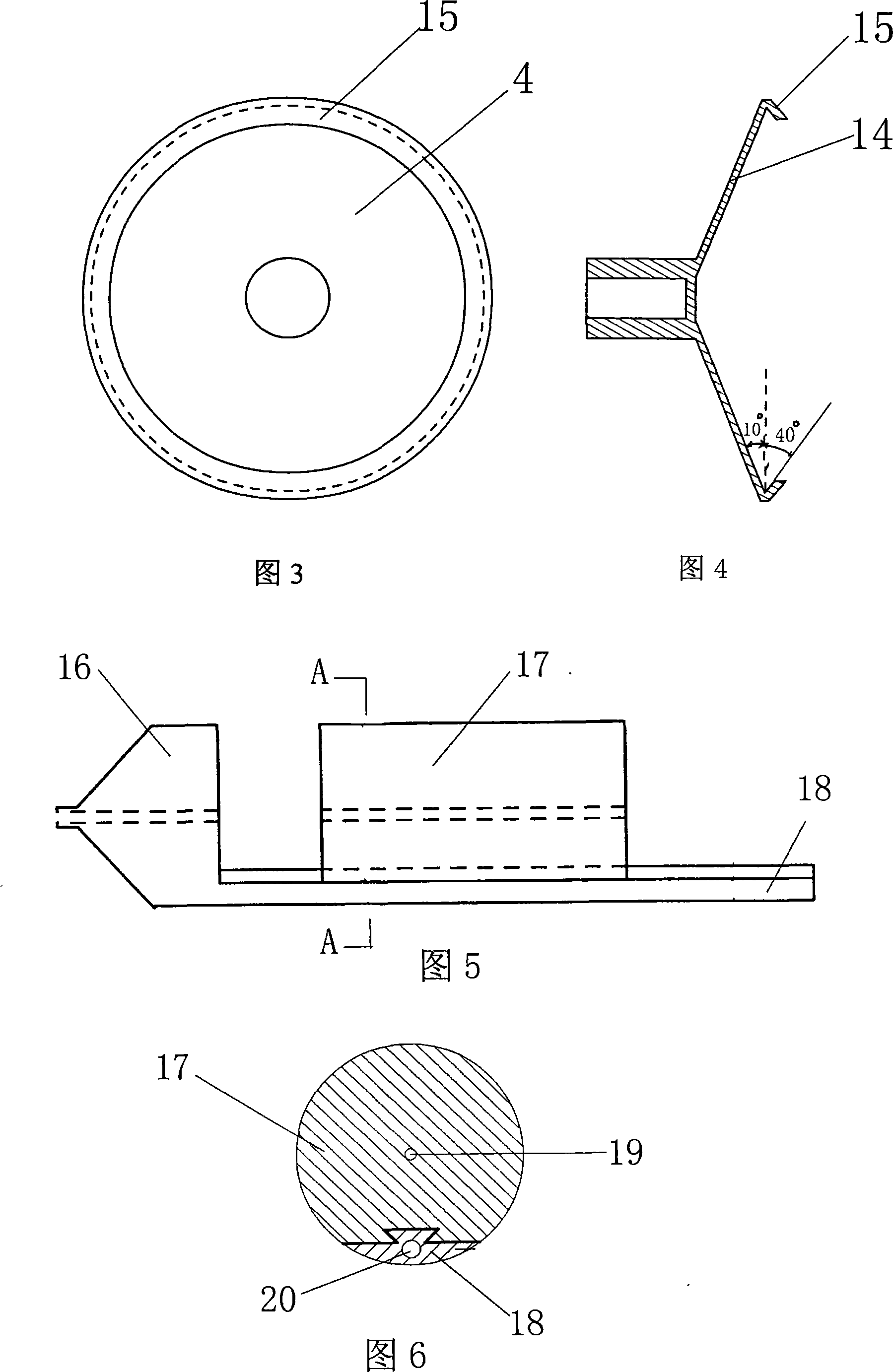

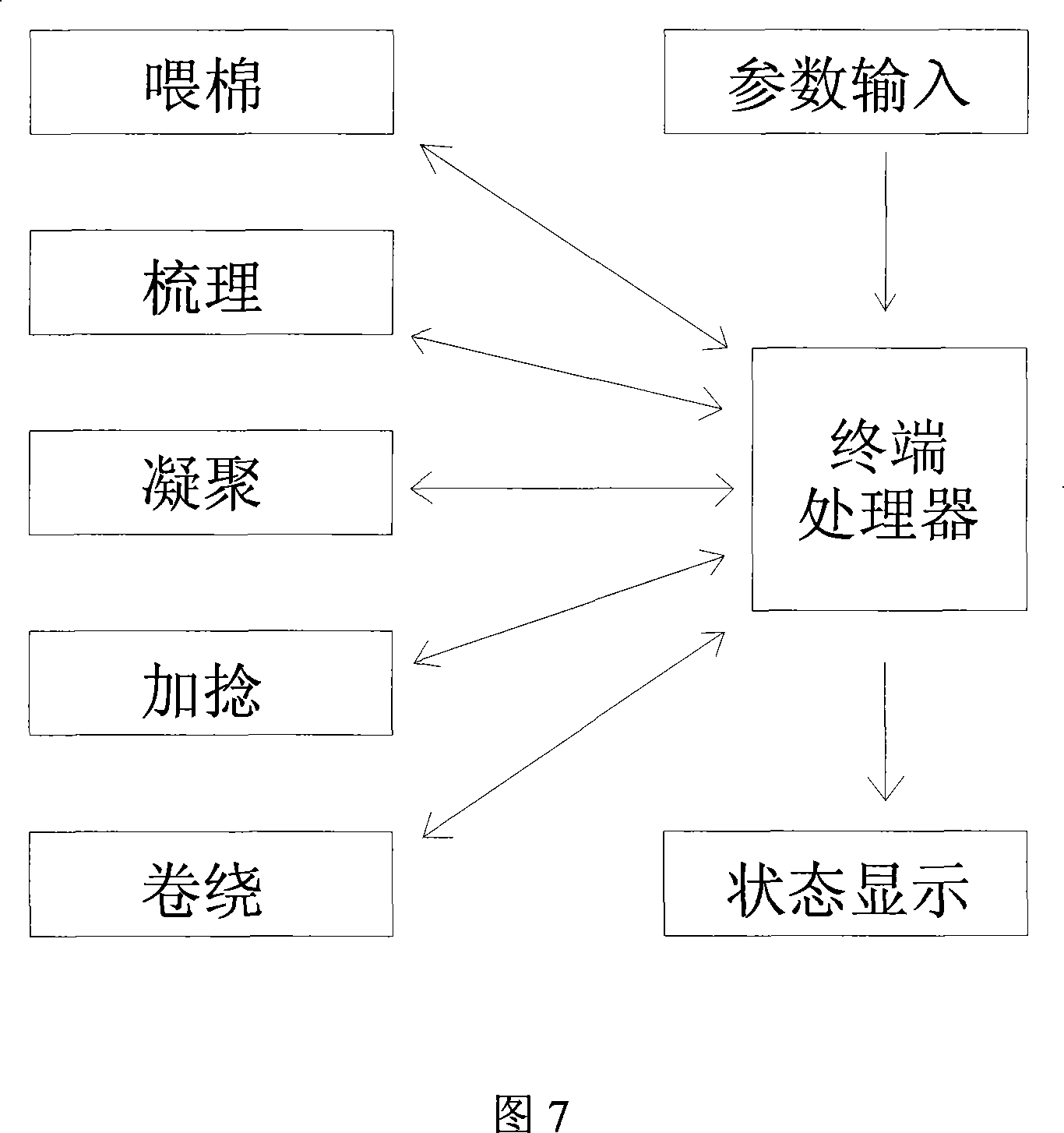

[0015] As shown in Figure 1: a cotton feeding device 1, a comb roller drafting mechanism 2, a tapered fiber conveying mechanism 3, a closed fiber gathering device 4, a swirl twister 9 and Yarn winding device; the filament frame 5, the tension device 6, the yarn guide 7 and the pressing roller 8 are arranged sequentially in the direction of travel of the filament; the sliver 21 drawn from the sliver can passes through the cotton feeding device 1 and The comb roller drafting mechanism 2 enters the closed fiber gathering device 4 through the tapered fiber conveying mechanism 3 for drafting, merging and gathering to form fiber strips, and then sends them into the swirling flow with the rotation of the closed fiber gathering device 4 Twister 9; At the same time, after the core filament drawn from the filament frame 5 passes through the tension device 6, it is sent into the swirl twister 9 through the yarn guide 7 and the pressing roller 8; the fiber strips are spun together with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com