Slurry bed reactor and Fischer-Tropsch synthesis method

A reactor and slurry bed technology, applied in the field of hydrocarbon synthesis, can solve the problems of severe catalyst wear, difficult gas-solid separation, and affecting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

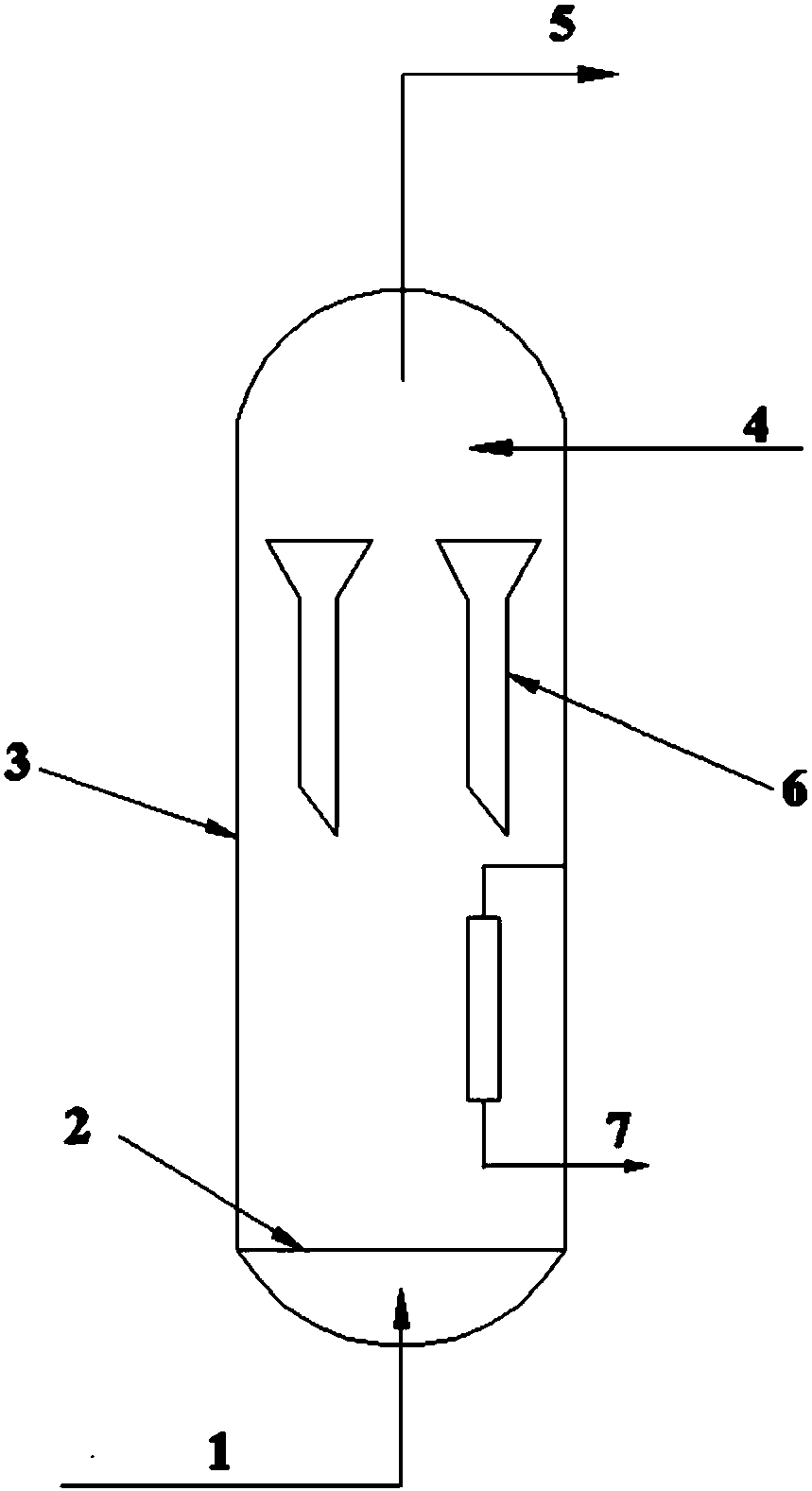

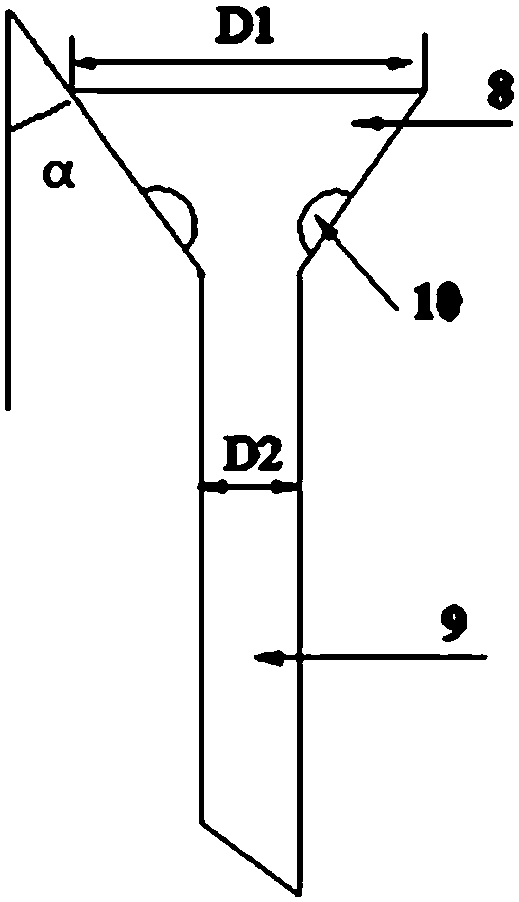

[0037] According to the present invention, it is only necessary to ensure that the degassing liquid collecting and guiding part has a funnel-shaped opening section, and there is no special requirement for a specific funnel-shaped form. According to a preferred embodiment of the present invention, the funnel-shaped opening Section 8 is tapered.

[0038] According to the present invention, the arrangement form of the diversion pipe section can be diversified, and it can be a pipe with a reduced diameter, a pipe with the same diameter, a square pipe, or a round pipe.

[0039] According to a preferred embodiment of the present invention, the diversion pipe section 9 is a straight circular pipe for diversion.

[0040] According to a more preferred embodiment of the present invention, the ratio of the diameter D1 of the tapered circular opening to the diameter D2 of the directing straight tube is 3-10.

[0041] According to the present invention, the bearing force of the degassing ...

Embodiment 1

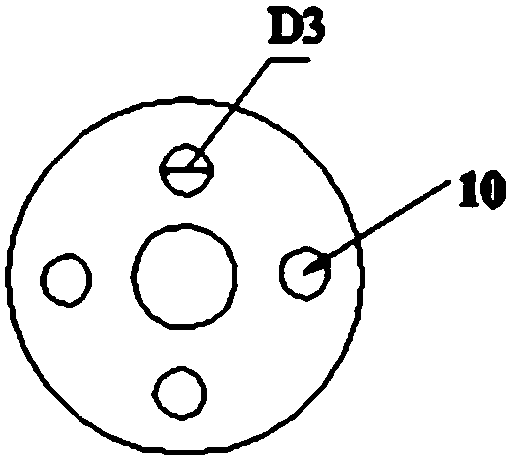

[0067] The inner diameter of the Fischer-Tropsch synthesis slurry bed reactor is 5m, and the total height of the reactor is 45m. The upper and lower layers of the slurry bed reactor are equipped with degassing liquid collection and diversion parts. The upper part of the degassing liquid collection and diversion part is conical and the lower part is Straight diversion pipe, the angle between the axis of the tapered section and the busbar is 30°, 6 diversion holes are uniformly arranged on each degassing liquid collection and diversion part, and there are 48 degassing liquid collection and diversion parts in total, each 24 layers, wherein D1=0.5m, D2=0.15m, D3=0.08m, the height ratio of the diversion pipe section 9 to the funnel-shaped opening section 8 is 5:1; The total height is 3m, with the inlet section as the starting position, the first layer of degassing liquid collecting and guiding parts is set at 23-26m of the reactor, and the second layer of degassing and liquid collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com