Funnel device with distributing and material guiding functions

The technology of a material guiding device and a funnel is applied in the field of the funnel device with the function of diverting and guiding materials, which can solve the problems of small cross-sectional area of material flow, high equipment maintenance cost, limited material transportation volume, etc., so as to save equipment investment and structure. The effect of simple, superior sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

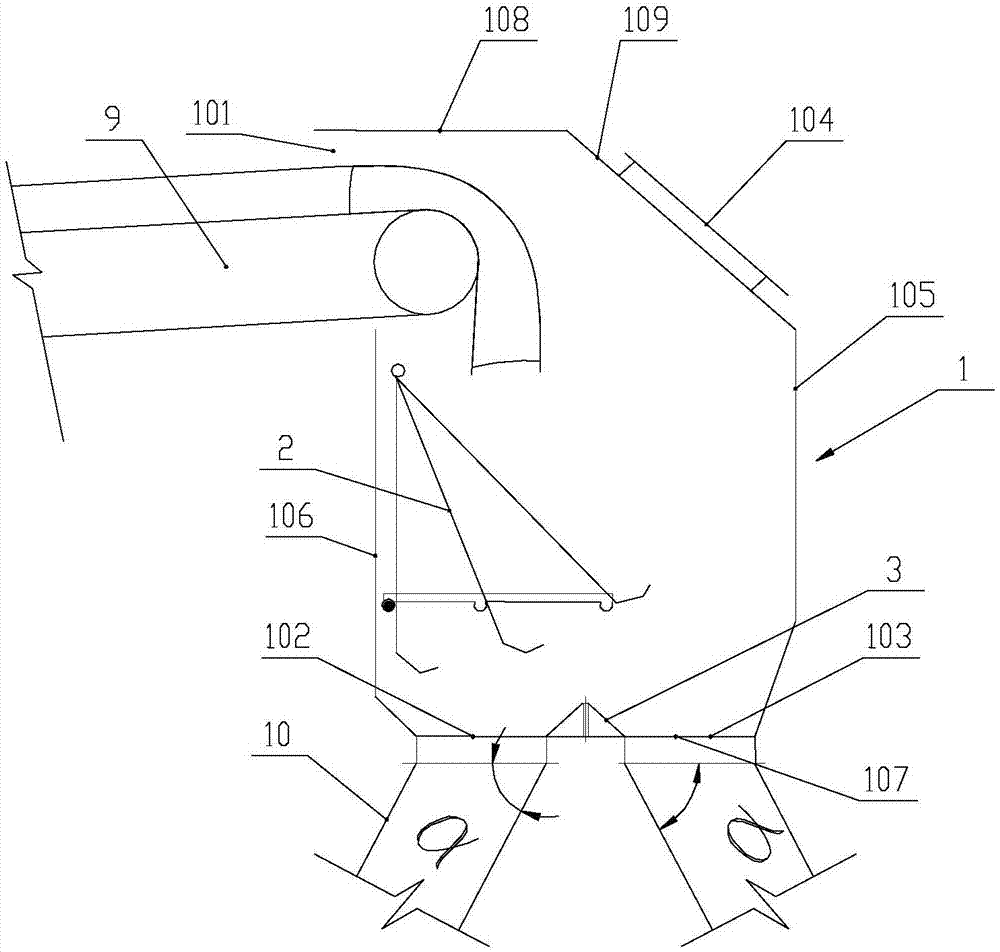

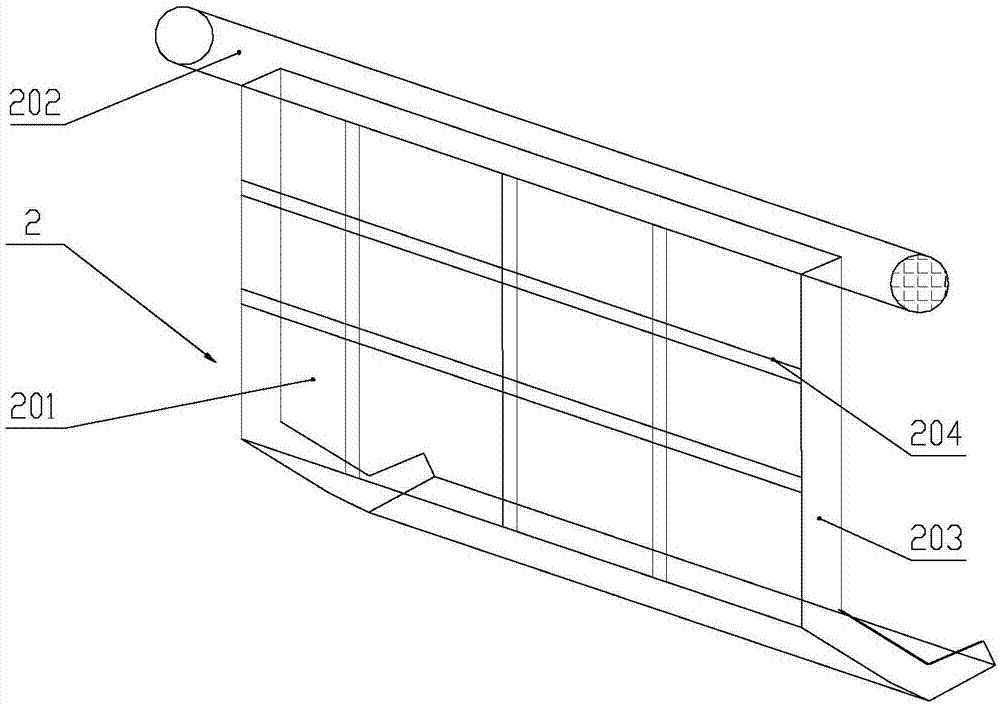

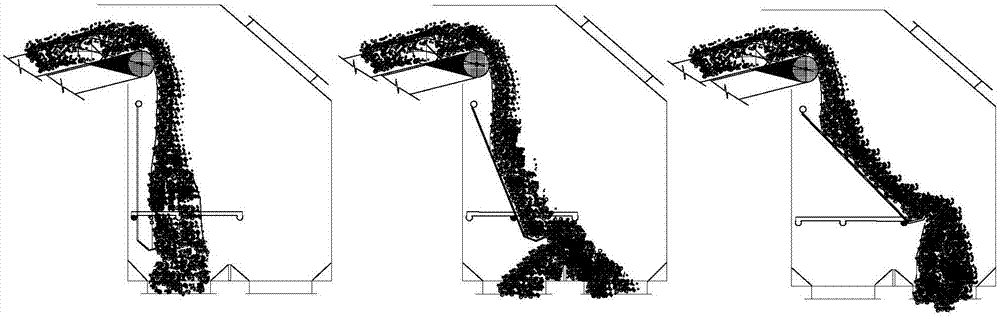

[0033] Such as figure 1As shown, the present invention is a funnel device with the function of diverting and guiding materials, which is suitable for the belt conveyor material conveying system. The funnel device of the present invention comprises a funnel 1, a material guide device 2, a partition plate 3 and a station control device. The funnel 1 has an upper material inlet 101 , and two bilaterally symmetrical lower left material outlets 102 and right lower material outlets 103 , and a ventilation and dust removal opening 104 is opened above the funnel 1 . The funnel 1 consists of a front plate 105, a back plate 106, a bottom plate 107, two side plates, an upper cover plate 108 and an upper side plate 109; , The ventilation and dust removal port can realize dust removal protection, optimize the production environment of the work area, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com