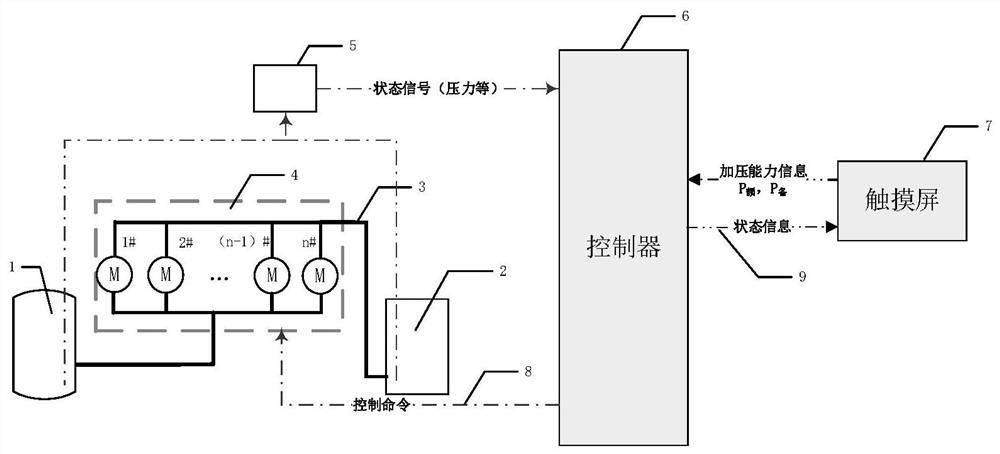

Self-adaptive control method of pressure maintaining system

An adaptive control and pressure technology, applied in the direction of fluid pressure control, electric fluid pressure control, non-electric variable control, etc., can solve the mismatch of output power of pressure maintenance equipment, increased wear and consumption of equipment originals, and affect pressure maintenance equipment. life and other issues, to achieve good control performance and economy, ensure pressure, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

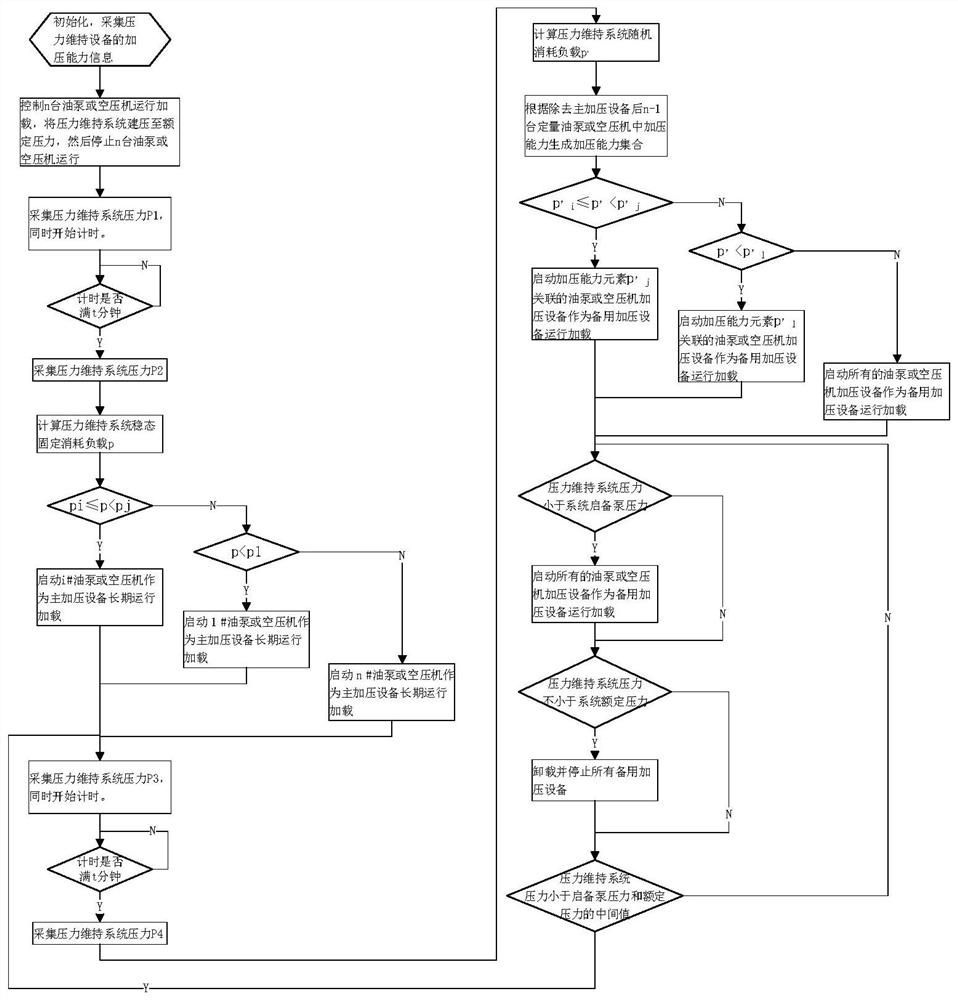

[0077] The invention is applied to the start-stop control of the pressurized oil pump of the governor hydraulic system of a certain power station. A total of 4 pressurized oil pumps are designed in this system, of which, during normal operation, 1 pump is used as the main working pump, and the remaining 3 pumps are used as backup pumps. The method of the present invention will be described in detail below in conjunction with this embodiment.

[0078] By adopting the method of the present invention, the detailed steps of the pressurized oil pump control method of the governor hydraulic system of a certain power station are as follows:

[0079] 1. The controller of the hydraulic system of the governor is initialized, and the rated pressure P set by the user through the human-computer interaction device is collected. 额 , start-up pump pressure P 备 , The pressurization capacity information corresponding to 4 pressurized oil pumps is 0.1Mpa / min, 0.2Mpa / min, 0.3Mpa / min, 0.4Mpa / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com