Wall scraping mechanism for sewage treatment tank

A technology for sewage treatment pools and sewage pools, applied in chemical instruments and methods, separation methods, sedimentation separation, etc., can solve the problems of easily broken blades and bases, increased use costs, and device damage, so as to improve practicability and adaptability performance, reduce maintenance cost, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

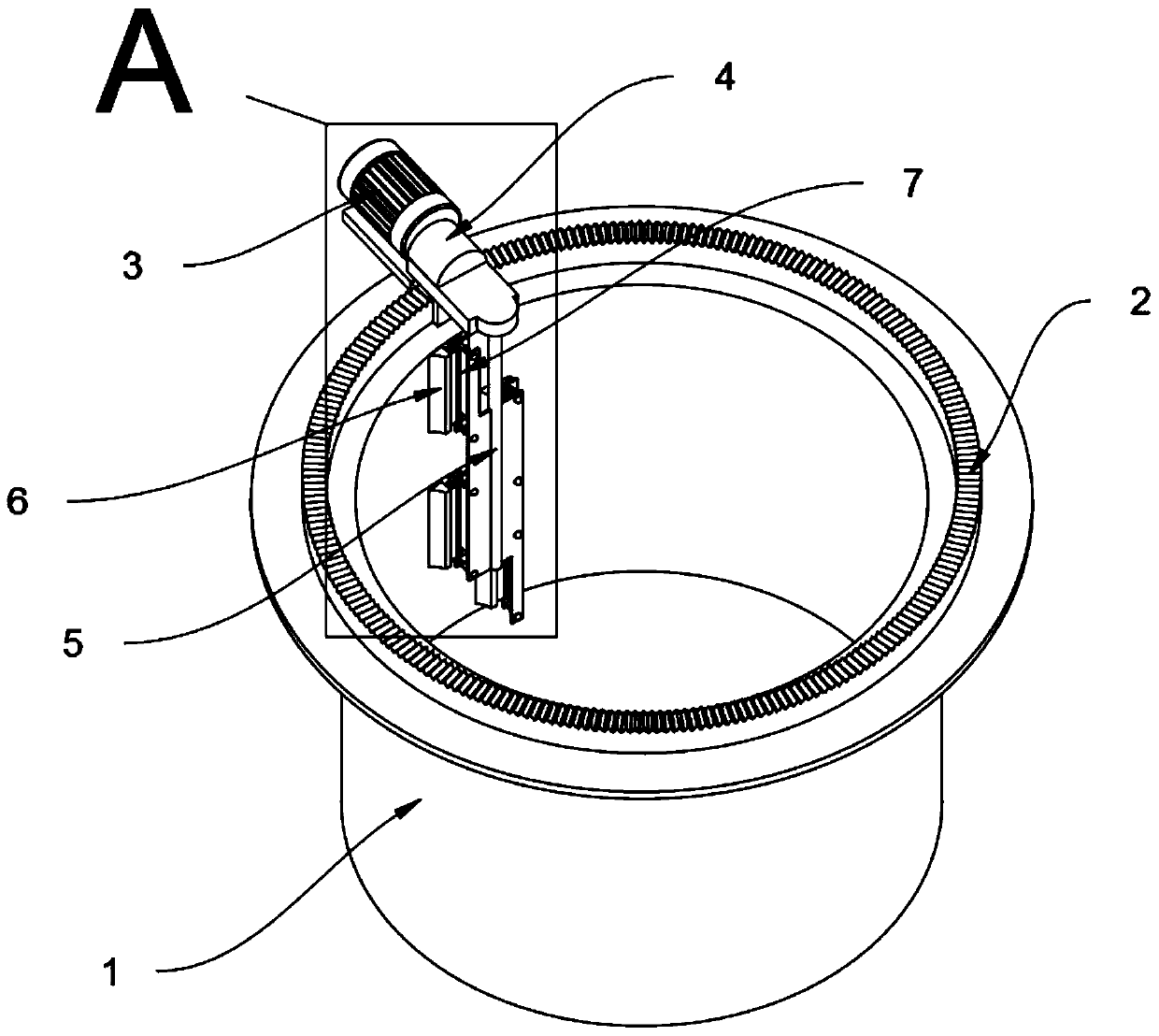

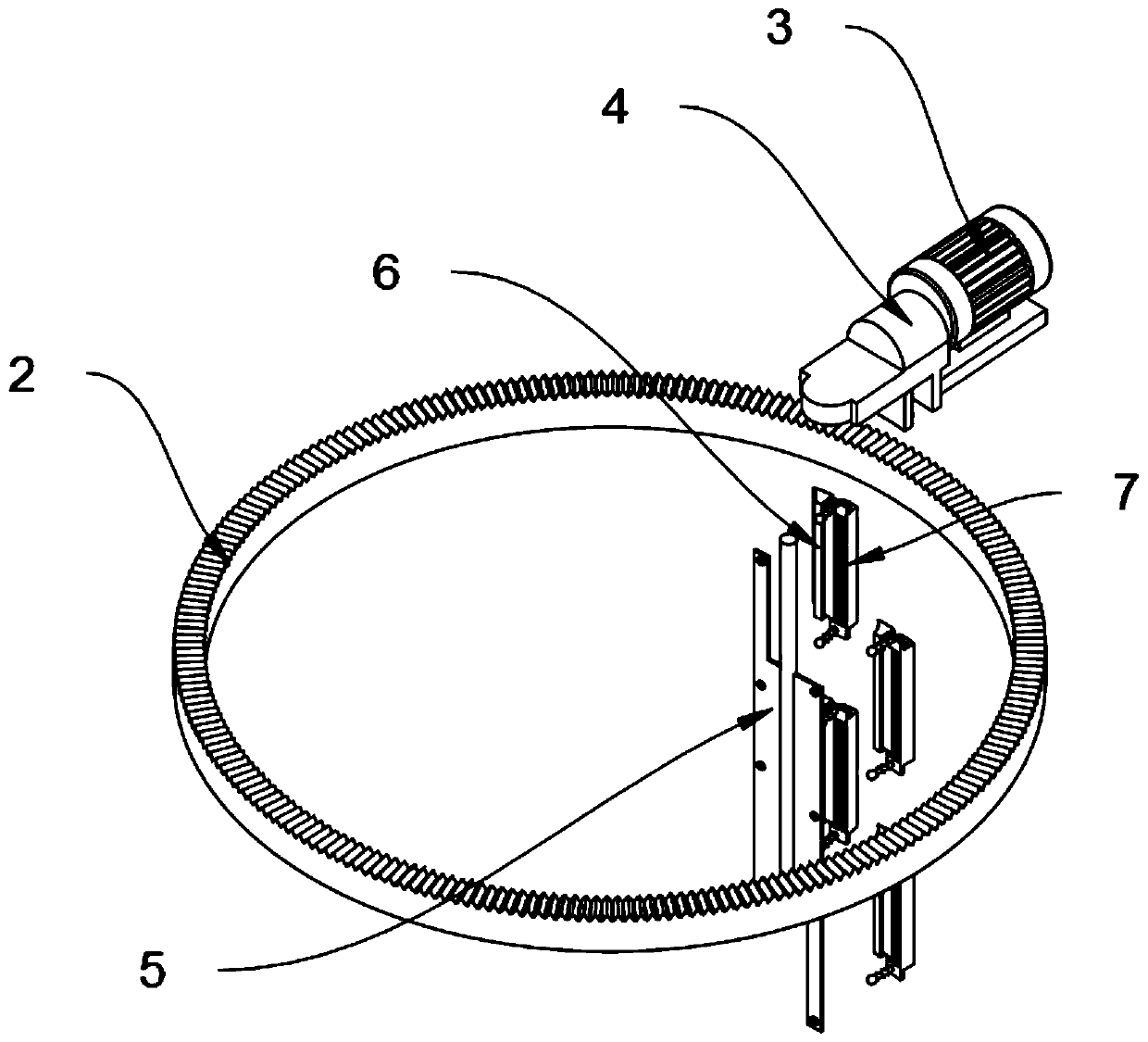

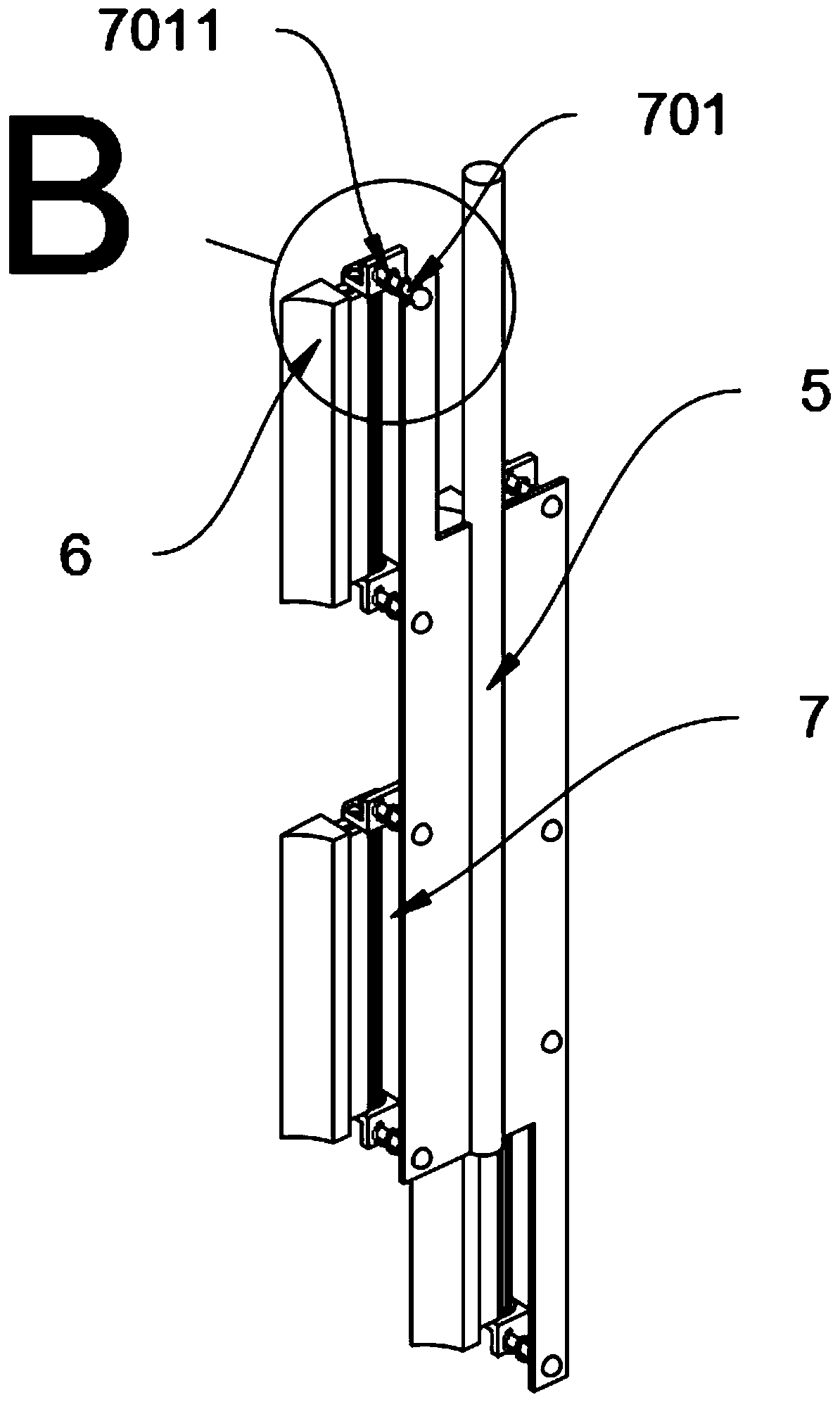

[0038] as attached figure 1 to attach Figure 11 Shown:

[0039] The invention provides a scraping mechanism for a sewage treatment pool, comprising a sewage pool 1, a drive motor 3, a support rod 5 and a scraper 6; the top of the sewage pool 1 is fixedly connected with an orbital ring 2; the drive motor 3 is fixed by screwing On the top of the track seat 4, the drive motor 3 is connected to the gear teeth of the track ring 2 through gears; the track seat 4 is clamped on the outside of the track ring 2; the support rod 5 is fixedly connected to the bottom surface of the inner end of the track seat 4; the scraper 6 Interference is plugged into the inside of the knife seat 7; the scraper 6 includes a knife body 601, a fixed axis rotating block 602 and a limit block 603, the inner surface of the knife body 601 is fixedly connected with a limit block 603, and the fixed axis rotating block 602 is inserted into the The inner surface of cutter body 601, as attached Figure 5 And a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com