Tungsten carbide-steel based composite material and preparation method thereof

A composite material and tungsten carbide technology, which is applied in the field of development and design of new materials, can solve the problems of tungsten carbide-steel matrix composite materials such as decreased strength and hardness, complicated preparation process, and reduced material performance, so as to improve wear resistance and make materials cheaper Easy to obtain and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

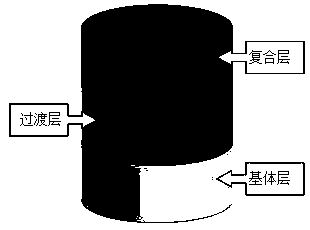

[0031] A preparation method of a tungsten carbide-steel matrix composite material in which rare earth regulates particle microscopic interface growth is as follows:

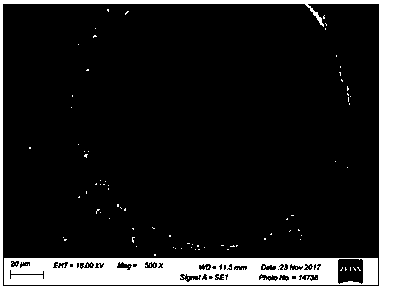

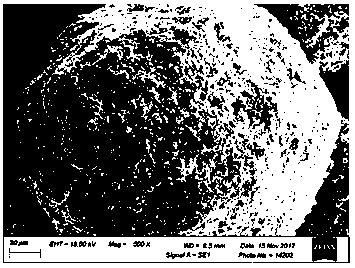

[0032] (1) Vacuum ball mill 60-mesh spherical cast tungsten carbide particles and rare earth element Y for 24 hours, so that the rare earth elements are fully attached to the surface of tungsten carbide (the scanning electron microscope picture of tungsten carbide particles with rare earth element Y is shown in figure 2 As shown, the metallographic diagram is as image 3 shown, from figure 2 and image 3 It can be seen that the rare earth element Y is evenly attached to the surface of tungsten carbide particles, and its surface energy spectrum data are shown in Table 2. It can be seen that the Y element is fully attached to the surface of tungsten carbide particles, and the content reaches 8.6%). After ball milling, use a 100-mesh sieve to remove unattached rare earth elements, and then mix them evenly with h...

Embodiment 2

[0040] A preparation method of a tungsten carbide-steel matrix composite material in which rare earth regulates particle microscopic interface growth is as follows:

[0041] (1) Mix 70-mesh spherical cast tungsten carbide particles with a mixture of rare earth elements Y and Nd and vacuum ball mill for 30 hours to make the rare earth elements fully adhere to the surface of tungsten carbide. After the ball milling, use a 100-mesh sieve to remove unattached rare earth elements , and then mixed evenly with high manganese steel powder as a composite layer material; wherein, the mass percentage of rare earth elements (Y+Nd) is 4%, the mass percentage of tungsten carbide is 42%, and the balance is high manganese steel powder;

[0042] (2) Mix tungsten powder and high manganese steel powder evenly as a transition layer material; wherein, the mass percentage of tungsten powder is 35%, and the balance is high manganese steel powder;

[0043] (3) The base layer material is high manganes...

Embodiment 3

[0047] A preparation method of a tungsten carbide-steel matrix composite material in which rare earth regulates particle microscopic interface growth is as follows:

[0048] (1) Mix 80-mesh spherical cast tungsten carbide particles with rare earth element Ta and vacuum ball mill for 40 hours to make the rare earth elements fully adhere to the surface of tungsten carbide. The steel powder is mixed uniformly as a composite layer material; wherein, the mass percentage of the rare earth element Ta is 2%, the mass percentage of tungsten carbide is 50%, and the balance is 45% steel powder;

[0049] (2) Mix tungsten powder and 45 steel powder evenly as a transition layer material; wherein, the mass percentage of tungsten powder is 40%, and the balance is 45 steel powder;

[0050] (3) The base layer material is 45 steel powder;

[0051] (4) The three materials were ball milled for 1 hour, and then pressed into a three-layer prefabricated body with a tablet press according to the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com