Fluidized bed biological filler, preparation method thereof and flowing composite active microbe biological bed

A technology of biological filler and fluidized bed, which is applied in the field of flowing compound active biological bacteria biological bed, can solve the problems of prolonging sewage treatment time, multiple time and resources, and many steps, and achieve long service life, good chemical stability, and easy The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

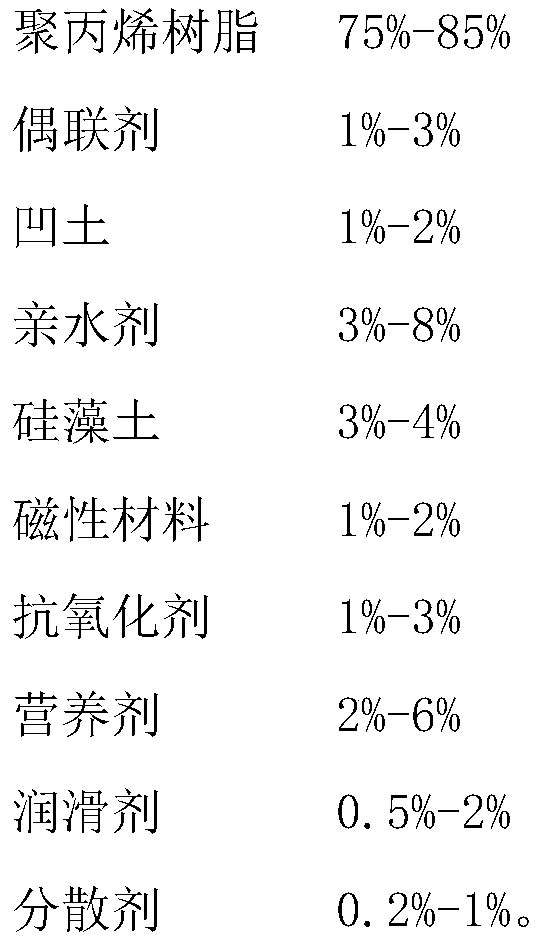

[0037] A fluidized bed biological filler, consisting of the following components (g),

[0038]

[0039]

[0040] Wherein the coupling agent is a silane coupling agent, the hydrophilic agent is stearic acid, the antioxidant is antioxidant 1010, and the nutritional agent is bagasse.

[0041] Its preparation method is

[0042] Sp1: Put polypropylene particles, attapulgite, hydrophilic agent, diatomaceous earth, magnetic material, antioxidant, nutrient, and dispersant into the stirring device and stir evenly;

[0043] Sp2: Blend the uniformly stirred materials, lubricants and coupling agents in a kneader at a kneading temperature of 140°C, and then obtain semi-finished fillers by injection molding in an injection molding machine at a temperature of 160°C;

[0044] Sp3: Magnetize the obtained semi-finished filler in a magnetizer to make the semi-finished filler obtain magnetism to obtain a finished biological filler.

Embodiment 2

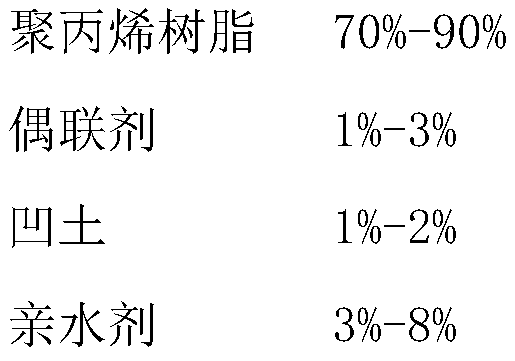

[0046] A fluidized bed biological filler, consisting of the following components (g),

[0047]

[0048] Wherein the coupling agent is a silane coupling agent, the hydrophilic agent is polyacrylamide, the antioxidant is antioxidant TPP, and the nutritional agent is chitin.

[0049] Its preparation method is

[0050] Sp1: Put polypropylene particles, attapulgite, hydrophilic agent, diatomaceous earth, magnetic material, antioxidant, nutrient, and dispersant into the stirring device and stir evenly;

[0051] Sp2: Blend the uniformly stirred materials, lubricant and coupling agent in a mixer with a kneading temperature of 145°C, and then obtain semi-finished fillers by injection molding in an injection molding machine with an injection temperature of 165°C;

[0052] Sp3: Magnetize the obtained semi-finished filler in a magnetizer to make the semi-finished filler obtain magnetism to obtain a finished biological filler.

Embodiment 3

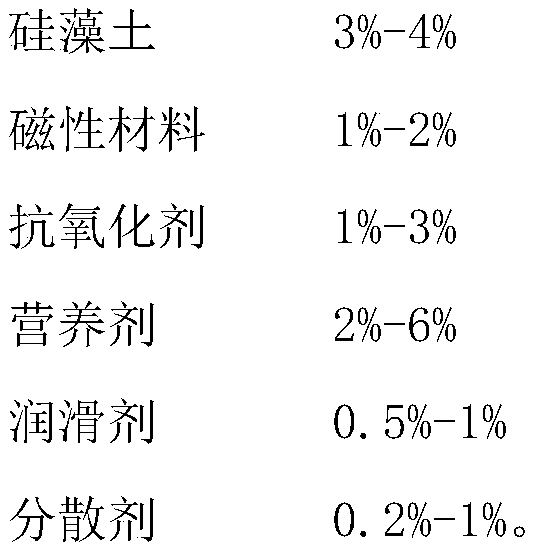

[0054] A fluidized bed biological filler, consisting of the following components (g),

[0055]

[0056] Wherein the coupling agent is aluminate, the hydrophilic agent is , the antioxidant is antioxidant 1076, and the nutrient is lignin.

[0057] Its preparation method is

[0058] Sp1: Put polypropylene particles, attapulgite, hydrophilic agent, diatomaceous earth, magnetic material, antioxidant, nutrient, and dispersant into the stirring device and stir evenly;

[0059] Sp2: Blend the uniformly stirred materials, lubricants and coupling agents in a mixer with a kneading temperature of 150°C, and then obtain semi-finished fillers by injection molding in an injection molding machine with an injection temperature of 170°C;

[0060] Sp3: Magnetize the obtained semi-finished filler in a magnetizer to make the semi-finished filler obtain magnetism to obtain a finished biological filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com