Dipping or high-dipping thin ore cantilever-type tunneling machine ore breaking continuous mining method

A mining method and roadheader technology, applied in ground mining, mining equipment, underground mining, etc., can solve difficult problems such as unsteady inclined or steeply inclined thin ore body mining, and achieve small disturbance of surrounding rock and equipment movement Convenience and high rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] Inclined or sharply inclined thin ore body cantilever type roadheader continuous mining method for falling ore of the present invention, its preferred embodiment is:

[0023] include:

[0024] The entire set of mining methods implemented around a single mining operation face can be operated in parallel at the same time, and the entire set of mining methods includes mechanical ore falling, goaf filling, ore extraction and support operations;

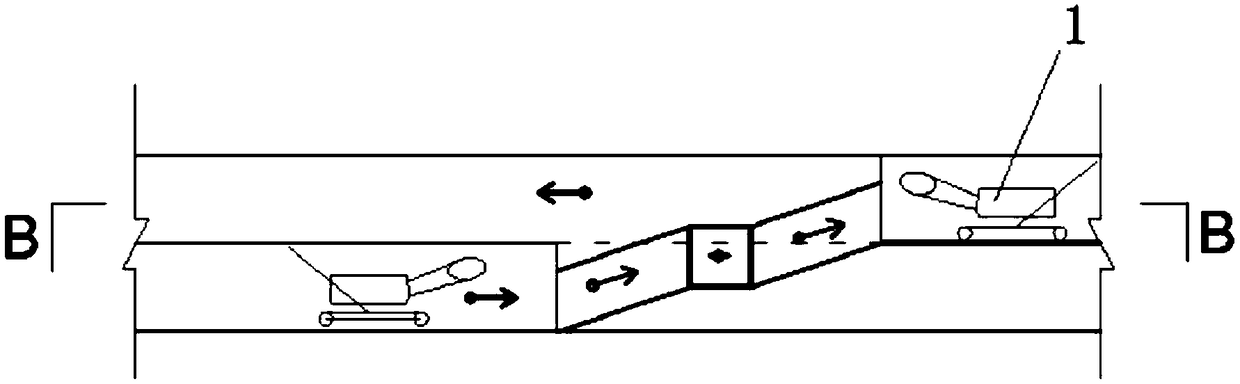

[0025] When the roadheader is transferred from the end of the ore body to the upper part of the layer for mining, the Y-shaped mining engineering is used to transfer layers and turn around. The turning radius of the Y-shaped layer-transfer mining engineering is ≥ 6m. In the Y-shaped layer transfer mining project, the machine moves forward twice and retreats once to complete the U-turn. The starting slope of the Y-shaped layer transfer mining project is between 10° and 15° to ensure the smooth layer transfer of the equipment;

[00...

specific Embodiment

[0046] Such as Figure 1 to Figure 4 As shown, the specific steps are as follows:

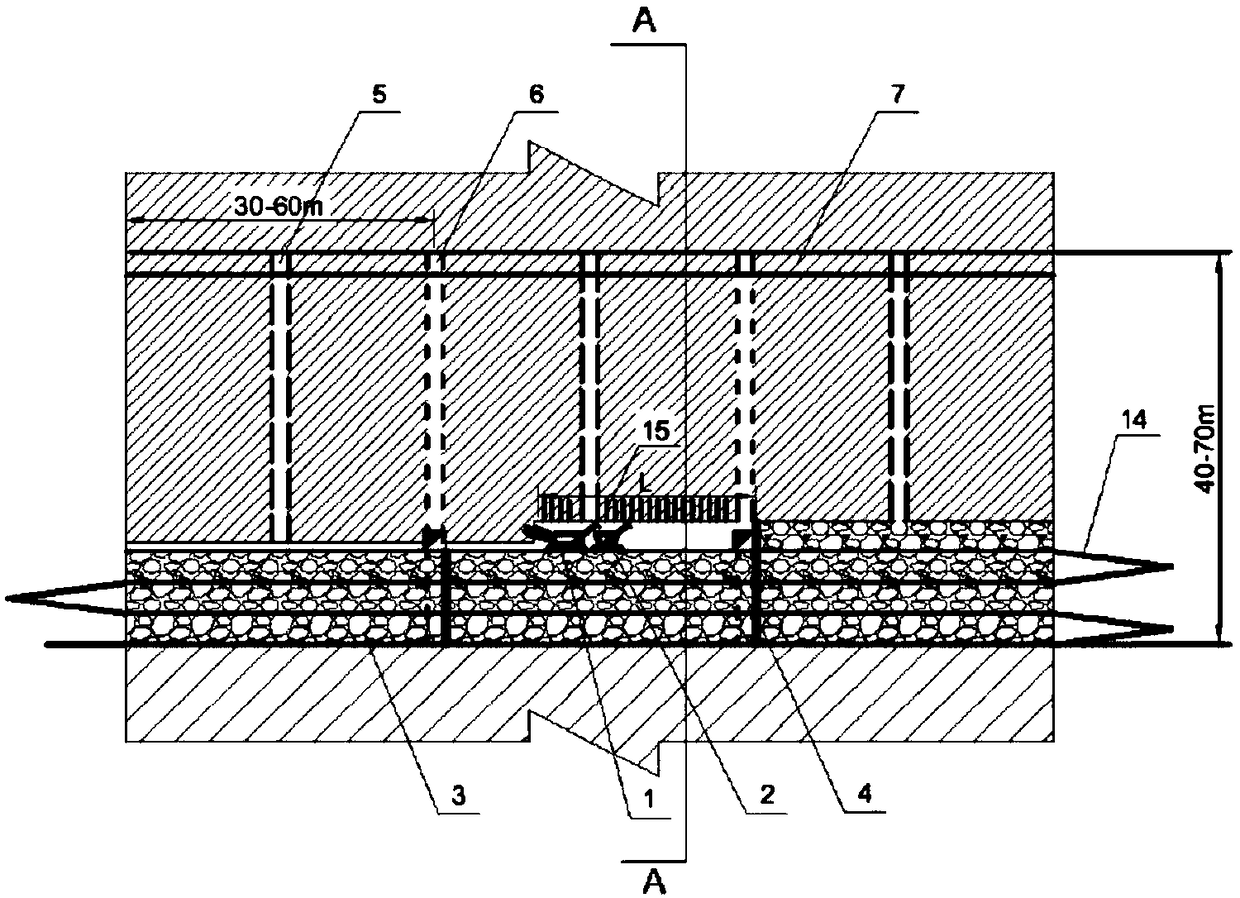

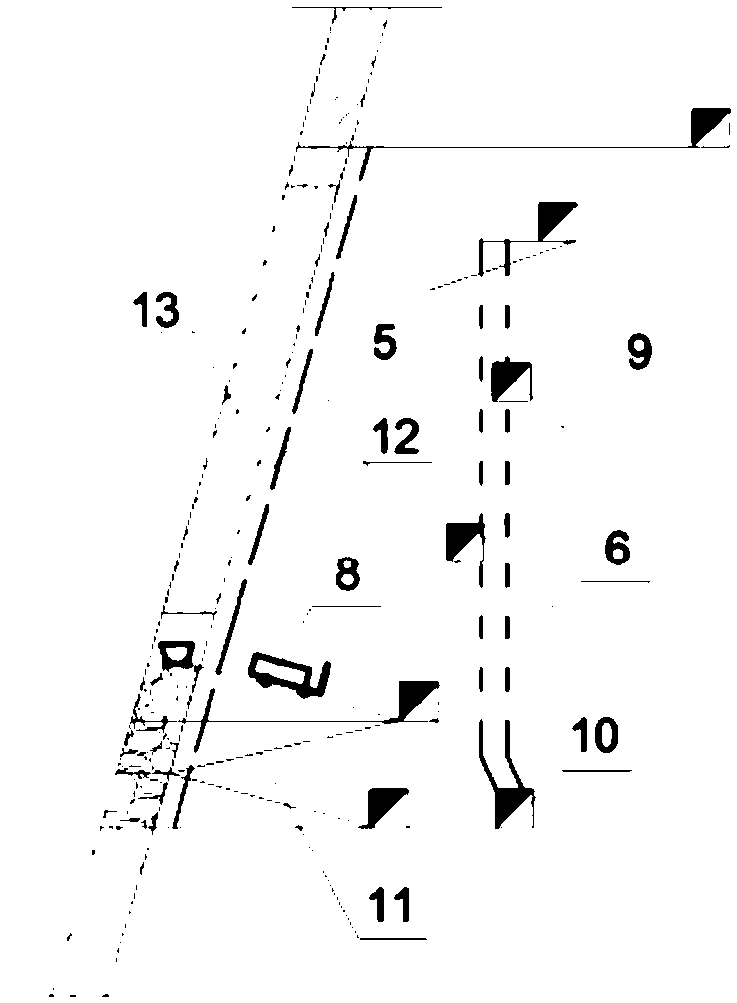

[0047] (1) Divide stopes at intervals of 30m to 60m along the direction of ore body 13, with a height of 40m to 70m in the middle section, and use roadheaders to mine from bottom to top. Arrange filling shaft 5, chute 6 (ore chute, waste rock chute), mid-section drift 10, subsection drift 12 at the footwall of the ore body. According to the climbing ability of the trackless mine car 8 and the requirement of a sub-level entry 12 serving 3 to 4 excavation layers, the sub-level entry 12 is excavated from the sub-level entry 12 and the layered connection road 11 is accessible to the ore body for pedestrians, material transportation, Power supply, mining, ventilation, etc.

[0048] (2) The roadheader 1 excavates from one end of the ore body 13 to the other end, turns around in the equipment department in the same layer, and turns around at the end through the equipment layer transfer road 14 to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com