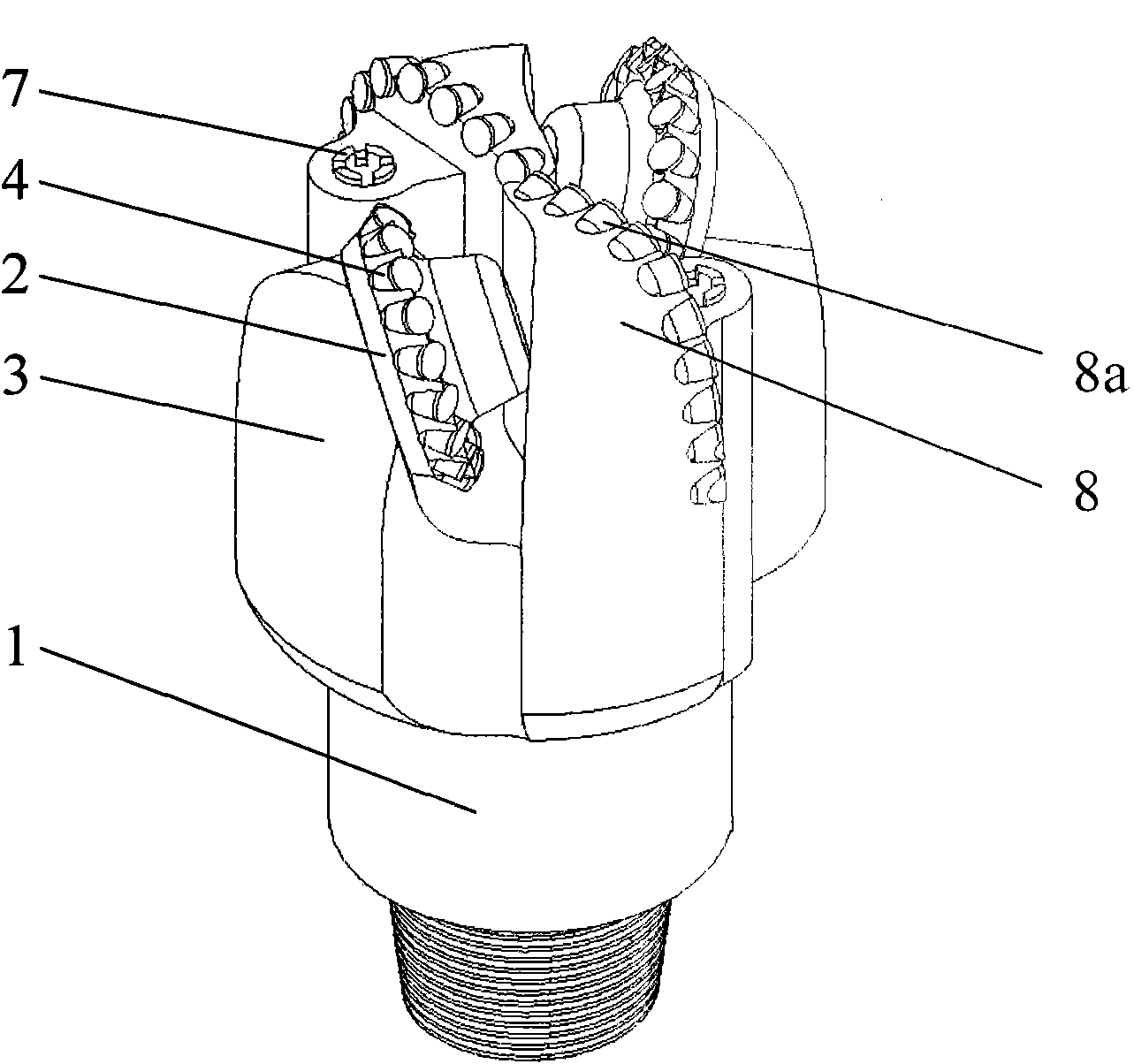

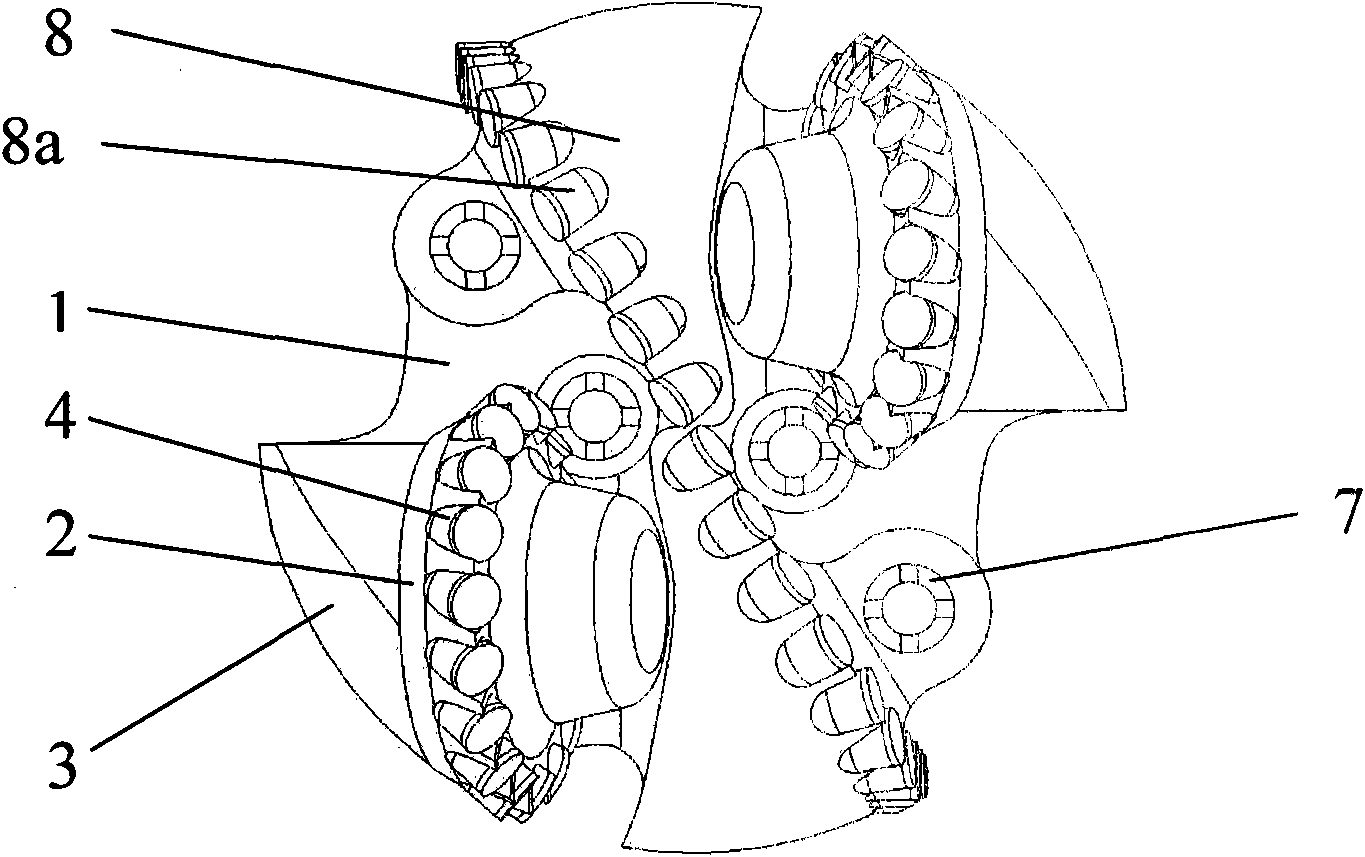

Combined drill breaking rocks by cutting method

一种复合式、钻头的技术,应用在钻头、土方钻采、钻井设备等方向,能够解决增加PDC齿工作负荷、钻头失效、加快磨损速度等问题,达到提高破岩效率、磨损均匀、延长使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

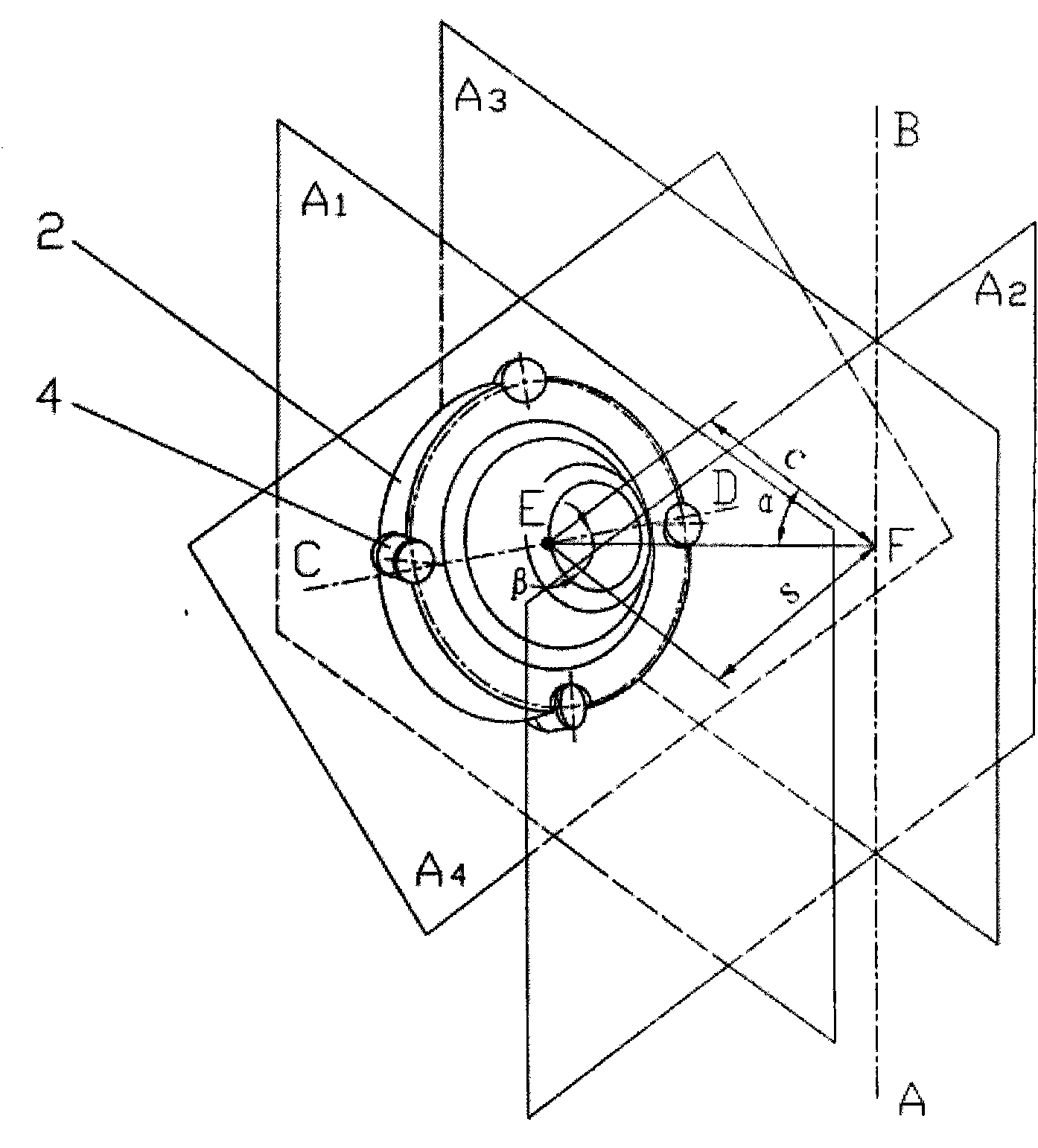

[0066] When the offset angle of the runner 2 is α=±20°, a drill with an outer diameter D=8.5 inches (215.9 mm) is taken as an example (the point farthest from the drill axis on the runner is the drill gauge diameter point). Take the radius r of the outer cutting ring gear 4 of the runner 2 to be 65mm, and the shaft inclination angle β of the runner 2 = 0°, because

[0067] s=c·tan|α| (1)

[0068] ( D 2 ) 2 = ( r + s ) 2 + c 2 - - - ( 2 )

[0069] From equations (1) and (2), it can be obtained that the reference distance c=62.75mm, and the wheel shifting wheel distance s=22.84mm.

[0070] Under the above parameters, the amount of radial slip of the cutting teeth on the outer cutting ring gear 4 of the runner 2 from cutting in to cutting out the bottom hole rock is 41.17mm. According to theoretical calculations and actual experiments that have been done, it can be concluded that the wheel speed ratio at this time is below 0.96...

Embodiment 2

[0074] When the offset angle of the runner 2 is α=±30°, the drill with the outer diameter D=215.9 mm is still taken as an example. Take the radius r of the outer cutting gear ring 4 of the runner as 65 mm.

[0075] According to formulas (1) and (2), the reference distance c=51.62mm, and the wheel distance s=29.81mm of the runner 2.

[0076] Under the above parameters, the radial slip of the cutting teeth is 48.34mm. According to theoretical calculations and actual experiments that have been done, it can be concluded that the wheel speed ratio at this time is below 0.79, and the cutting teeth on the runner 2 can be slowly and alternately moved at the bottom of the well to scrape or cut the rock in turn. . Such as Figure 13 Shown is a schematic diagram of the net-like scratches cut by the drill bit at the bottom of the well under the combined action of the runner cutting unit and the fixed cutting structure when the offset angle of the runner 2 of the present invention is α=30°. ...

Embodiment 3

[0078] When the offset angle of the runner 2 is α=±40°, the values of D and r are the same as above, substituting equations (1) and (2) to obtain, c=41.37mm, s=34.71mm.

[0079] Under the above parameters, the radial slip of the cutting teeth is 53.95mm, and the wheel speed ratio is below 0.64. Such as Figure 14 Shown is a schematic diagram of the net-like scratches cut by the drill bit at the bottom of the well under the combined action of the rotating wheel cutting unit and the fixed cutting structure when the offset angle of the runner 2 of the present invention is α=40°. It can be seen from the figure that the sliding amount of the cutting teeth on the runner at the bottom of the well is longer than when α=±30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com