Biomass fuel crushing device

A biomass fuel and pulverizing device technology, applied in grain processing and other directions, can solve the problems of low pulverizing efficiency and slow pulverizing speed, and achieve the effects of fast pulverizing speed, good pulverizing effect and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

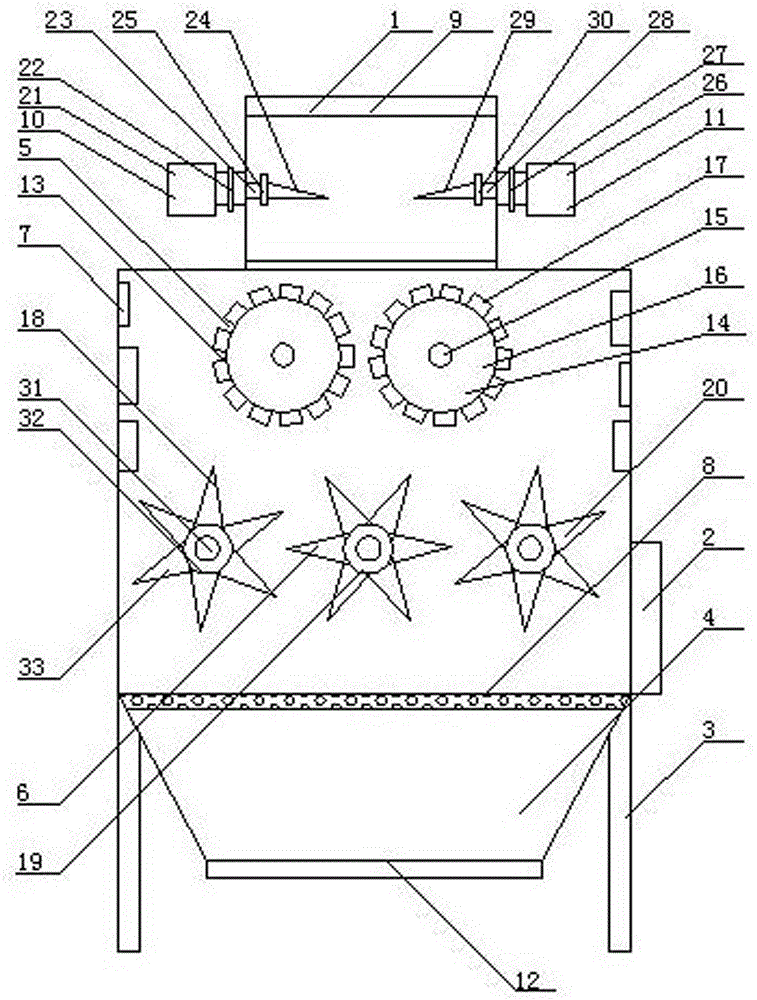

[0018] As shown in the figure, a biomass fuel crushing device includes a fuselage, a feeding mechanism 1 is installed on the top of the fuselage, a discharge door 2 is installed on the lower end of the right side of the fuselage, and a support is installed on the left and right sides of the bottom of the fuselage Leg 3, the bottom end of the fuselage is equipped with a conical discharge bin 4, the upper end of the fuselage is equipped with a roller grinder 5, the lower end of the fuselage is equipped with a combined grinder 6, and the upper ends of the left and right sides of the fuselage are equipped with multiple irregularities. Baffle plate 7, stainless steel strainer 8 of fuselage inner bottom device.

[0019] A feeding door 9 is installed at the top of the feeding mechanism 1 , and a first section cutting device 10 and a second section cutting device 11 are respectively installed on the left and right sides of the inside of the feeding mechanism 1 .

[0020] A discharge p...

Embodiment 2

[0027] Further, the rectangular extruding bar 17 outside the left shredder 13 engages with the rectangular extruding bar 17 outside the right shredder 14 .

Embodiment 3

[0029] Further, the triangular sharp knives 33 outside the first pulverizing knife set 18 , the second pulverizing knife set 19 , and the third pulverizing knife set 20 are engaged with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com