Microporous preservative BOPP film and preparation method thereof

A microporous and thin-film technology, which is applied in the field of microporous fresh-keeping BOPP film and its preparation, can solve problems such as the inability to quickly and fully adjust the atmosphere ratio of packaging bags, the inability to achieve average control of the atmosphere in the packaging, and the inability to meet the requirements of fresh-keeping packaging for fruits and vegetables. Reduce the effect of bacterial growth and reproduction, reduce bacterial growth, and reduce the phenomenon of burnt edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

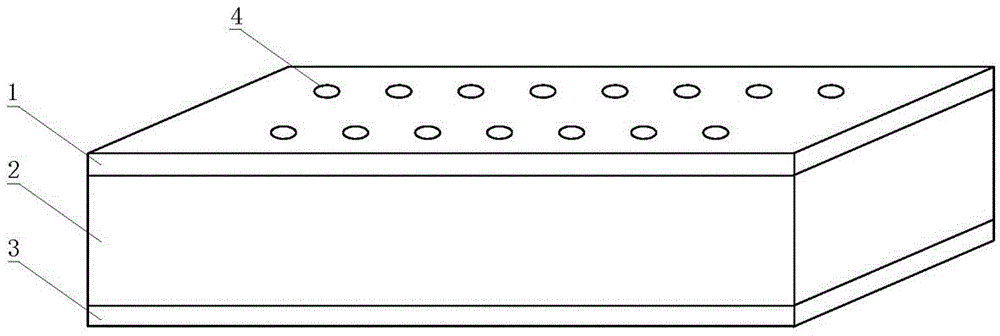

[0033] like figure 1 As shown, the present invention provides a microporous fresh-keeping BOPP film, comprising an upper surface layer 1, a core layer 2, and a lower surface layer 3, the upper surface of the core layer 2 is provided with an upper surface layer 1, and the lower surface of the core layer 2 is provided with a lower surface layer 3. The surface of the upper surface layer 1 and the lower surface layer 3 is evenly provided with a preset number of laser-drilled holes with a diameter of 10um and a micropore density of 30 / cm 2 microwell 4;

[0034] The microporous fresh-keeping BOPP film is made of the following raw materials in parts by weight: based on 1000 parts in total, homopolypropylene: 794.78 parts, antistatic agent: 28 parts, stiffener: 177 parts, anti-blocking Dosage: 0.22 parts;

[0035] Among them, the upper surface layer is an anti-blocking layer, accounting for 56 parts in total, of which homopolypropylene: 55.89 parts, and anti-blocking agent 0.11 part...

Embodiment 2

[0051] The present invention provides a microporous fresh-keeping BOPP film, comprising an upper surface layer 1, a core layer 2, and a lower surface layer 3, an upper surface layer 1 is arranged on the upper surface of the core layer 2, and a lower surface layer 3 is arranged on the lower surface of the core layer 2, and the upper surface layer The surface of 1 and the lower surface layer 3 is uniformly provided with a preset number of laser-drilled holes with a diameter of 10um and a micropore density of 30 / cm 2 microwell 4;

[0052] The microporous fresh-keeping BOPP film is made of the following raw materials in parts by weight: based on 1000 parts in total, homopolypropylene: 794.86 parts, antistatic agent: 28 parts, stiffener: 177 parts, anti-blocking Dosage: 0.14 parts;

[0053] Among them, the upper surface layer is an anti-blocking layer, accounting for 56 parts in total, of which homopolypropylene: 55.93 parts, and anti-blocking agent 0.07 parts;

[0054] The core ...

Embodiment 3

[0060] The present invention provides a microporous fresh-keeping BOPP film, comprising an upper surface layer 1, a core layer 2, and a lower surface layer 3, an upper surface layer 1 is arranged on the upper surface of the core layer 2, and a lower surface layer 3 is arranged on the lower surface of the core layer 2, and the upper surface layer The surface of 1 and the lower surface layer 3 is uniformly provided with a preset number of laser-drilled holes with a diameter of 10um and a micropore density of 30 / cm 2 microwell 4;

[0061] The microporous fresh-keeping BOPP film is made of the following raw materials in parts by weight: based on 1000 parts in total, homopolypropylene: 794.94 parts, antistatic agent: 28 parts, stiffener: 177 parts, anti-blocking Dosage: 0.06 parts;

[0062] Among them, the upper surface layer is an anti-blocking layer, accounting for 56 parts in total, of which homopolypropylene: 55.97 parts, and anti-blocking agent 0.03 parts;

[0063] The core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com