Preparation method of edible mushroom seasoning

A technology for edible fungi and condiments, which is applied in the field of preparation of edible fungi condiments, can solve the problems of not effectively retaining the flavor substances of edible fungi, and achieve the effects of improving market applicability and economic value, high production capacity, and outstanding flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

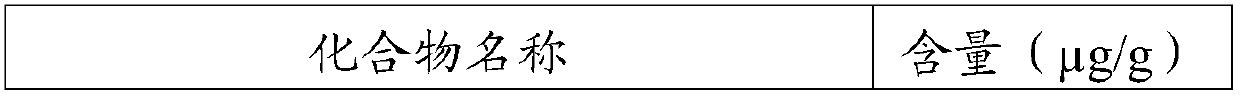

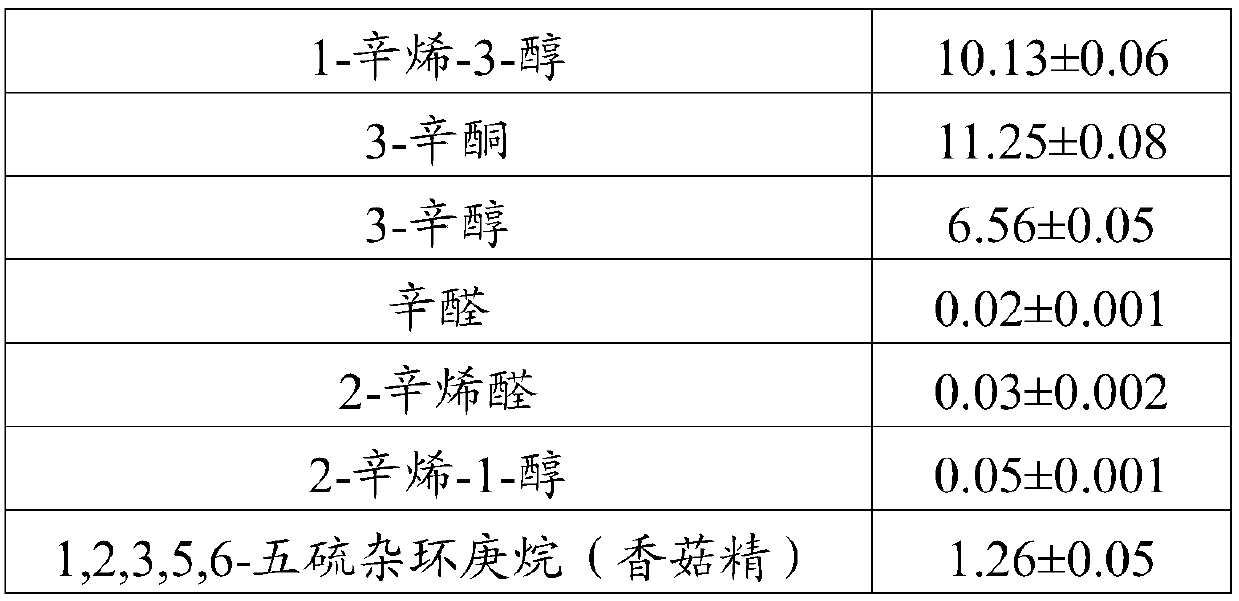

Image

Examples

preparation example Construction

[0035] The method for preparing edible mushroom seasoning and batching provided by the invention comprises the following steps:

[0036] 1) After cleaning the edible fungus, crushing and enzymatic hydrolysis;

[0037] 2) Embedding and drying the semi-finished product obtained in step 1) to obtain the edible mushroom condiment and ingredients.

[0038] In the step 1) of the above method, aiming at the problems that the edible fungus is difficult to be crushed evenly, and the overheating of the dry crushing causes a large loss of flavor components, etc., the edible fungus homogeneous liquid is prepared by using high-density liquid grinding and other wet crushing techniques for homogenization;

[0039] In the crushing step, it should be ensured that the obtained homogeneous liquid has a uniform texture and no particles;

[0040] In the enzymolysis step, 6000U-30000U papain, 300U-1500U flavor protease, 400U-1200U cellulase, 500U-2500U xylanase were added per unit mass, and the mi...

Embodiment 1

[0051] The preparation method of mushroom condiment comprises steps:

[0052] S1. Raw material pretreatment: select fresh shiitake mushrooms that are mature, free from rot, pests and diseases, and mechanical damage, clean them, and dice them;

[0053] S2, wet pulverization: mix diced shiitake mushrooms with drinking water in a weight ratio of 4:1, use a beater, a colloid mill, and a homogenizer in turn to beat and homogenize to obtain a homogeneous liquid of shiitake mushrooms, which can Pass 150 mesh sieve;

[0054] S3. Enzymolysis: Add papain, flavor protease, cellulase, and xylanase to the mushroom homogeneous liquid, and treat at 300Mpa with ultra-high pressure for 5 minutes; under natural pH conditions, react at 55°C for 1 hour; the end of enzymolysis Finally, passivate at 95°C for 15 minutes to obtain an enzymatic hydrolysis solution; the amount of papain added is 30000U / g 香菇均质液 , the added amount of flavor enzyme is 1500U / g 香菇均质液 , the amount of cellulase added is 80...

Embodiment 2

[0062] The preparation method of tea tree mushroom condiment comprises steps:

[0063] S1. Raw material pretreatment: select dry tea tree mushrooms that are clean, without mechanical damage, and whose moisture content meets the national standard, and chop them up after rehydration;

[0064] S2. Wet pulverization: Mix tea tree mushroom and drinking water in a weight ratio of 9:1, use a wall breaking machine, a colloid mill, and a homogenizer in sequence for beating and homogenizing to obtain a tea tree mushroom homogeneous liquid, and the homogenization Liquid can pass through 100 mesh sieve;

[0065] S3, enzymatic hydrolysis: add 6000U papain, 3000U flavor protease, 1200U cellulase, 2500U xylanase to each gram of tea tree mushroom homogeneous liquid obtained in step S2, and ultrasonically treat for 30min under 50w power; under natural pH conditions , reacted at 45°C for 4h; after the enzymolysis, passivated at 90°C for 15min to obtain the enzymolysis solution;

[0066] S4. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com