Adjustable Volume Rigid Container

a container and volume technology, applied in the direction of containers preventing decay, caps, applications, etc., can solve the problems of deterioration of fluid, difficult cleaning of components, and products, so as to reduce internal volume, reduce or eliminate the effect of head spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

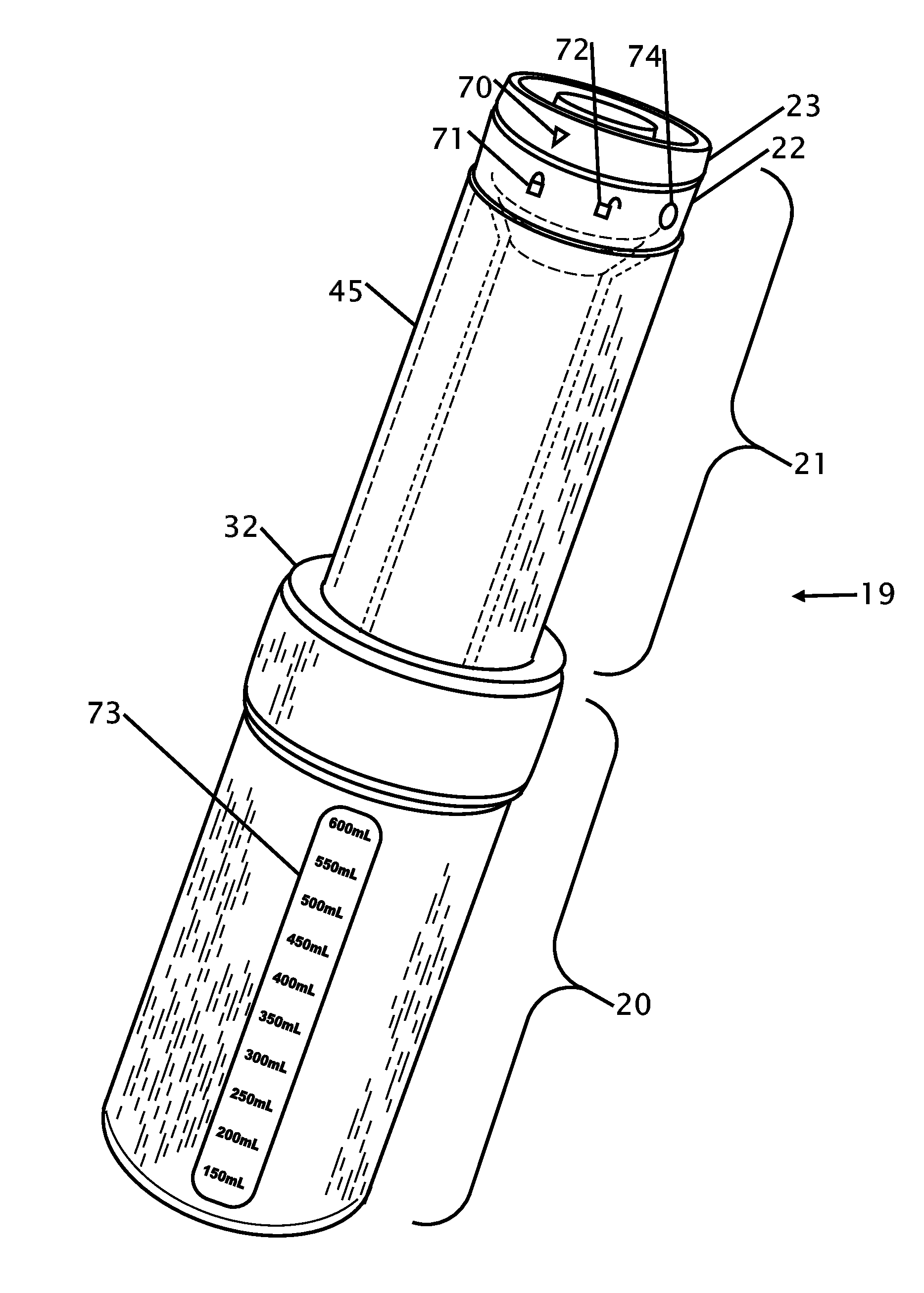

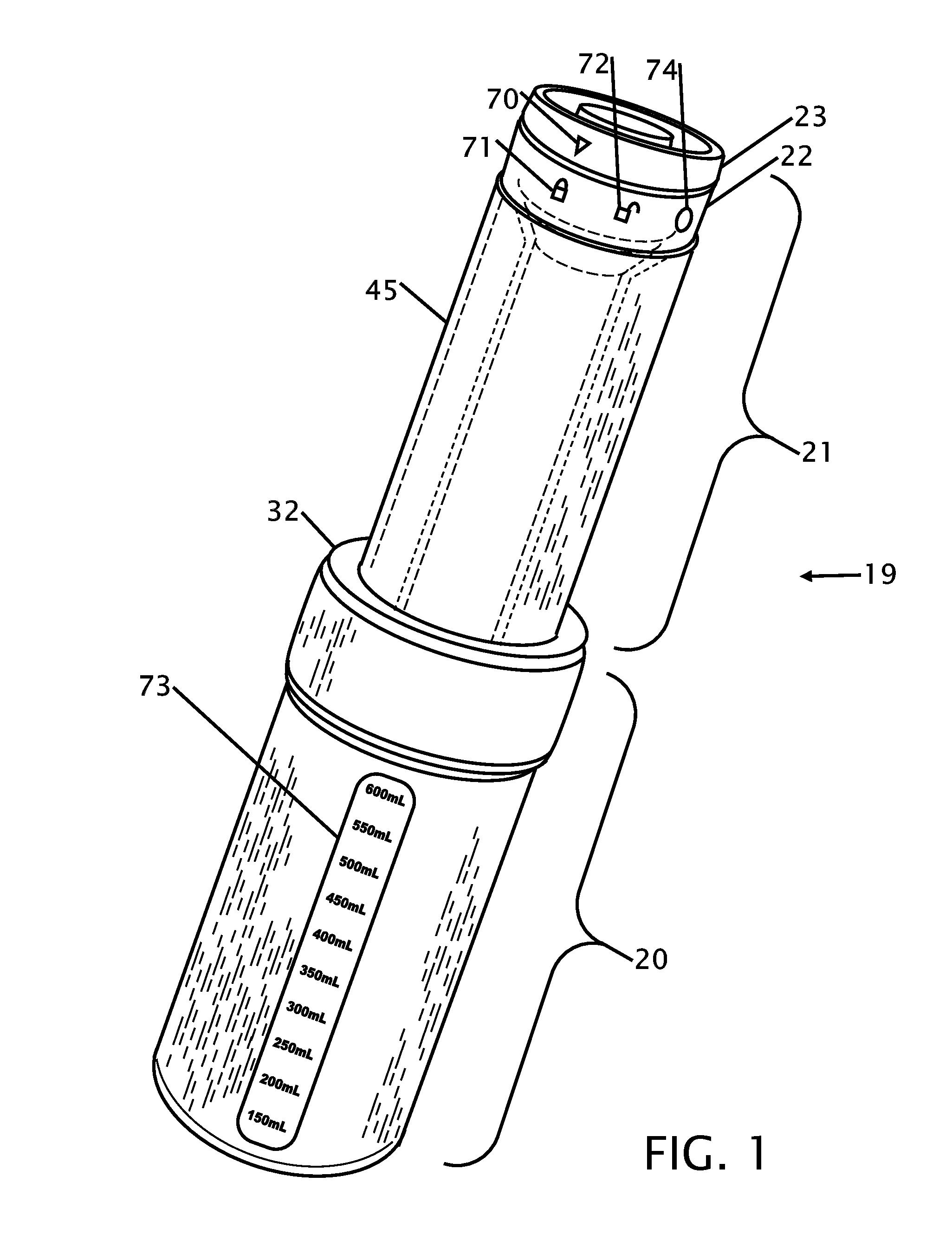

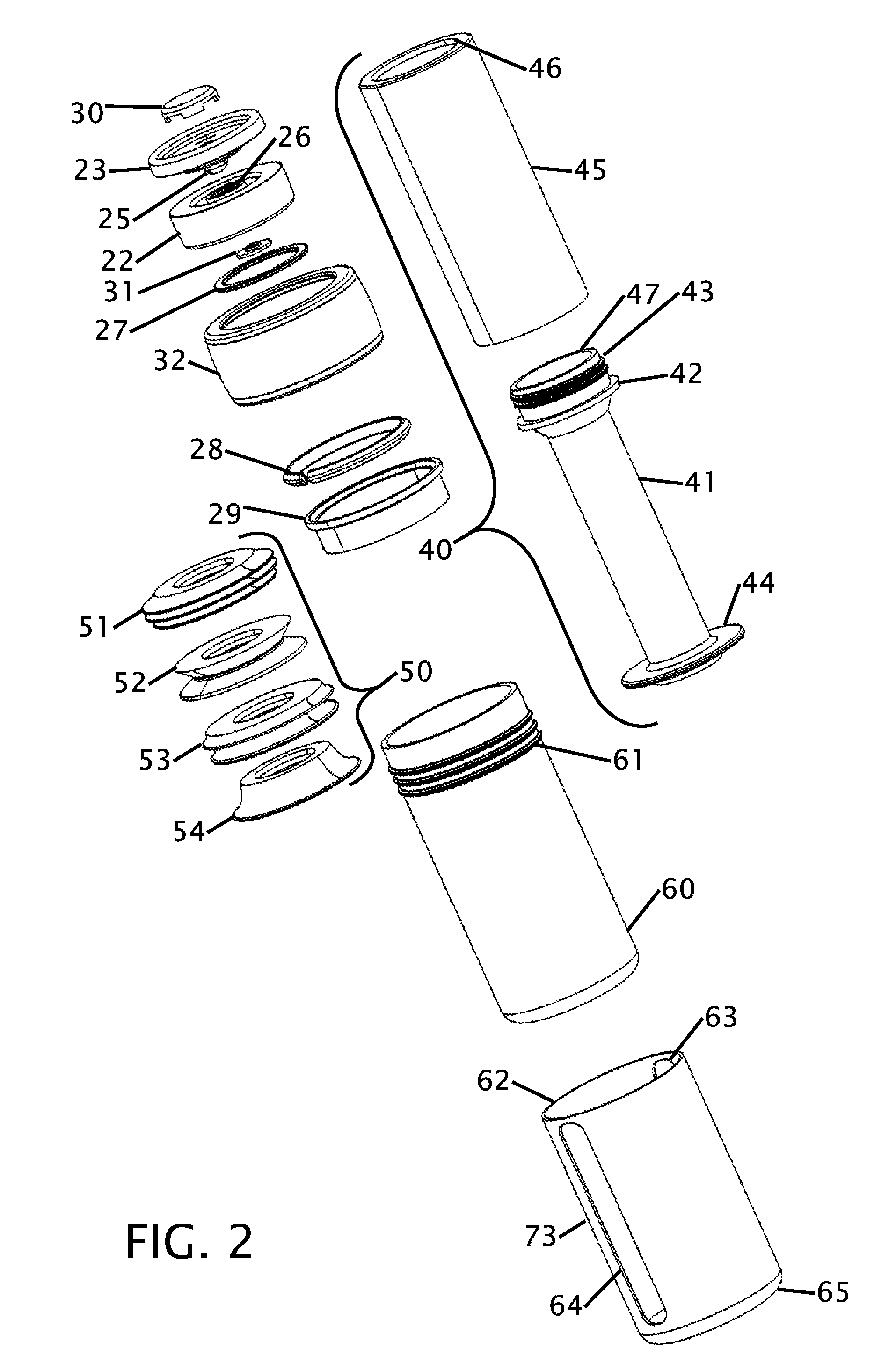

[0028]FIG. 1 shows a perspective assembled view of the adjustable volume rigid sided container 19. The container has a size and shape that is similar to a generic wine container. While the size and shape may be similar to a wine container, different sizes and shape are contemplated including more sides. The preferred embodiment has an internal volume of 750 ml, but larger or smaller internal volume containers are contemplated and provide equivalent functionality. The container 19 has a lower housing or component 20 and a top or upper component 21. The top cap has two parts 22 and 23, and it covers the pouring spout on the upper component 21. Between the lower housing component 20 and the upper component 21 a gasket seal creates a water proof seal between the two or more housing components. The upper component slides into the lower housing component 20 to reduce the internal volume of the container.

[0029]In this preferred embodiment the container has a two parts cap constructed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com