Liquid material low-temperature electric field bactericidal method

A material and liquid technology, applied in the field of low-temperature electric field sterilization of liquid materials, can solve the problems of affecting the effect of electric field sterilization and enzyme sterilization, voltage reduction, energy consumption, etc., to achieve the effect of ensuring the effect of sterilization and enzyme sterilization, reducing current and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] Taking fruit and vegetable juice as an example, a specific embodiment of the low-temperature electric field sterilization method for liquid materials of the present invention is listed as follows:

[0043] First process fruits and vegetables through crushing, pressing, filtering, juice extraction and other processes to obtain fresh fruit and vegetable juice, and then process them according to the following steps:

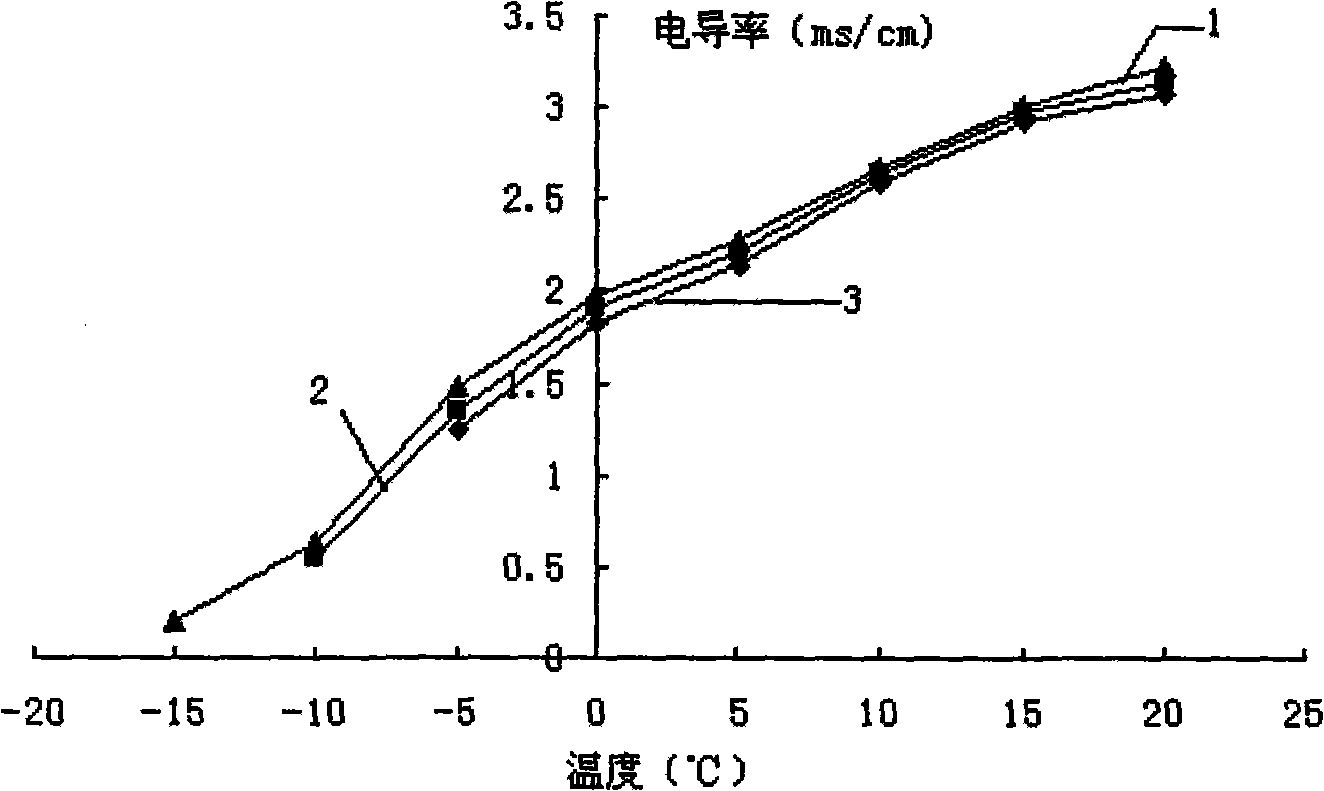

[0044] ①Cool the fruit and vegetable juice to below 0°C for freezing and concentration, so that the water in the fruit and vegetable juice forms ice crystals, and then separate the ice crystals from the concentrated liquid to obtain non-thermal fruit and vegetable concentrated juice. This technology can usually make fruit and vegetable juice The concentration ranges from 35% to 40% (w / w). This means that the fruit and vegetable juice with an original concentration of 8% has been excluded from more than 3 / 4 of its moisture, and its volume has been reduced to 1...

Embodiment 1

[0054] Embodiment 1: non-thermal solid orange juice (concentration is in soluble solids concentration meter)

[0055] (1) Select fresh oranges, wash them, drain them, cut them in half, squeeze the juice, and take the filtered orange juice.

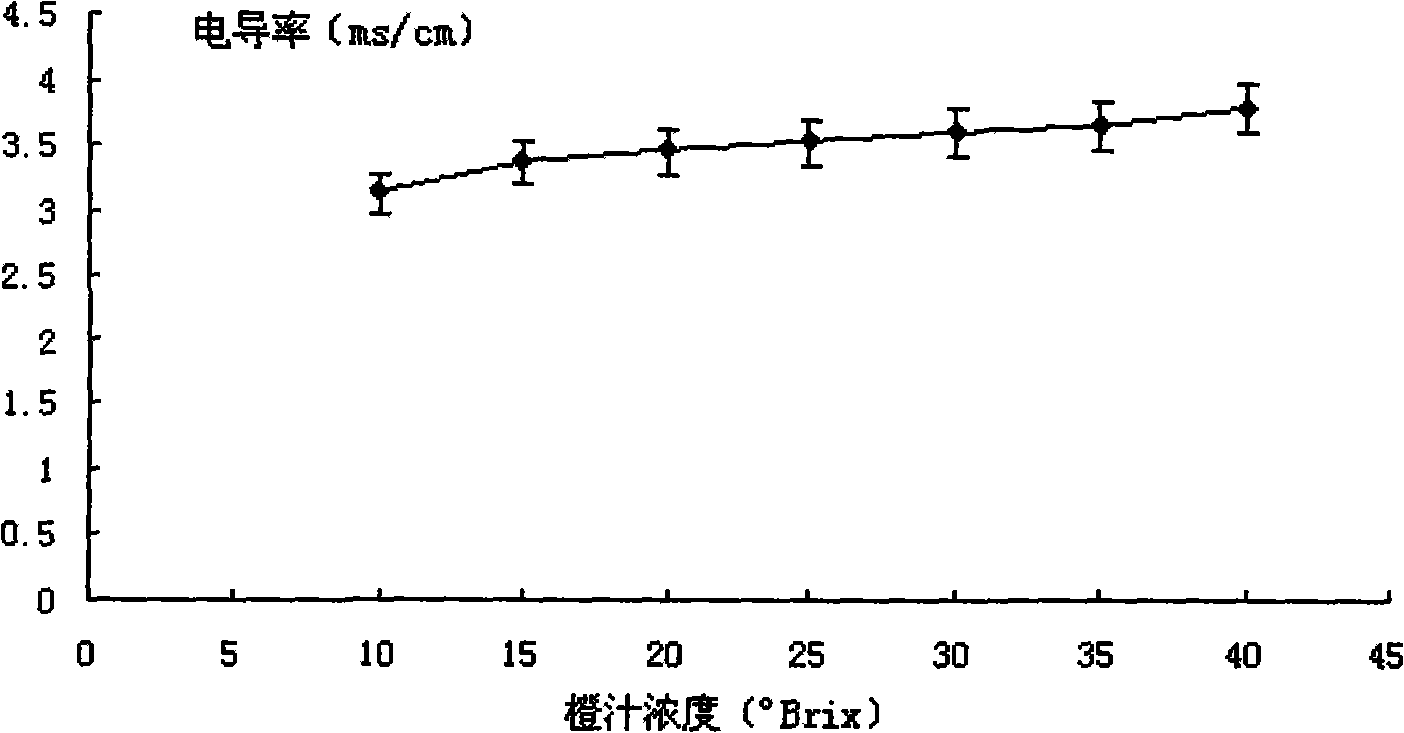

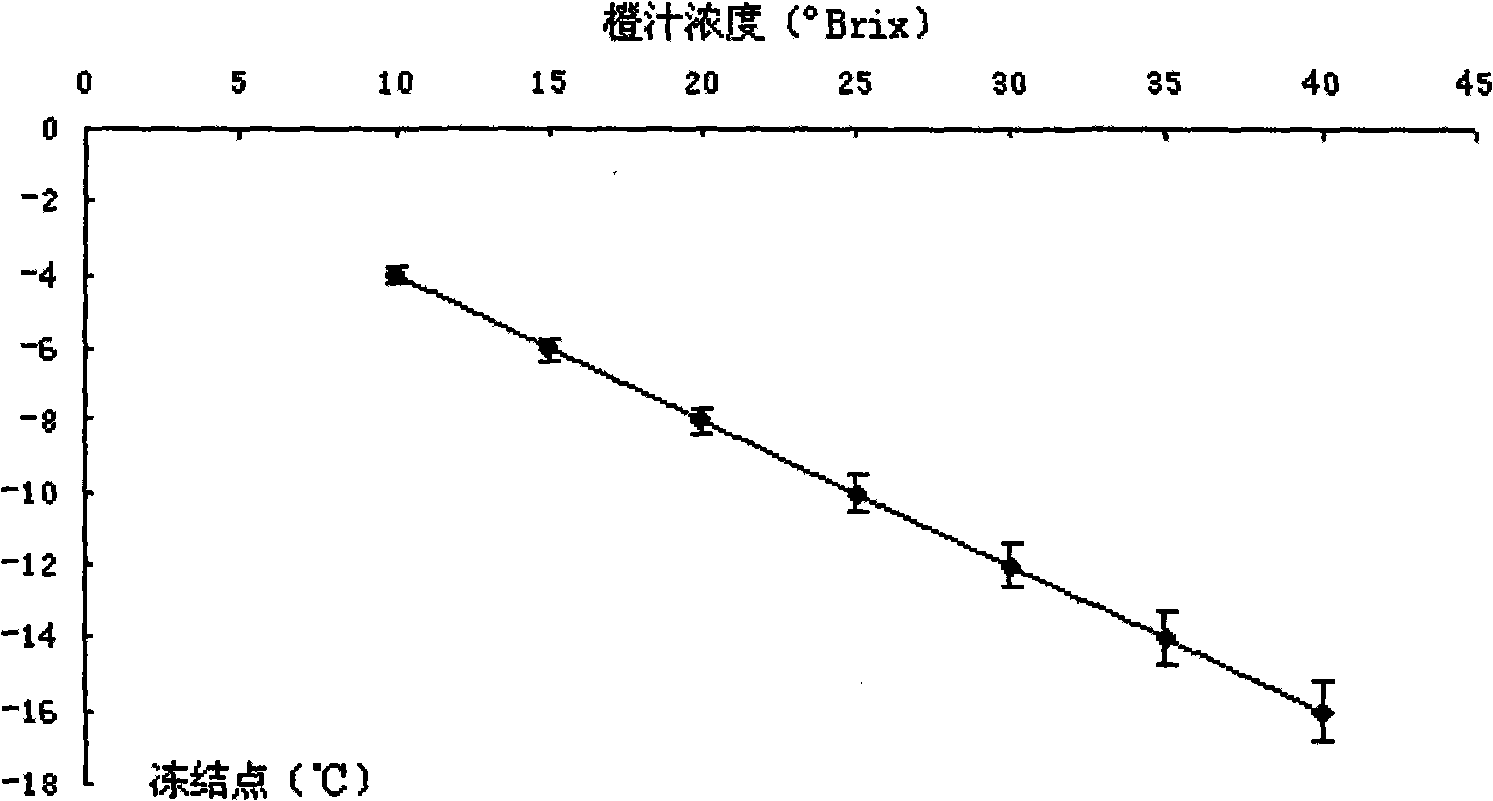

[0056] (2) The orange juice with an initial concentration of 12°Brix was freeze-concentrated at -1°C to -6°C to become a freeze-concentrated orange juice with a concentration of 36°Brix, and the concentration factor was 3.

[0057] (3) It is 1000V / cm that above-mentioned freeze-concentrated orange juice flows through electric field strength at low temperature, frequency 20MHz, the high-frequency electric field that processing time is 12s, obtains cold sterilization concentrated orange juice after carrying out sterilization; Or flow through electric field strength is 10kv / cm, A high-voltage pulsed electric field with a pulse number of 400 and a pulse width of 17 μs was used to obtain cold-sterilized concentrated orange juice after steriliza...

Embodiment 2

[0060] Embodiment 2: non-thermal power solid carrot juice (concentration is in soluble solids concentration meter)

[0061](1) Choose fresh carrots, wash, drain, peel, beat, filter, and take the filtered carrot juice

[0062] (2) Carrot juice with an initial concentration of 7°Brix was freeze-concentrated at -3°C to -6°C to become freeze-concentrated carrot juice with a concentration of 33°%, and the concentration factor was 4.7.

[0063] (3) It is 2000V / cm that above-mentioned freeze-concentrated carrot juice flows through electric field intensity, and frequency 20MHz, the high-frequency electric field that processing time is 12s, after carrying out sterilization, obtain cold sterilization concentrated carrot juice; Or flow through electric field intensity and be 20kV / cm, A high-voltage pulse electric field with a pulse number of 400 and a pulse width of 17 μs was used for sterilization to obtain cold-sterilized concentrated carrot juice.

[0064] (4) the concentration that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com