Fuel system of heavy-duty diesel engine

A technology for heavy-duty diesel engines and fuel systems, which is used in charging systems, mechanical equipment, engine components, etc., to solve problems such as the inability to automatically discharge fuel gas absorbed by negative pressure, affecting the filtration efficiency of fuel filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

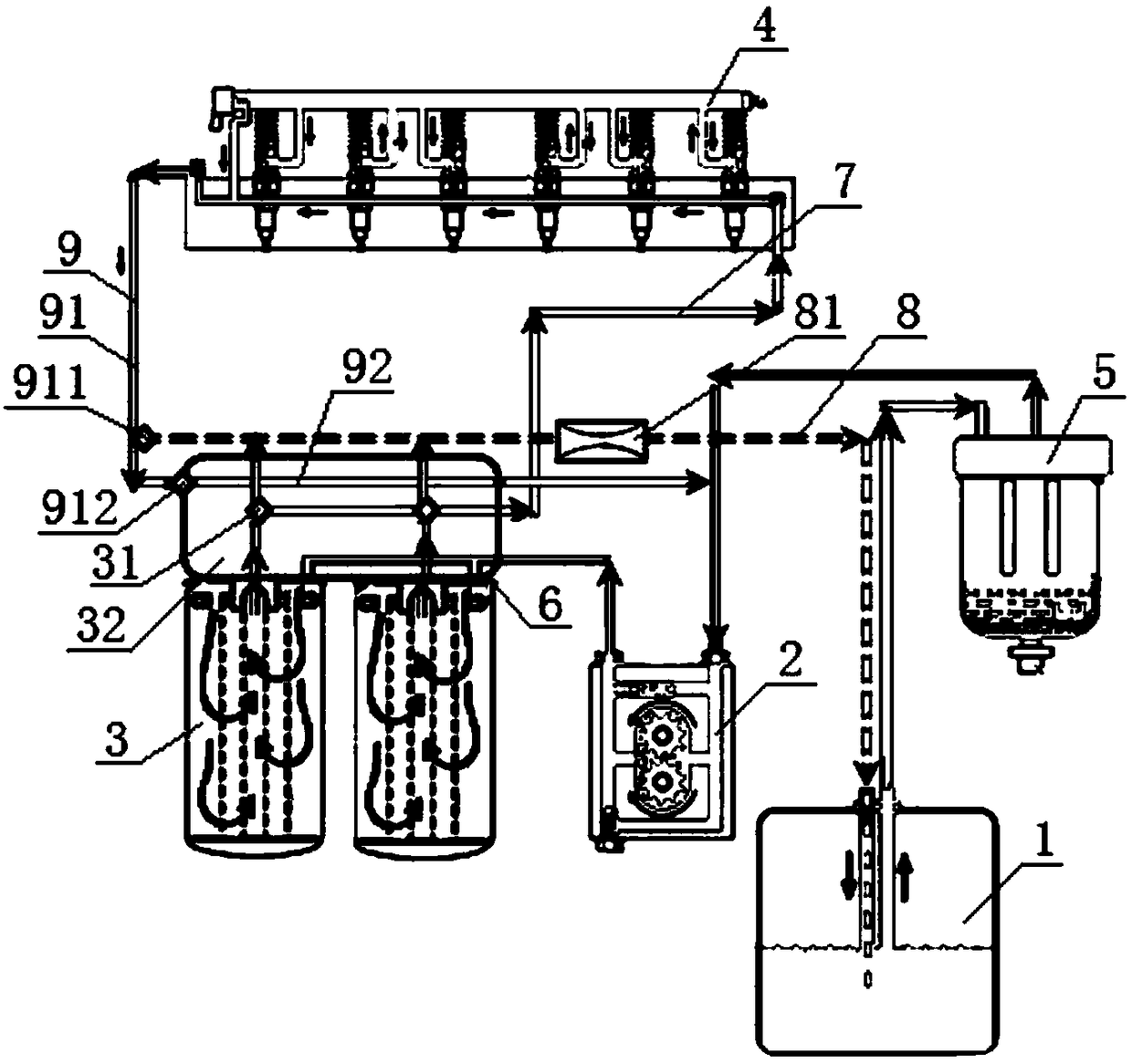

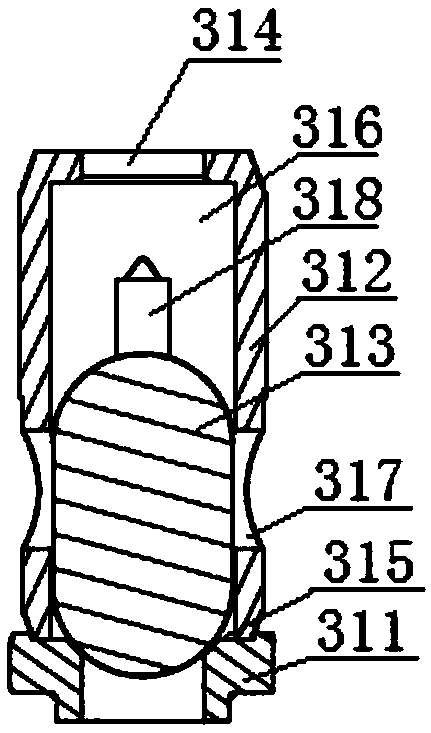

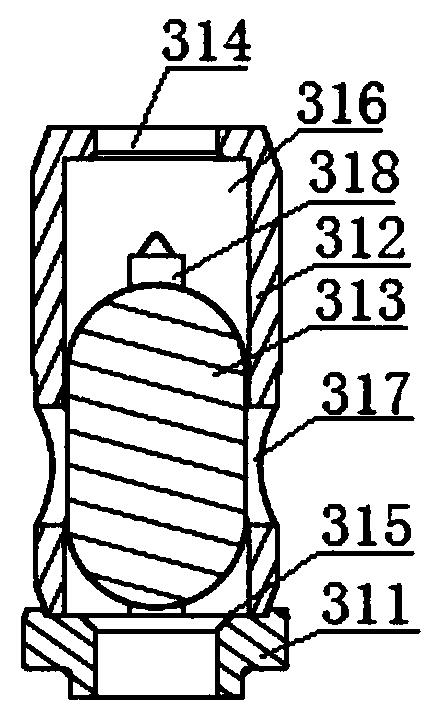

[0049] see Figure 1 to Figure 4 , a fuel system for a heavy-duty diesel engine, comprising a fuel tank 1, a low-pressure fuel delivery pump 2, a fuel filter 3, a fuel injector assembly 4, and a pre-filter 5, the fuel tank 1 and the pre-filter 5 are fixedly connected to the vehicle frame, and the The low-pressure fuel delivery pump 2 and the fuel filter 3 are fixedly connected to the engine, the fuel injector assembly 4 is located inside the rocker chamber, the fuel filter 3 is a double element filter, and the base of the fuel filter 3 32 is provided with an automatic exhaust three-way valve 31, the automatic exhaust three-way valve 31 is set near the oil outlet of the filter element, including a valve seat 311, a valve body 312, a valve ball 313, the valve seat 311, valve body 312 Both are hollow structures with openings at both ends. The exhaust port 314 of the valve body 312 communicates with the oil inlet port of the fuel tank 1 through the exhaust pipeline 8, and the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com