PVC stripping roller closed-loop circulating filtering cooling device

A closed-circuit circulation and cooling device technology, applied in the fields of filtration and separation, fixed filter element filters, separation methods, etc., can solve the problems of large losses, impact on production, human and material resources investment, etc., and achieve long maintenance cycles, sufficient cooling water, Significant power savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

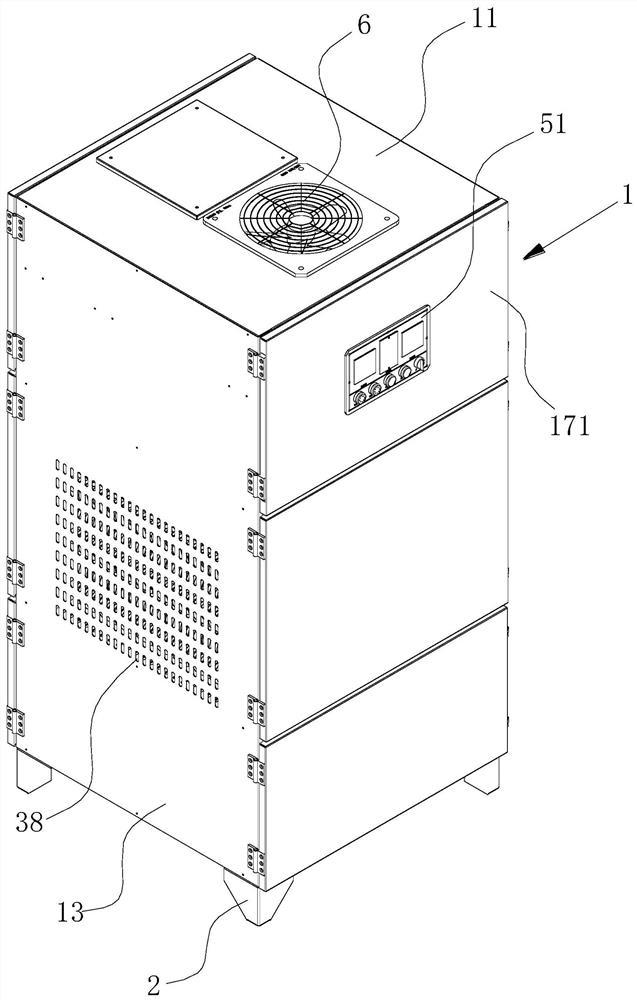

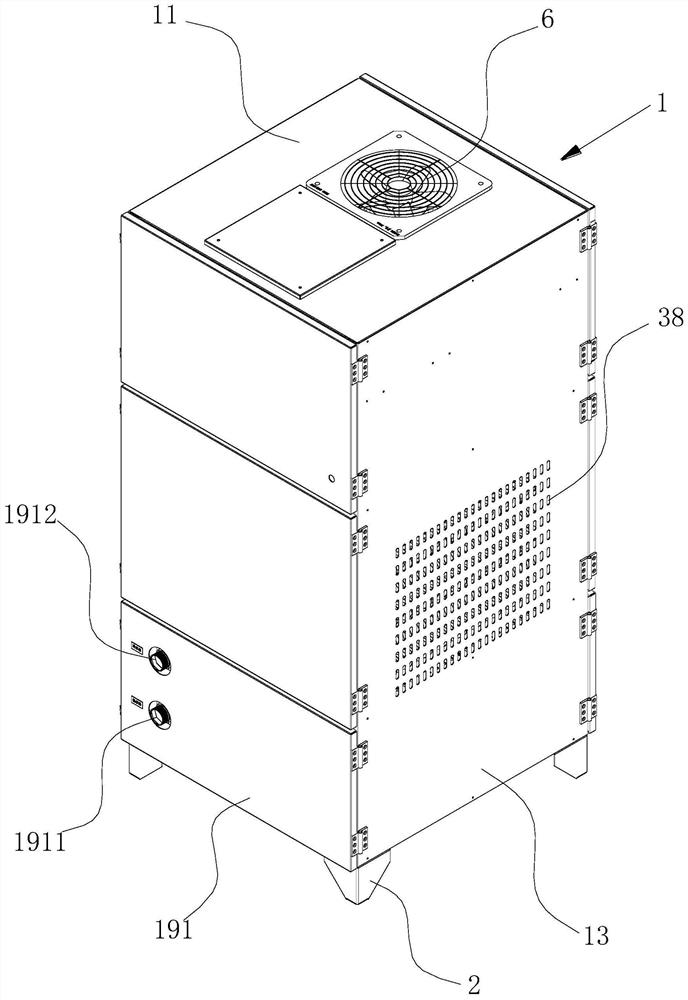

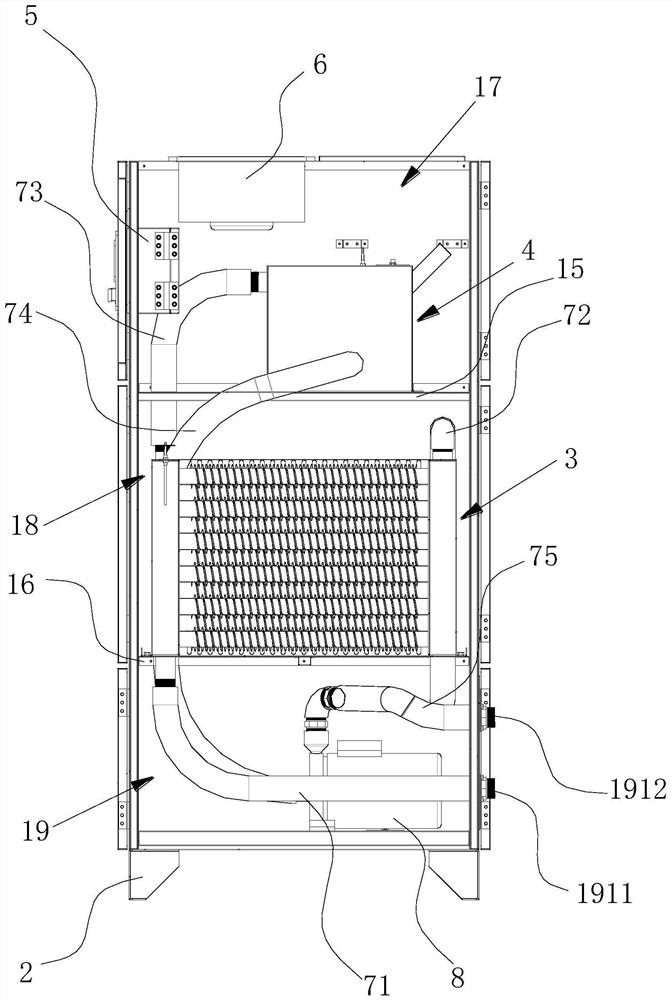

[0033] see Figure 1-Figure 9 , a PVC peeling roller closed-circuit circulation filtration cooling device is characterized in that: it includes a vertically arranged rectangular cabinet body 1, and the cabinet body 1 includes an upper cabinet board 11, a lower cabinet board 12, a left cabinet board 13 and a right cabinet board 14, Inside the cabinet body 1, there are upper and lower boards 15 and lower boards 16 arranged at intervals and are horizontal. The upper boards 15 and the lower boards 16 are all orifice boards. The upper boards 15 and the lower boards 16 divide the cabinet body 1 into an upper chamber. 17. The middle chamber 18 and the lower chamber 19, the cabinet body 1 corresponds to the upper chamber 17, the middle chamber 18 and the lower chamber 19 are respectively provided with independent front cabinet doors and rear cabinet doors;

[0034] The lower chamber 19 is provided with a circulating pump 8, and the rear cabinet door 191 of the lower chamber 19 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com