Thermostatic trap

A steam trap and constant temperature technology, applied in steam traps, mechanical equipment, etc., can solve the problems of huge steam pressure, heavy feeling of adjustment, and increase the difficulty of precise adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

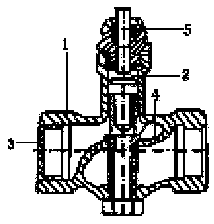

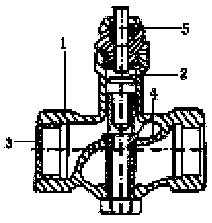

[0008] A thermostatic steam trap, the steam trap includes a valve body 1, a temperature sensing element 2, a filter screen 3, an elastic liner 4, and a telescopic assembly 5, the valve body 1 includes a water inlet and a water outlet, the The elastic liner 4 is set in the valve main body 1, the filter screen 3 is set at the water inlet and the water outlet, the telescopic assembly 5 is set on the upper part of the valve main body 1, and the telescopic assembly 5 is connected with a temperature sensor Components 2, the telescopic assembly 5 is in contact with the elastic liner 4, the elastic liner 4 is a rubber elastic liner, and the telescopic assembly 5 is a piston assembly.

[0009] The above embodiments are only used to illustrate the present invention rather than limit the technical scheme described in the present invention; therefore, although the present description has described the present invention in detail with reference to the above-mentioned embodiments, the ordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com