Automatic-exhausting infusion needle seat

An automatic exhaust and self-exhaust technology, which is applied to the introduction of devices into the body, hypodermic injection devices, etc., can solve the problems of high cost, difficult air discharge, complex structure of the exhaust device, etc., and achieve the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

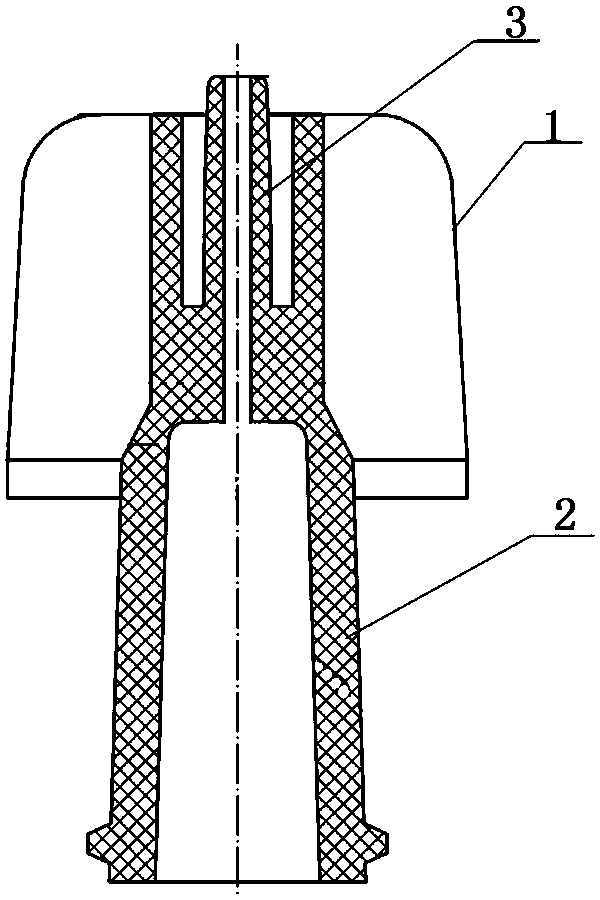

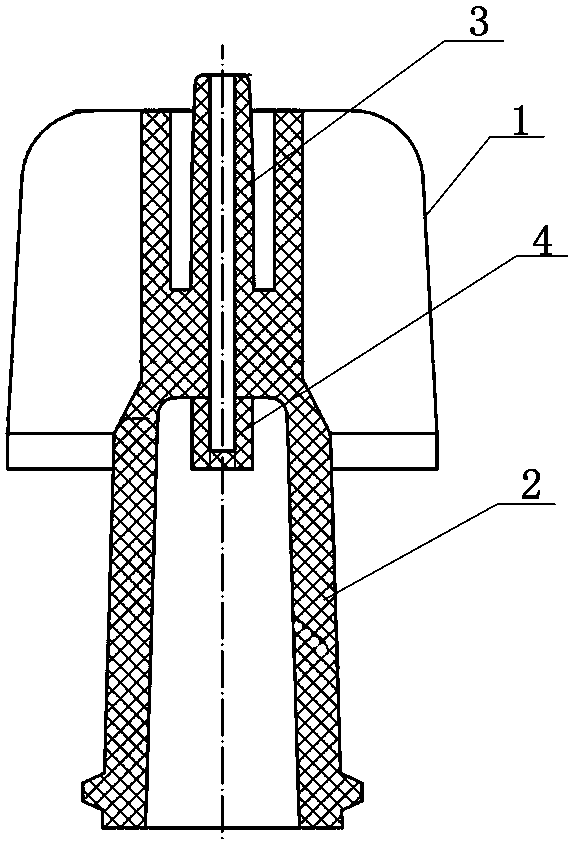

[0014] like figure 2 As shown, a self-venting infusion needle holder includes an infusion outer tube 2, an infusion inner tube 3 is set in the upper cavity of the infusion outer tube 2, the upper end of the infusion inner tube 3 protrudes along the infusion outer tube 2, and the infusion The protruding end of the inner tube 3 is connected to the needle, the lower end of the infusion inner tube 3 is fixedly connected to the infusion outer tube 2, and the lower end of the infusion inner tube 3 is connected to the self-venting assembly 4, which consists of a side wall and a bottom end , the inner cavity of the self-exhaust assembly 4 communicates with the inner cavity of the infusion tube 3, the lower section of the side wall of the self-exhaust assembly 4 has a through hole, and a plurality of through holes are arranged along its circumferential direction, and the side wall of the self-exhaust assembly 4 There is a gap between the wall and the inner wall of the infusion outer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com