Method and device for achieving low emission of heavy-duty diesel engine through controlling exhaust temperature

A heavy-duty diesel engine, low-emission technology, applied in the direction of electronic control and electrical control of exhaust devices and exhaust gas treatment devices, can solve the problems of thermal aging of catalysts, reduce fuel economy advantages of diesel engines, and high costs, and achieve long-term satisfaction. The effect of distance work and ultra-low standby power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

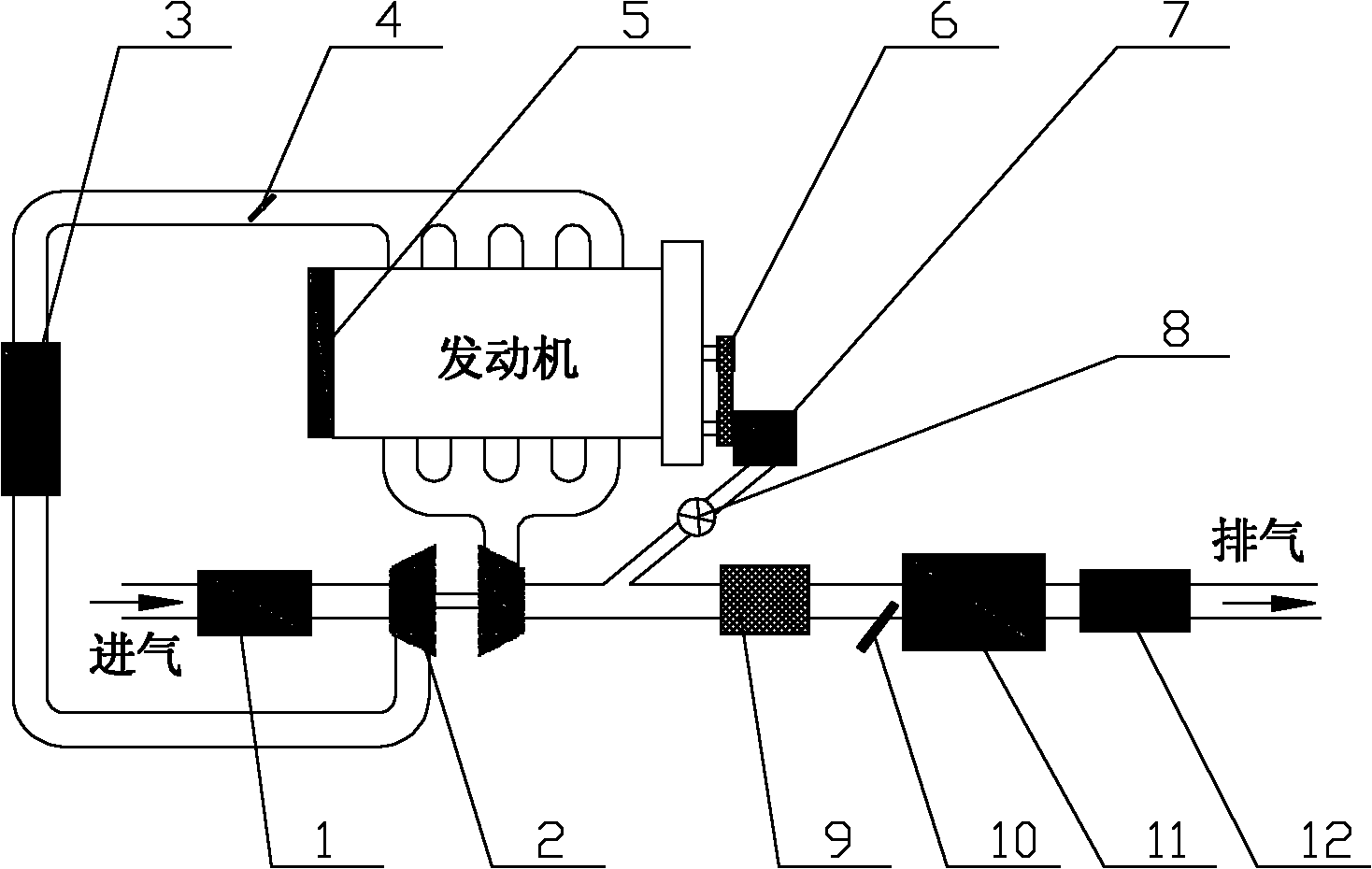

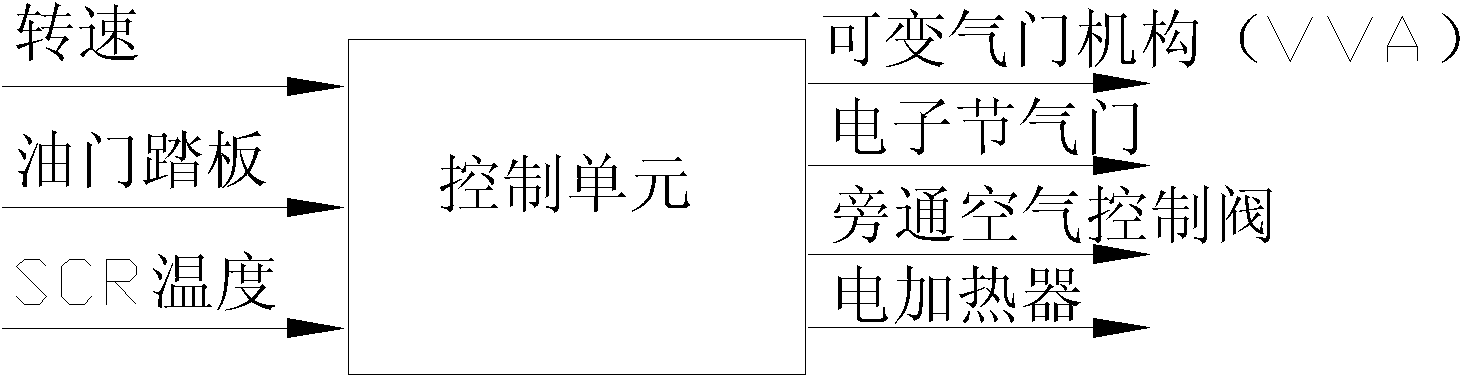

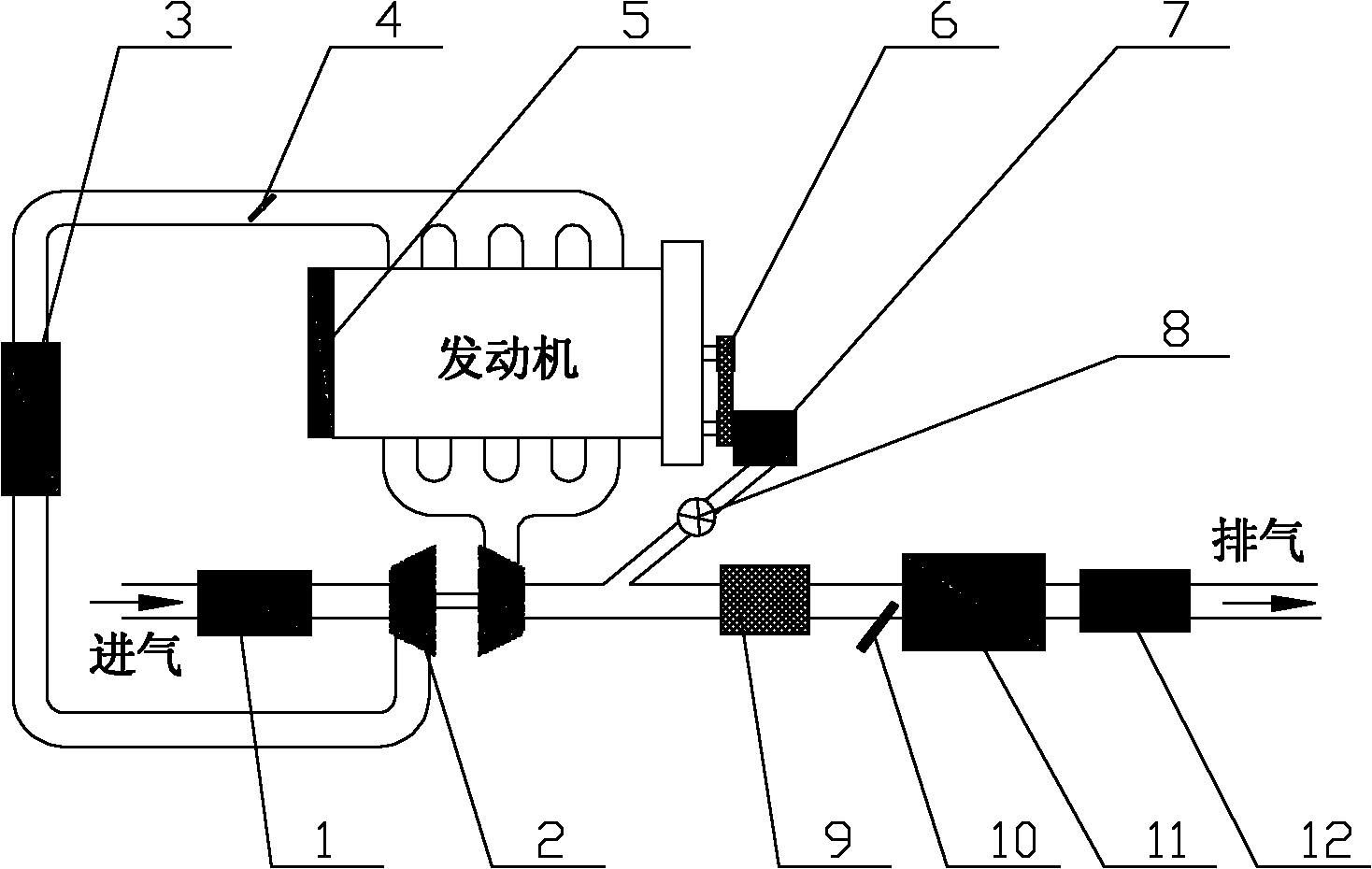

[0031] If the exhaust temperature before the SCR can be controlled in this high-efficiency range in the full range of working conditions, the conversion efficiency of the SCR can be greatly improved; at this time, the soot ( particulate) emissions, thereby reducing the requirement for particulate aftertreatment. Therefore, by adopting the method of exhaust temperature control, it is possible to meet the Euro 6 emission requirements under the condition of using SCR and DOC post-processors.

[0032] The purpose of the present invention is to overcome the deficiencies in the prior art, and propose a method to improve the conversion efficiency of SCR to NOx by controlling the exhaust temperature of heavy-duty diesel engines, so that NOx emissions can meet the Euro 6 emission regulations without using EGR technology; In-cylinder fuel injection pressure and combustion optimization reduce particle emissions, and make particles meet Euro 6 requirements under the condition of using DOC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com