Active oil-gas separator

An oil-gas separator and active technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of reduced performance and reliability of the whole machine, low efficiency of oil-gas separation, and inability to meet the closed crankcase ventilation system. , to achieve the effect of convenient machine layout, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

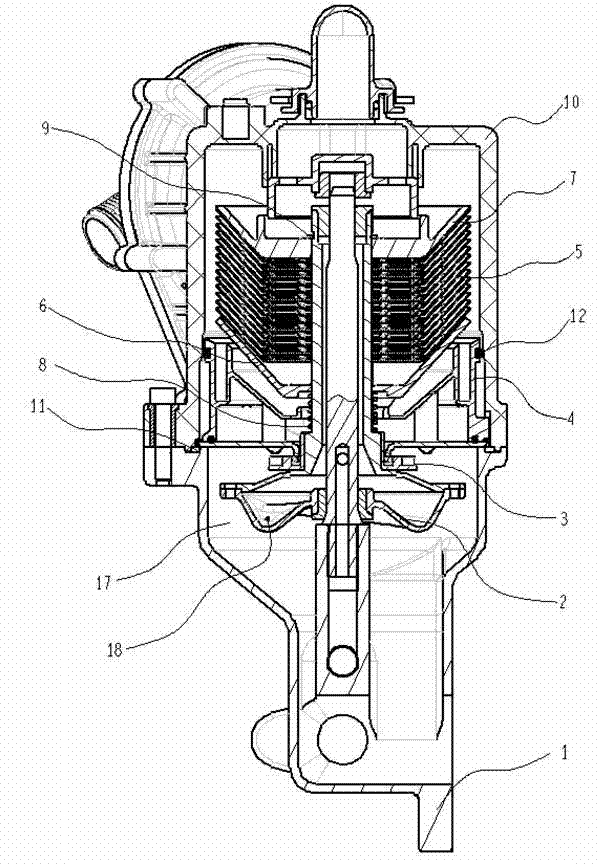

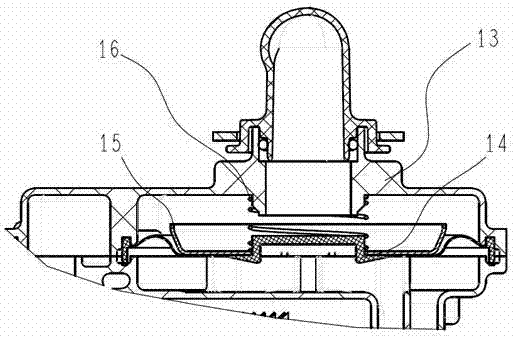

[0010] The high-pressure lubricating oil enters the drive shaft assembly 2 through the base assembly 1, and is sprayed out through two oil injection holes 18 with a diameter of 1.8 mm on the drive shaft assembly 2 and which are symmetrical along the rotation center. The force couple formed by engine oil injection drives the drive shaft to rotate around the center; the laminations 5, the lamination upper body 7 and the lamination lower body 6 are fixed on the drive shaft assembly 2 through the limit spring 8 and the retaining spring 9, and follow the drive shaft assembly 2. Perform high-speed rotation; at this time, the crankcase exhaust gas entering the oil-gas separator through the upper shell assembly 10 passes through the high-speed rotating laminations. The centrifugal force generated by the rotation will cause the liquid oil droplets and particles in the exhaust gas of the crankcase to fly away from the laminations and hit the wall of the shell assembly 10, thereby complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com