Vehicle evaporative emission operation loss VOCs emission factor measurement method

A technology of emission factor and operation loss, applied in the direction of measuring devices, instruments, etc., can solve the problems of high operation and maintenance costs, difficulty in obtaining emission factors of VOCs evaporative emission operation loss, and failure to reflect vehicle activity status, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

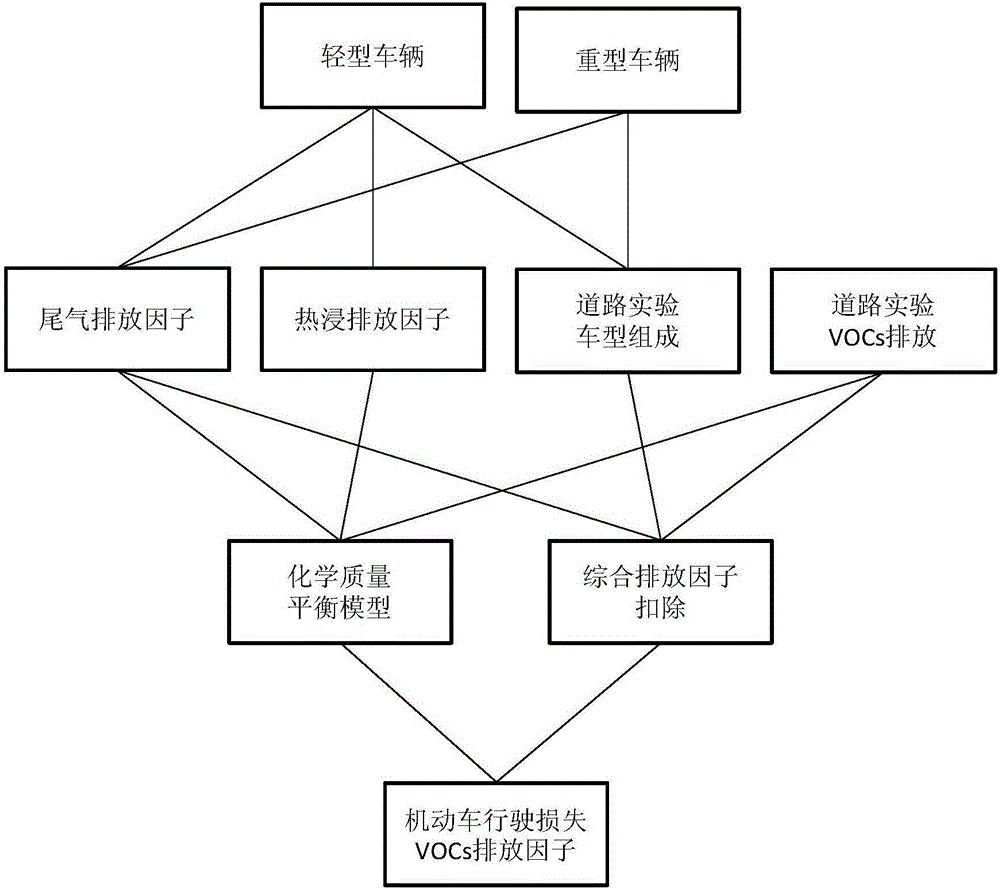

[0014] like figure 1 As shown, the present invention has two parallel technical paths, and the technical solutions adopted respectively are as follows:

[0015] Technical approach 1: According to the quality of environmental VOCs, traffic flow characteristics, composition ratio of light-duty gasoline vehicles and heavy-duty diesel vehicles measured by multiple road experiments, analyze the total VOCs emission factors of light-duty gasoline vehicles and heavy-duty diesel vehicles under actual road conditions, and The exhaust emission factor measured in the laboratory is deducted to obtain the VOCs emission factor of motor vehicle operation losses under actual road conditions, and the method includes the following steps.

[0016] Step 1: According to the current vehicle VOCs emission standard test method in the region, select representative light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com