Device and method for measuring key-phase signal of steam turbine generator unit

A steam turbine generator set and key phase signal technology, which is applied to measuring devices, electrical devices, safety devices, etc., can solve the problems of easily damaged reflective strips, affecting the accuracy of key phase signals, and inability to obtain accurate signals. Complicated steps and required man-hours, realizing the effect of real-time vibration monitoring and continuous and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

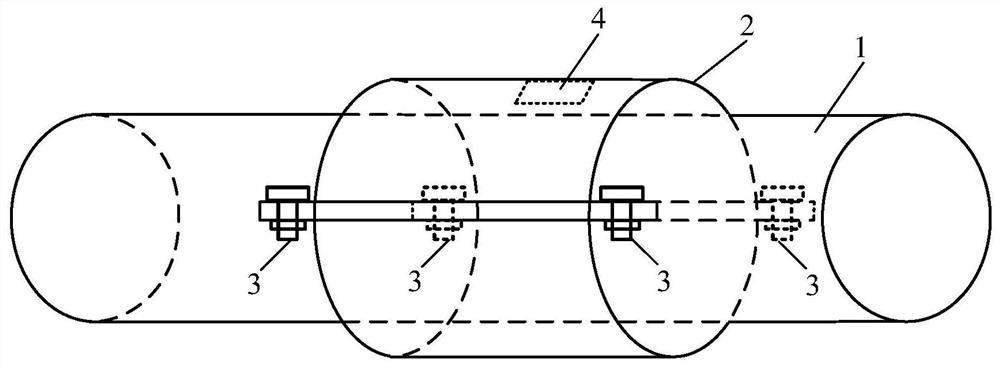

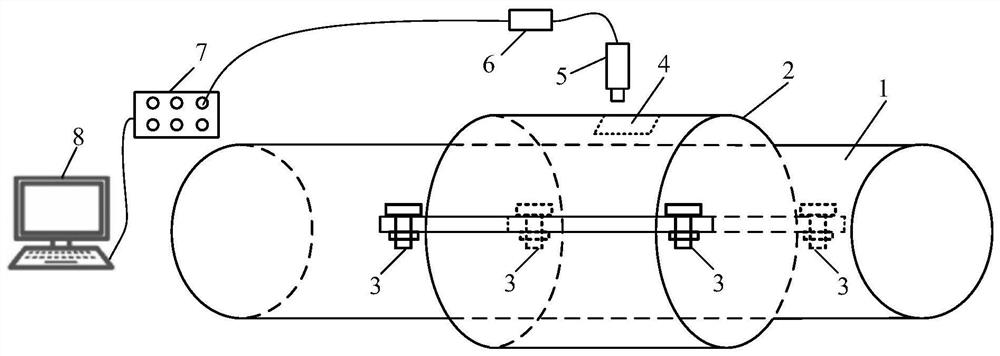

Embodiment 1

[0029] Example 1: Such as figure 2 As shown, a steam turbine generator set key signal measuring device and a measurement method comprising a slotting hoop 2, a TV turntable phase sensor 5, a fronter 6, and a data acquisition device 7. First installed on the rotor 1 figure 1 The slotted hoop 2 is shown, the slotting hoop 2 is opened with a measuring groove 4, and the eddy current key sensor 5 is positively pair of measuring grooves 4, and is fixed to the sensor holder, and then the eddy current key phase sensor 5 is The front member 6 is connected, and the output of the fronter 6 is connected to the data acquisition device 7, and the data acquisition device is connected to the computer 8. When the turbine generator sets, the rotor 1 rotates at high speed, and whenever the measuring groove 4 passes the eddy current key sensor 5, it will produce Figure 4 The pulse signal shown, that is, a key signal. The device can realize the long-term and stable measurement of the key signal of the...

Embodiment 2

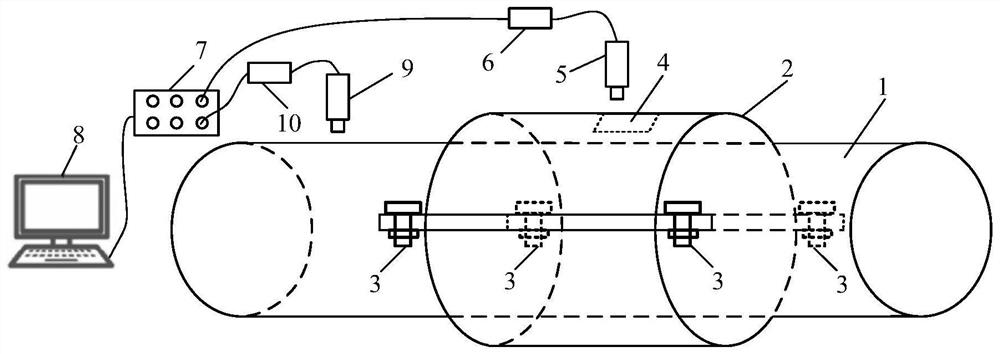

[0033] Example 2: Such as image 3 As shown, a steam turbine generator set key signal and a vibration phase measuring device and a measurement method include a slotting hoop 2, a vortex stream key sensor 5, a vortex stream key sensor front, a vibration sensor 9, vibration Sensor front device 10, and data acquisition device 7. First installed on the rotor 1 figure 1 The slotted hoop 2 is shown, the slotting hugging surface is opened with a measuring groove 4, and the vortex stream key sensor 5 is positively to the measuring groove 4, and is fixed to the sensor holder, and then the eddy current key sensor 5 and the front The device 6 is connected. The vibration sensor 10 is mounted in the radial direction of the rotor 1 and is fixed to the sensor holder, and then the vibration sensor 9 is connected to the fronter 10. Connect the output of the front member 6 and the fronter 10 to the data acquisition device 7, the data acquisition device is connected to the computer 8. The number of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The peak | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com