Continuous casting two cold closed chamber casting blank surface temperature field measuring device

A surface temperature and measuring device technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, instruments, etc., to achieve the effect of strong resistance to high temperature environment and prevention of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

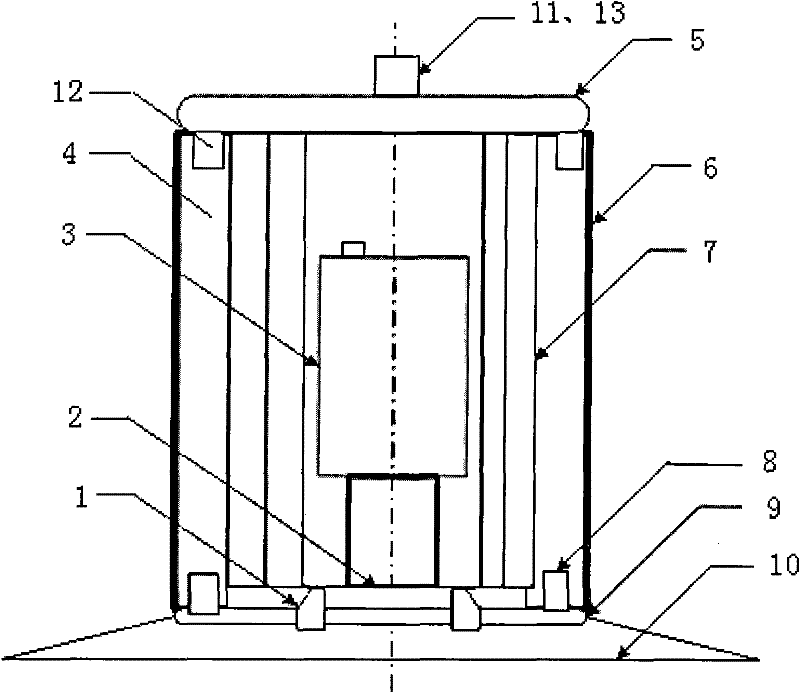

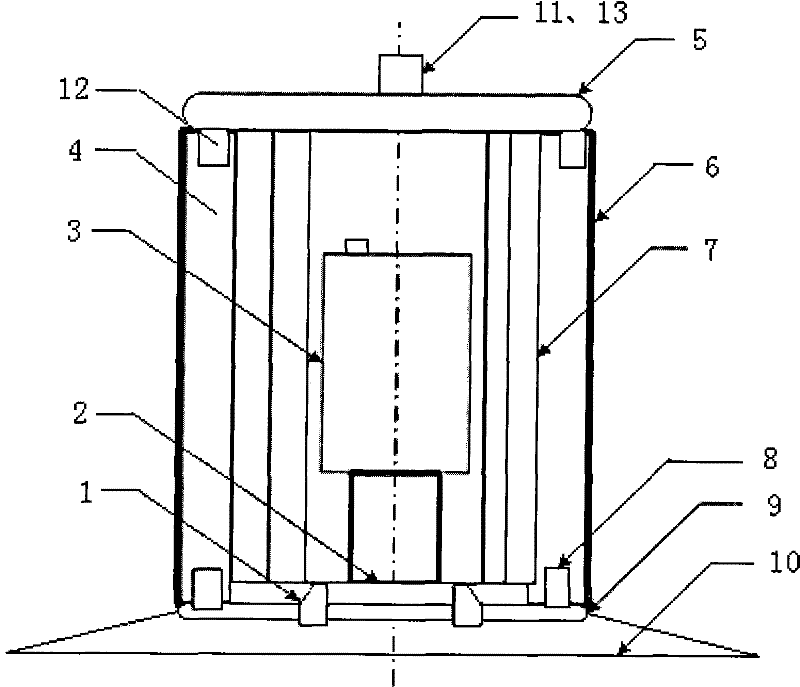

[0019] see figure 1 , as can be seen from the figure, the device for measuring the surface temperature field of the slab in the continuous casting secondary cooling airtight chamber of the present invention mainly includes a cleaning mechanism 1, quartz glass 2, an infrared array CCD camera 3, an inlet gas splitter 5, and a cooling jacket 6 , heat insulation protective sleeve 7, cooling gas outlet 8, outlet airflow separator 9, guiding mechanism 10.

[0020]The infrared array CCD camera 3 is arranged in the heat insulation protection casing 7, and the quartz glass 2 is arranged in the front end of the heat insulation protection casing 7. The function of the quartz glass is to prevent the polluting medium from entering the heat insulation protection casing and causing damage to the CCD camera. Due to the high temperature of the cast strand, quartz glass should be resistant to high temperatures. The cooling jacket 6 is sleeved on the outside of the heat-insulation protection sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com