Force detector and detection method for stress generated by defferent temp of long rail

A force measuring device, temperature change technology, applied in transportation and packaging, railway vehicle shape measuring device, vehicle route interaction equipment, etc., can solve the problems of rough data, inconvenient operation, unable to obtain the continuous change process of temperature force, etc. achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

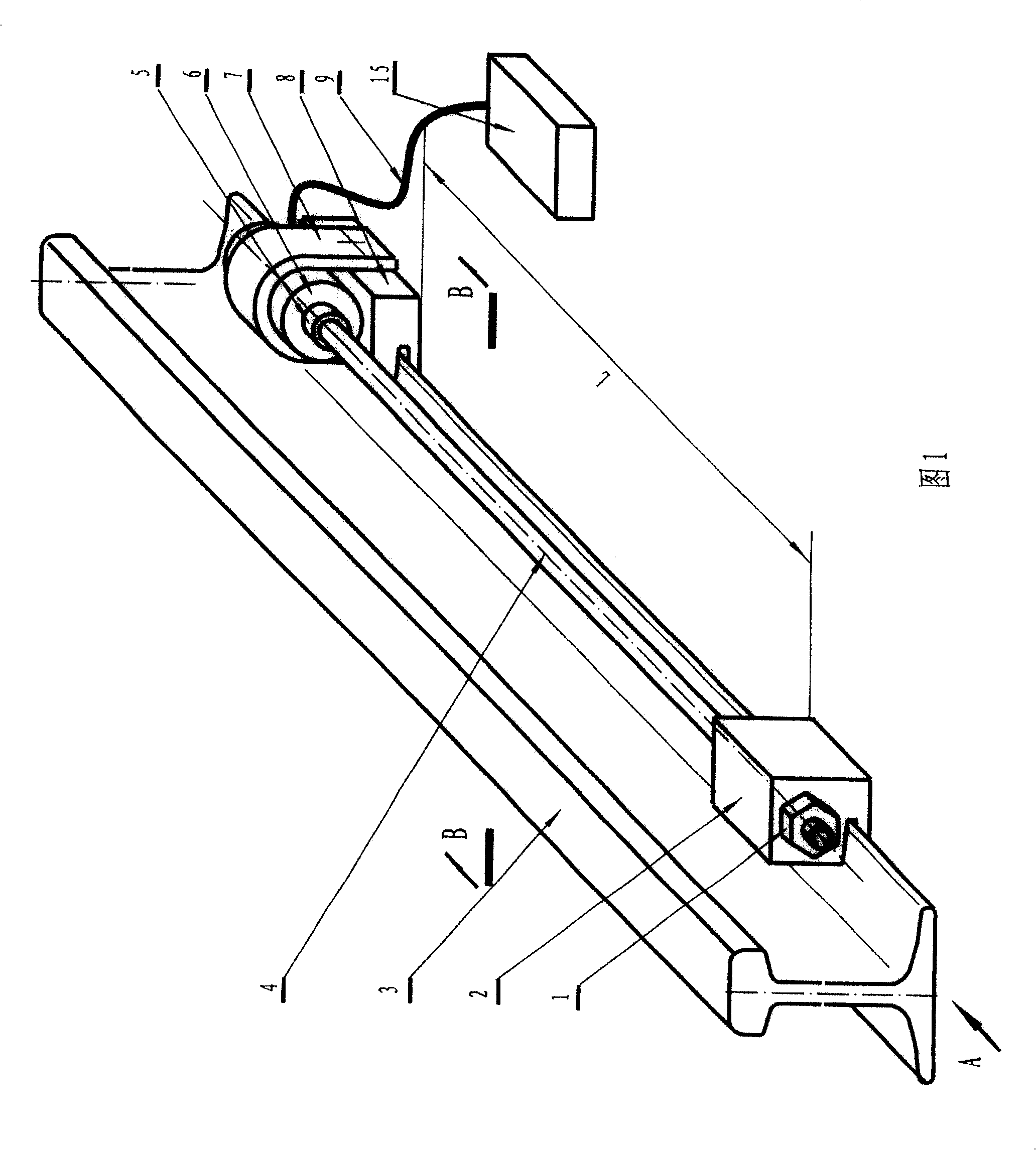

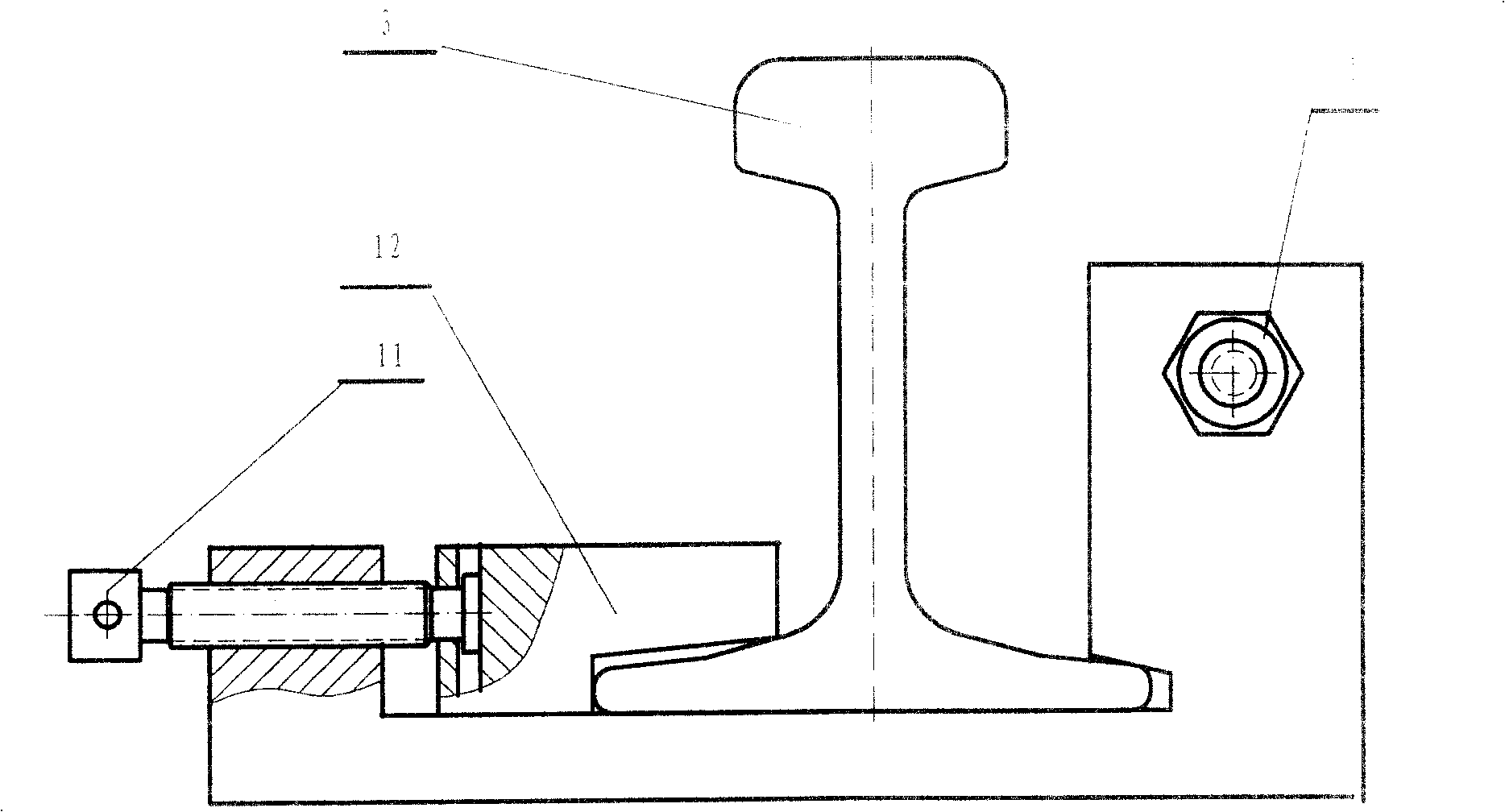

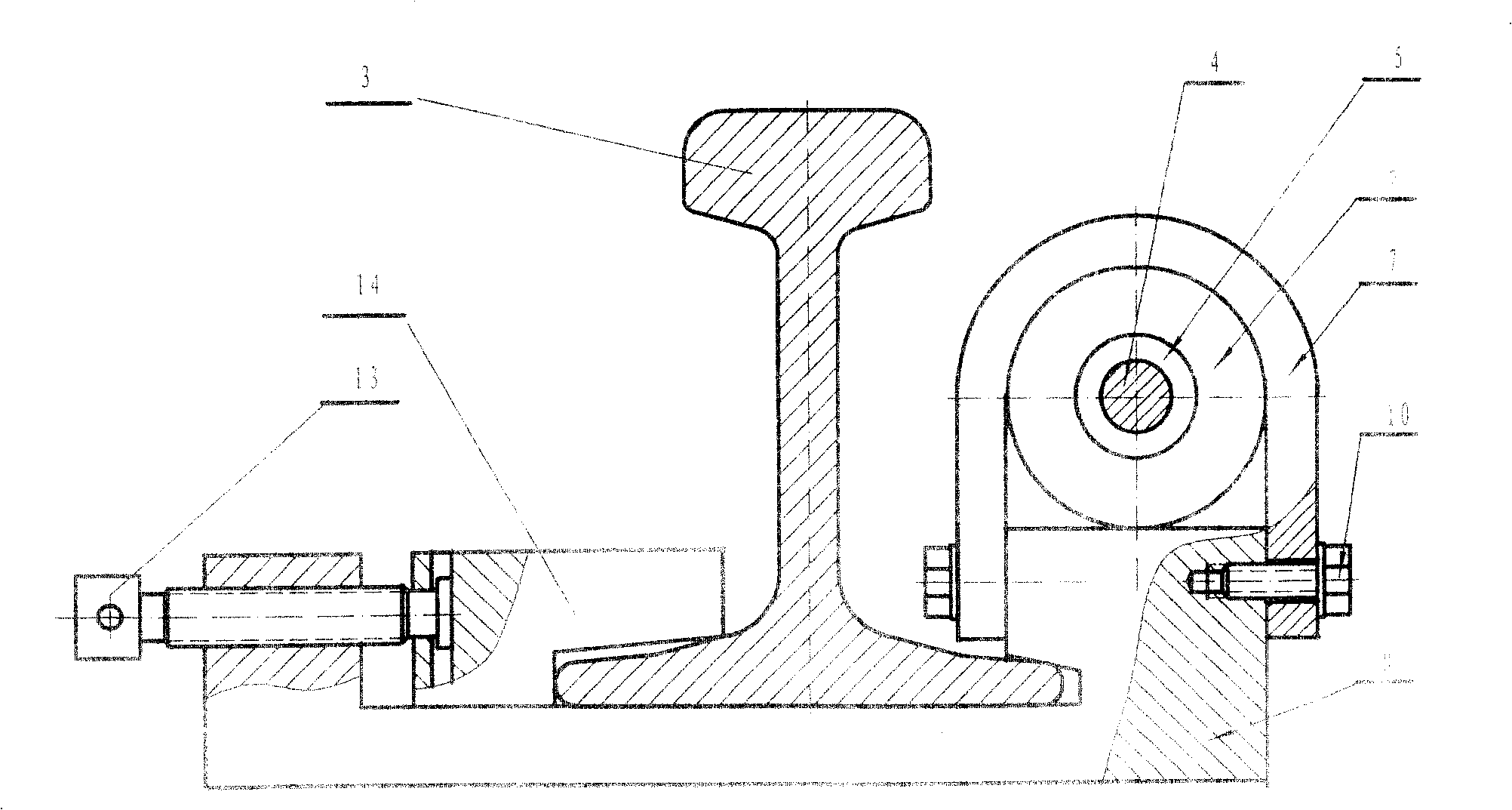

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] As shown in Figure 1, a fixed force-measuring device is installed on the measured part of the long rail. The force-measuring device is provided with a measuring rod 4. The measuring rod 4 is made of the same material as the measured long rail, and its cross section is circular. Members that need to be made into square or other cross-sectional shapes. One end of the measuring rod 4 is connected with the front fixed block 2 through the nut 1, and the other end is connected with the moving end 5 of the displacement sensor. Such as figure 2 The shown front fixing block 2 utilizes the front fastening bolt 11 and the front pressing block 12 to be fixedly connected with a measuring point of the long steel rail 3 . Such as image 3 The static end 6 of the displacement sensor is connected with the rear fixed block 8 through the fastening ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com