Particulate matter removing device of marine heavy-duty diesel engine EGR system

A technology for heavy-duty diesel engines and particulate matter, applied in the direction of charging systems, mechanical equipment, engine components, etc., can solve the problems of difficult effective control, poor practicability, and limited improvement, and achieve low development costs, reasonable design, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

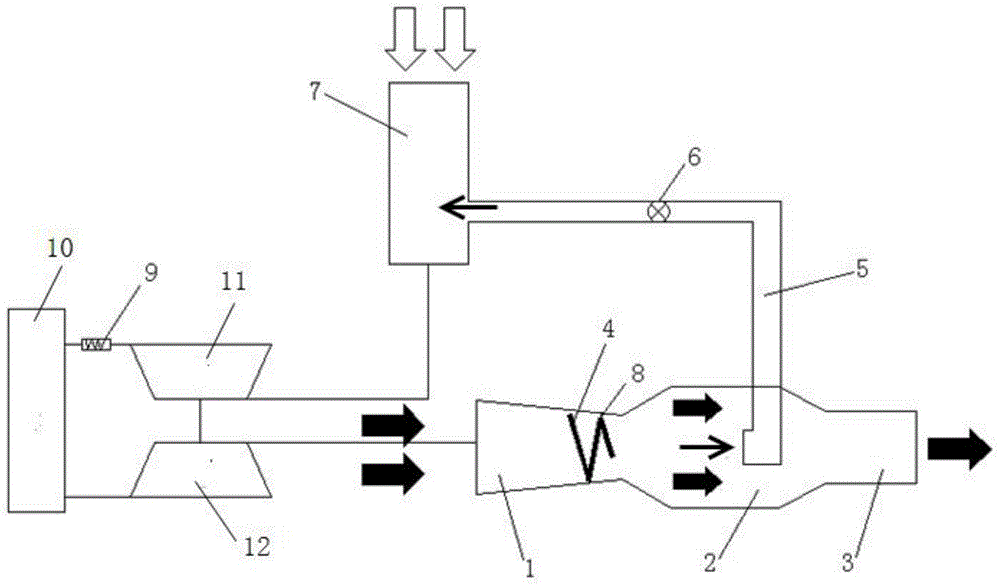

[0013] Such as figure 1 As shown, the present invention includes a conical turbine outlet pipe 1, a shuttle-shaped volume chamber 2, a rear exhaust pipe 3, a helical blade 4, an EGR pipeline 5, an EGR valve 6, a front air intake pipe 7, a helical blade fixing bracket 8, a middle Cooler 9, diesel engine 10, compressor 11, turbine 12, diesel engine 10 is connected with compressor 11 and turbine 12 through intake and exhaust pipelines, and intercooler 9 is arranged on the intake pipeline between diesel engine 10 and compressor 11 , the air outlet of the front end air intake pipe 7 is connected with the air inlet of the compressor 11 through the air intake pipeline, the conical turbine air outlet pipe 1, the shuttle-shaped volume chamber 2, and the rear end exhaust pipe 3 are connected together in turn, and the turbine 12 The air outlet is connected to the air inlet of the conical turbine outlet pipe 1 through the exhaust pipeline, the helical blade 4 is arranged in the conical tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com