Rocker arm compartment assembly for heavy-duty diesel engine

A heavy-duty diesel, rocker chamber technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., to achieve the effect of simple structure, reduction of rocker shaft mounts and their fixing devices, and a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

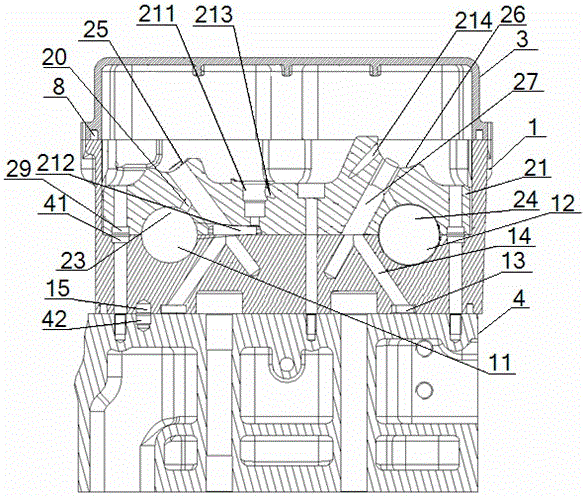

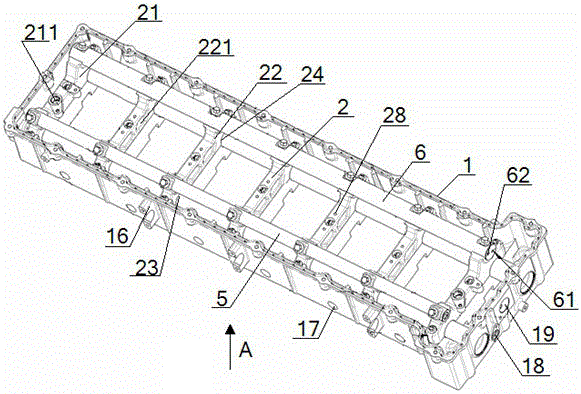

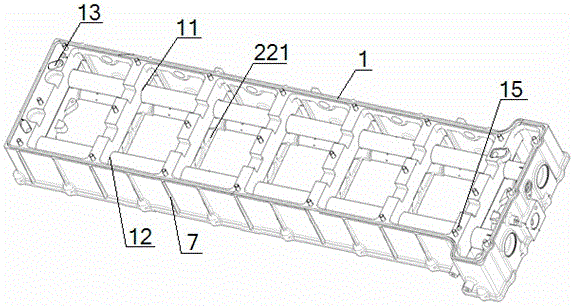

[0043] see Figure 1 to Figure 3 , a rocker chamber assembly for a heavy-duty diesel engine, comprising a rocker chamber 1 and a cam bearing cover 2, the top of the rocker chamber 1 is fixedly connected to the cylinder head cover 3, the rocker chamber 1, the cylinder head cover 3 The bottoms are provided with sealing grooves 8, the bottom of the rocker chamber 1 is fixedly connected to the top of the cylinder head 4, and the bottom of the rocker chamber 1 is provided with a positioning pin hole matching the cylinder head positioning pin hole 42 on the top of the cylinder head 4 15. The inner and outer surfaces of the two side plates of the rocker chamber 1 are provided with reinforcing ribs 7, and the outer side of the side plate near the intake rocker shaft 5 on the rocker chamber 1 is arranged with a high-pressure common rail installation surface 16 and a fuel injector. Mounting hole 17 for the high-voltage connecting pipe, the end of the rocker arm chamber 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com