Tube drawing mold

A technology of pipe drawing and drawing die, which is applied in the direction of wire drawing die, etc., can solve the problems of increasing the friction of the pipe blank, failing to meet the product precision requirements, and breaking the pipe blank, so as to reduce the drawing production cost, improve the quality, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

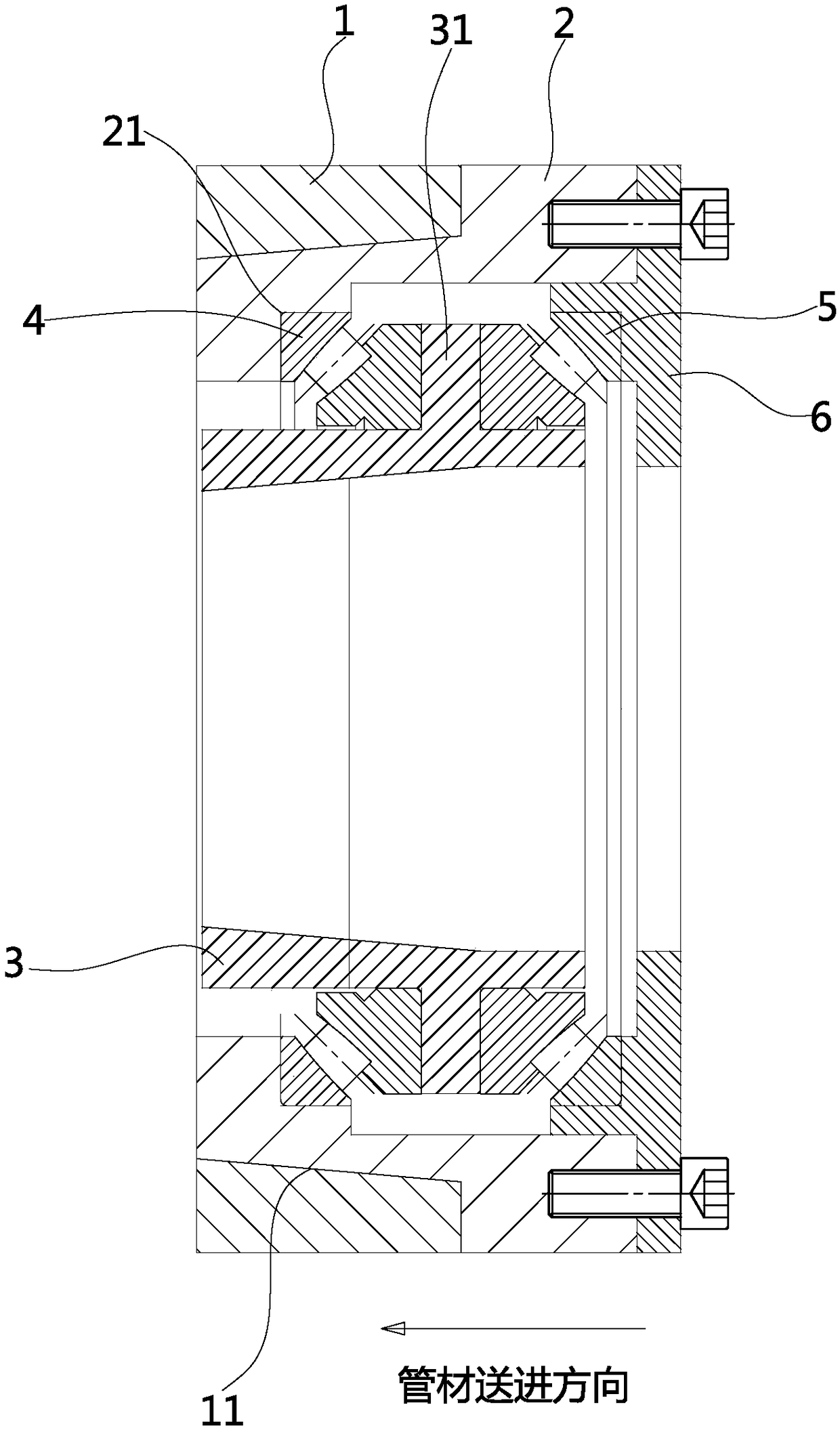

[0021] The invention discloses a drawing die, which includes a drawing die set and an inner die set, the inner die set is installed inside the drawing die set, the pipe drawing die also includes a bearing, and the bearing is installed on the between the inner die sleeve and the drawing die sleeve, so that the inner die sleeve can rotate under the action of circumferential stress difference. During the use of the drawing die, if the wall thickness of the incoming tube blank is not uniform, the circumferential stress difference caused by the different wall thickness of the tube blank will drive the inner mold sleeve around the drawing tube during the stretching process. The central axis of the mold sleeve rotates, and the sliding friction between the inner mold sleeve and the tube blank changes from sliding friction to rolling friction, so as to reduce the axial friction force on the tube blank during the drawing process, so that the force on the tube blank itself is more uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com