Vertical streamline tunnel wheel supercharger

A technology of supercharger and tunnel wheel, which is used in non-variable-capacity pumps, machines/engines, components of pumping devices for elastic fluids, etc. problems, to achieve the effect of reducing losses, reducing possibilities and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

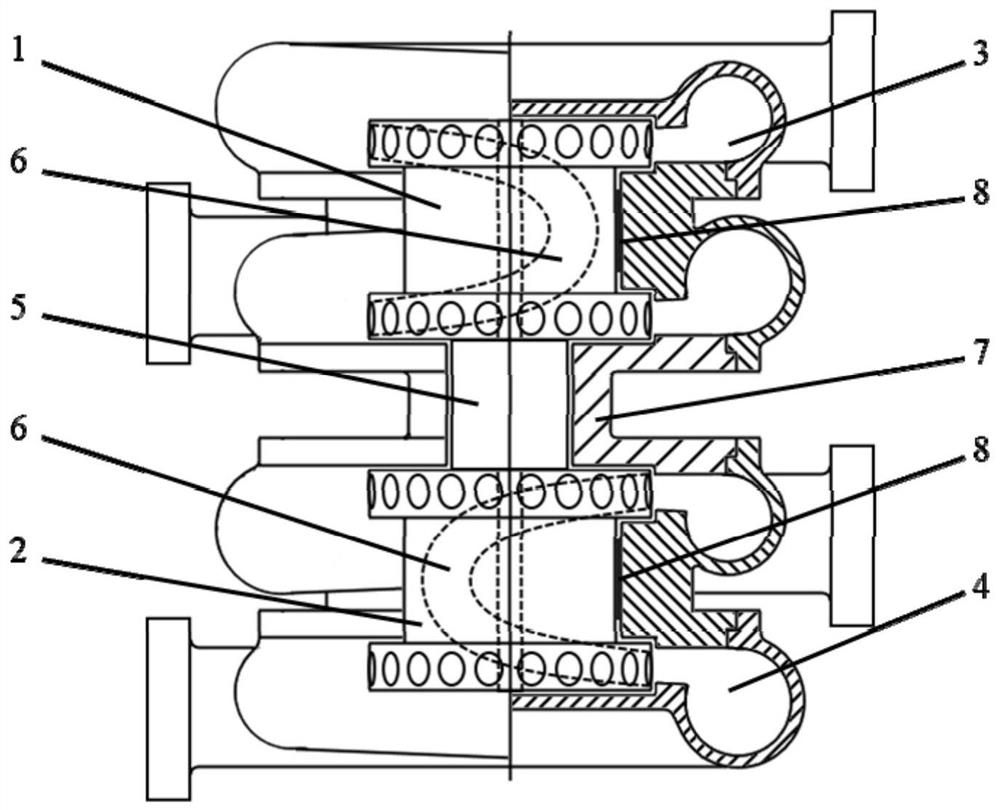

[0034]Such asfigure 1 As shown, the vertical streamline tunnel wheel supercharger, streamline tunnel compressor wheel 1, streamline tunnel turbine 2, compressor casing 3, turbine casing 4, and shaft 5; streamline tunnel compressor wheel 1 and The streamline tunnel turbine 2 is respectively installed at both ends of the rotating shaft 5 and forms a supercharger rotor; the rotating shaft 5 is arranged vertically and forms a vertical structure. In order to fix the turbocharger more stably, further, the rotating shaft 5 is arranged vertically and forms a vertical structure, which facilitates the use of a method of fixing the rotor at the upper and lower ends, which is more stable than a horizontal turbocharger. In order to form the streamline tunnel 6, further, the streamline tunnel compressor wheel 1 and the streamline tunnel turbine 2 are closed rotating mechanical structures, and the two structures can be completely the same; the streamline tunnel compressor wheel 1 and the streamlin...

Embodiment 2

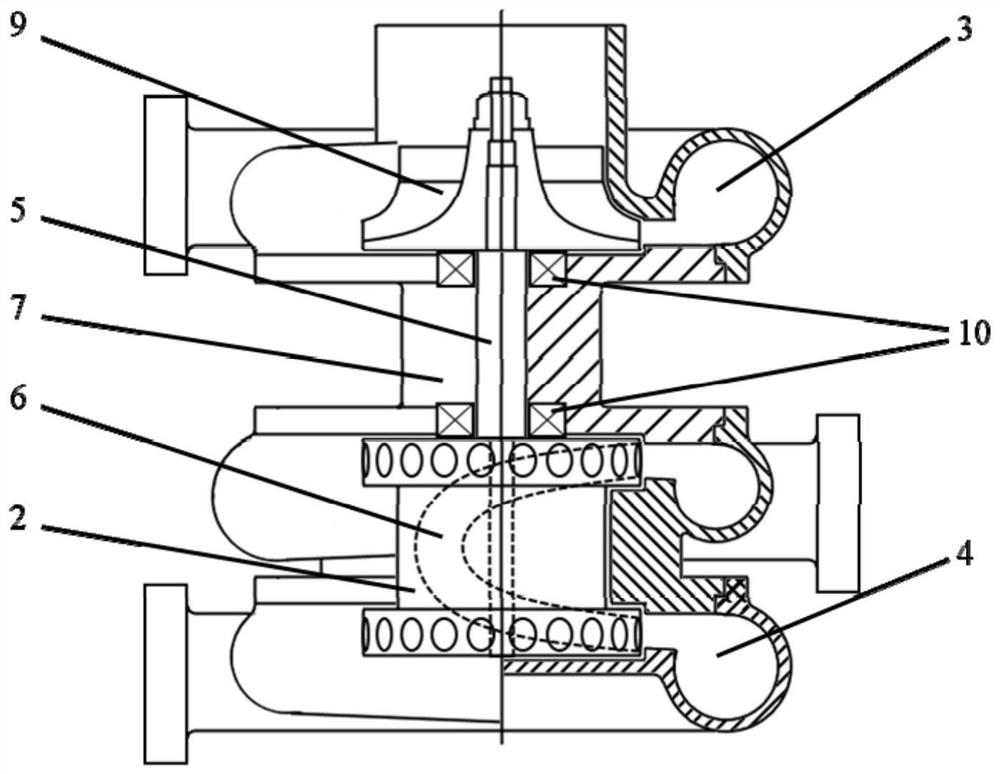

[0040]Such asfigure 2 As shown, with respect to Embodiment 1, in this embodiment, the supercharger rotor is composed of a vane compressor wheel 9 and a streamline tunnel turbine 2 installed at both ends of the rotating shaft 5.

[0041]Or the supercharger rotor is composed of a streamline tunnel compressor wheel 1 and a blade turbine. The streamline tunnel compressor wheel 1 and the blade turbine are installed at both ends of the rotating shaft 5.

[0042]The supporting bearings are ball bearings 10, which are respectively installed near the shaft diameters of the compressor end and the turbine end.

[0043]In summary, the vertical structure is adopted to avoid the influence of gravity on the rotor system and improve the stability of the bearing-rotor system; the turbine and compressor wheels adopt streamlined tunnel structures in structure. Compared with the blade structure, The structure of the turbine and the compressor wheel can be exactly the same, which can greatly reduce the design a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com