CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization

A heavy-duty diesel engine and circulation system technology, which is applied in the field of CO2 Rankine cycle system, can solve the problems of system complexity, natural cold source condensation, etc., and achieve high thermal power conversion efficiency, improved fuel utilization rate, and low pump power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

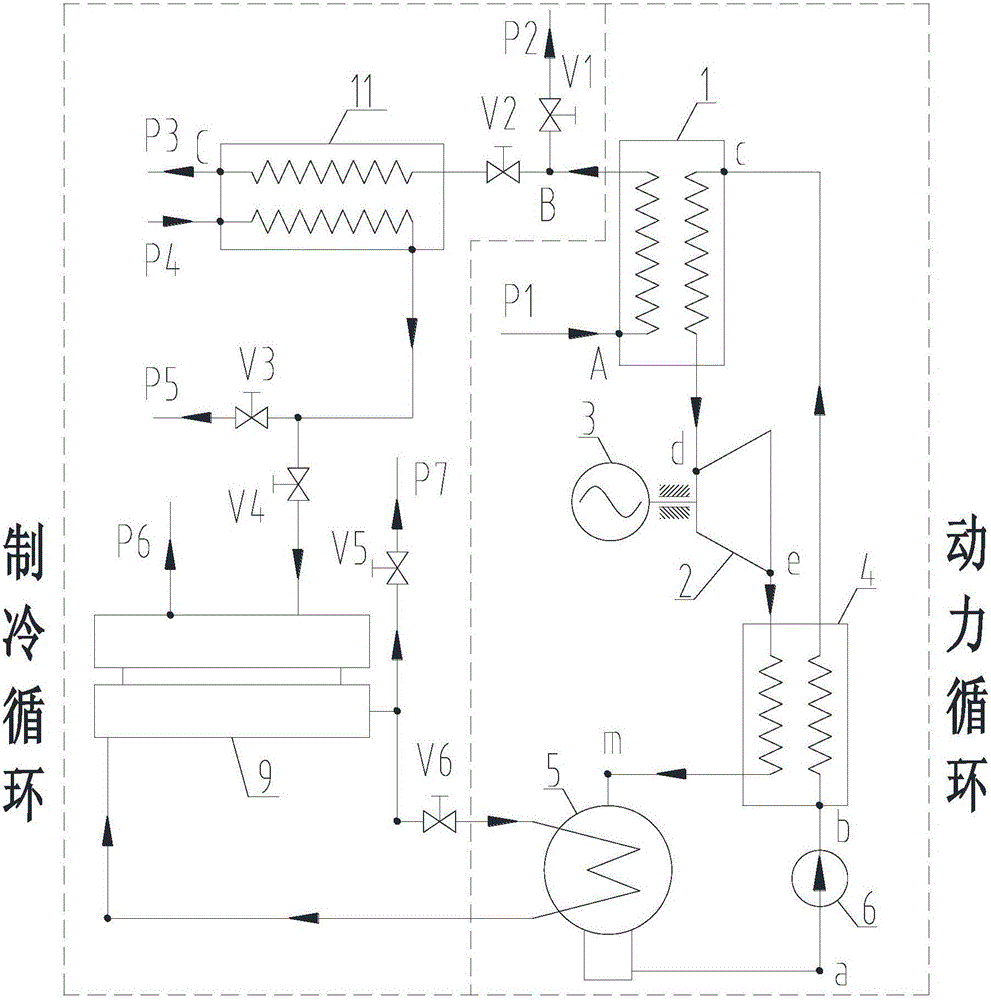

[0041] A kind of CO used for cascade utilization of waste heat of heavy-duty diesel engine 2 Rankine cycle system, such as figure 1 As shown, the system mainly includes a flue gas waste heat exchanger 1, a primary CO 2 Turbine 2, power equipment 3, regenerator 4, condenser 5, high-pressure pump 6, single-effect absorption refrigerator 9, flue gas water heater 11, pipelines, valves, etc.

[0042] The circulatory system mainly consists of the following two parts:

[0043] Power cycle: CO from condenser 5 2 The liquid (state point a) is first pressurized by the high-pressure pump 6 to the state point b, then heated to the state point c in the regenerator 4, and then heated to the state point d in the flue gas waste heat exchanger 1, and then enters the first stage CO 2 Turbine 2 expands to do work, which is used to generate electricity or drive other equipment. Level 1 CO 2 The exhaust gas from the turbine (state point e) is cooled to the state point m by the regenerator 4 ...

Embodiment 2

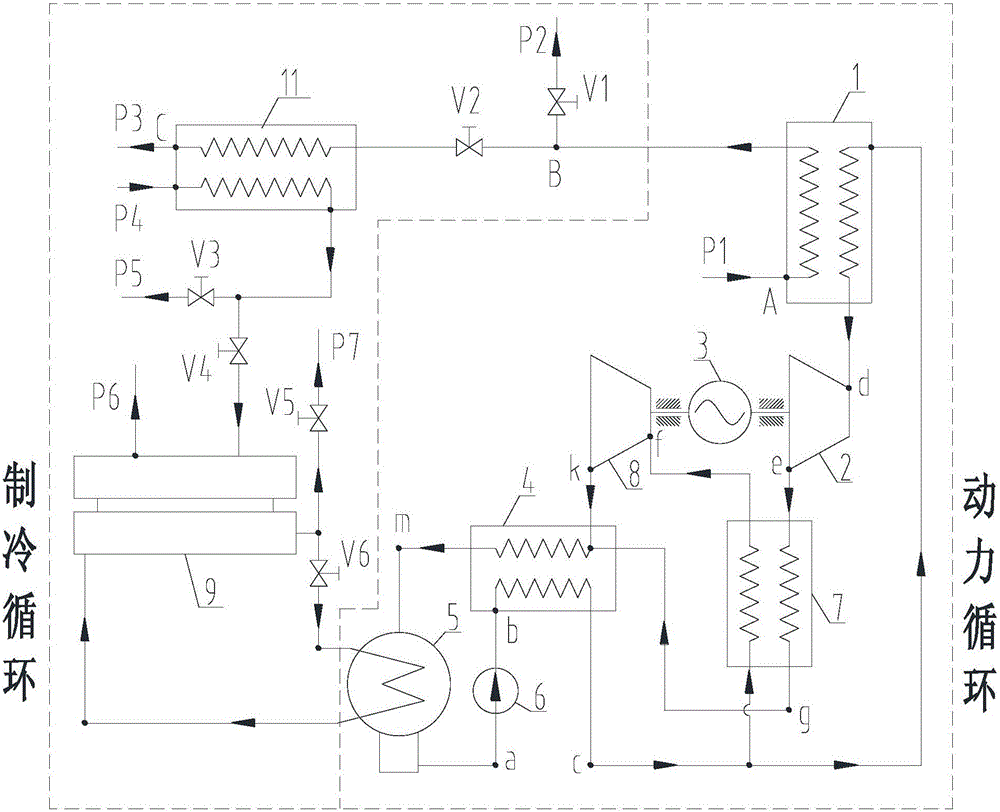

[0047] A kind of CO used for cascade utilization of waste heat of heavy-duty diesel engine 2 Rankine cycle system, such as figure 2 As shown, the system mainly includes a flue gas waste heat exchanger 1, a primary CO 2 Turbine 2, power equipment 3, regenerator 4, condenser 5, high pressure pump 6, CO 2 Heat exchanger 7, secondary CO 2 Turbine 8, single-effect absorption refrigerator 9, flue gas water heater 11, pipelines, valves, etc. The system is mainly composed of a power cycle and a refrigeration cycle, wherein the refrigeration cycle is the same as in Embodiment 1, and only the power cycle is introduced below:

[0048] Power cycle: CO from condenser 5 2 The liquid (state point a) is first pressurized to state point b by the high-pressure pump 6, and then enters the regenerator 4 to absorb secondary CO 2 Turbine 8 and CO 2The exhaust gas waste heat of the heat exchanger 7 is heated up to the state point c, and then divided into two paths. The first path is heated to...

Embodiment 3

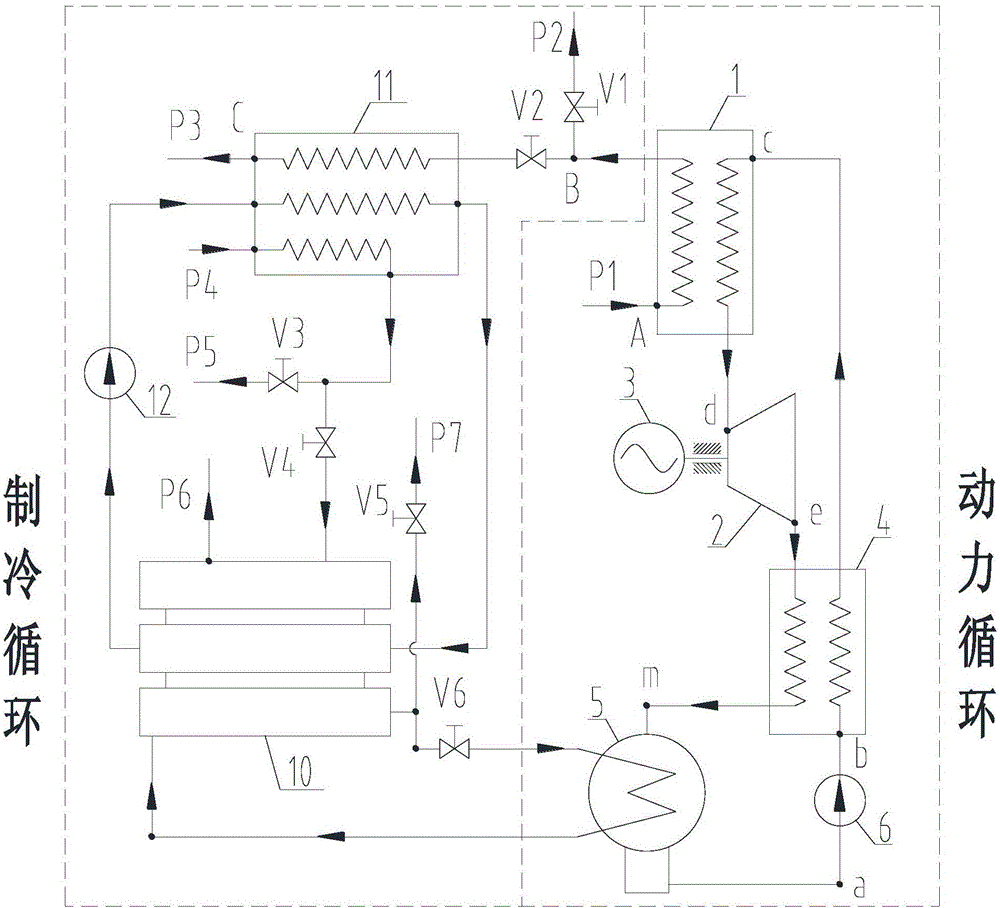

[0051] A kind of CO used for cascade utilization of waste heat of heavy-duty diesel engine 2 Rankine cycle system, such as image 3 As shown, the system mainly includes a flue gas waste heat exchanger 1, a primary CO 2 Turbine 2, power equipment 3, regenerator 4, condenser 5, high-pressure pump 6, double-effect absorption refrigerator 10, flue gas water heater 11, circulating water pump 12, pipelines, valves, etc. The system is mainly composed of a power cycle and a refrigeration cycle, wherein the power cycle is the same as in Embodiment 1, and only the refrigeration cycle is introduced below:

[0052] Refrigeration cycle: In order to improve the refrigeration coefficient of the refrigerator, the single-effect absorption refrigerator 9 in the first embodiment is replaced by a double-effect absorption refrigerator 10 in this cycle. Therefore, in addition to the low-temperature heat source in Embodiment 1, a set of medium-temperature hot water self-circulation circuit driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com