Non-automotive heavy-duty diesel engine SCR (semiconductor control rectifier) device and method

A technology for heavy-duty diesel engines and vehicles. It is applied in the direction of noise reduction devices, exhaust devices, and electronic control of exhaust gas treatment devices. It can solve problems such as reducing NH, improve NOX conversion rate, improve and reduce NH3 escape amount, and reduce NH3. The effect of escape volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

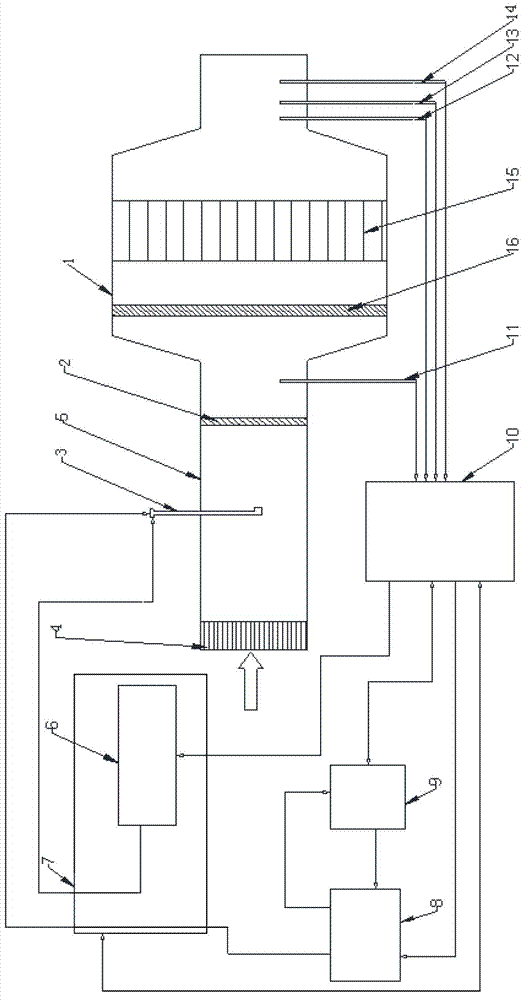

[0039] Please refer to shown in Fig. 1, it is the preferred embodiment system device diagram of the present invention, comprises reactor 1, and reactor 1 is provided with deflector grille 4, mixer 2, diffuser 16 and catalyst 15 successively from tail gas inlet to tail gas outlet Between the diversion grid 4 and the mixer 2 is the mixing tube 5 where the exhaust gas and urea solution are mixed, wherein the diversion grid 4 is a porous mesh grid structure, and the mixer 2 is a blade staggered stacked structure The device can also be replaced by an impeller to facilitate the generation of vortex and make the mixed gas mix more evenly. The diffuser 16 is a steel plate densely covered with through holes, and the catalyst 15 is selected for stacking of honeycomb catalysts. A pressure measurement unit 12, a temperature measurement unit 13 and a NO X Measuring unit 14, the aforementioned three measuring units are connected with the system control device 10 to provide each parameter va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com