High-oil refined corn gluten meal and preparation method thereof

A technology of corn gluten powder and corn gluten, which is applied in plant protein processing, animal feed, animal feed, etc., can solve problems such as fat deficiency, and achieve the effects of increasing energy concentration, fast feed intake, and fast improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Made from the following raw materials and methods in parts by weight:

[0036] 40 parts of corn gluten powder;

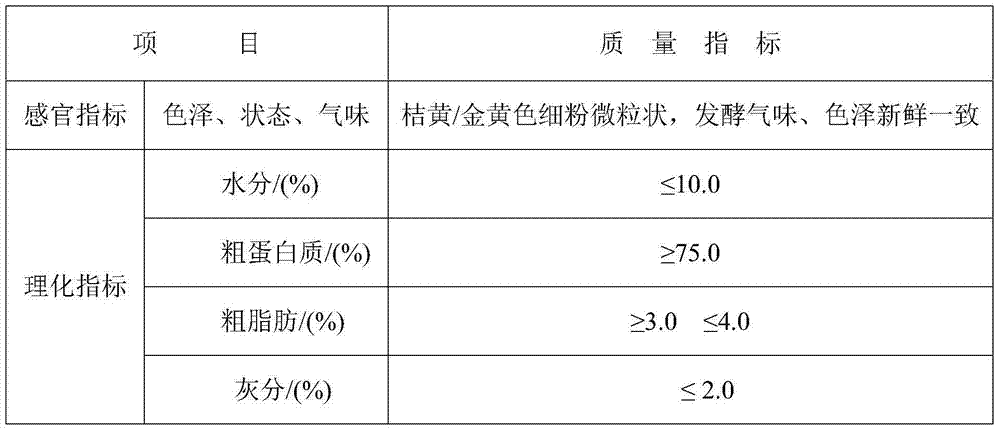

[0037] 6 parts of high-fat sugar protein powder;

[0038] method:

[0039] (1) Prepare corn gluten powder into corn gluten milk with a concentration of 40%, adjust the pH value to 5.6, and stir evenly;

[0040] (2) Put corn gluten milk in a constant temperature water bath and heat to 85°C, stir, and keep warm for gelatinization for 45 minutes;

[0041] (3) High-fat glycoprotein powder is prepared into high-fat glycoprotein milk with a concentration of 40%, added to the corn gluten milk after the above reaction, and stirred evenly;

[0042] (4) Filter and wash at 80°C, and dry in an oven at 60°C.

Embodiment 2

[0044] Made from the following raw materials and methods in parts by weight:

[0045] 50 parts of corn gluten powder;

[0046] 10 parts of high-fat sugar protein powder;

[0047] method:

[0048] (1) Prepare corn gluten powder into corn gluten milk with a concentration of 40%, adjust the pH value to 5.8, and stir evenly;

[0049](2) Put corn gluten milk in a constant temperature water bath and heat to 85°C, stir, and keep warm for gelatinization for 50 minutes;

[0050] (3) High-fat glycoprotein powder is prepared into high-fat glycoprotein milk with a concentration of 40%, added to the corn gluten milk after the above reaction, and stirred evenly;

[0051] (4) Filtration and washing at 80°C, and oven drying at 60°C;

Embodiment 3

[0053] Made from the following raw materials and methods in parts by weight:

[0054] 60 parts of corn gluten powder;

[0055] 14 parts of high-fat sugar protein powder;

[0056] method:

[0057] (1) Prepare corn gluten powder into corn gluten milk with a concentration of 40%, adjust the pH value to 6.0, and stir evenly;

[0058] (2) Put corn gluten milk in a constant temperature water bath and heat to 85°C, stir, and keep warm for gelatinization for 55 minutes;

[0059] (3) High-fat glycoprotein powder is prepared into high-fat glycoprotein milk with a concentration of 40%, added to the corn gluten milk after the above reaction, and stirred evenly;

[0060] (4) Filtration and washing at 80°C, and oven drying at 60°C;

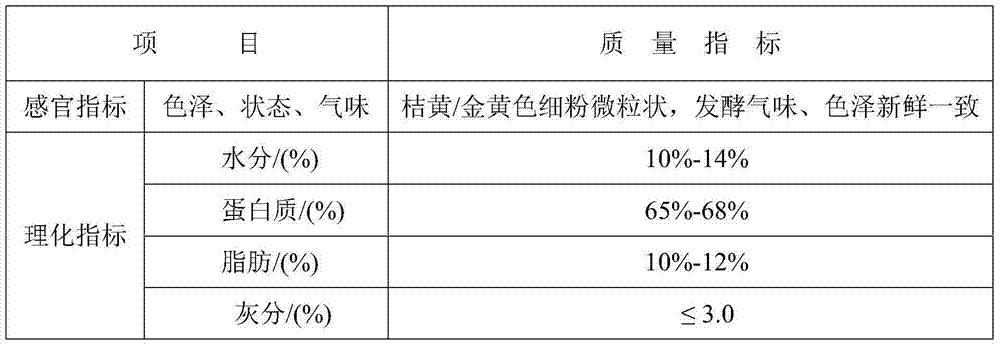

[0061] Each embodiment product detection result:

[0062] project

[0063] It can be seen from the above results that the technical method of the present invention can be used to prepare crude protein content (moisture basis) / %≧65%, crude fat (%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com