A kind of lipid-lowering phospholipid and phytosterol composite nutrition and preparation method thereof

A technology for phytosterols and nutritional products, applied in the field of health food, can solve the problems that raw materials cannot be directly mixed evenly, and the dosage form is single, and achieves the effects of ensuring particle uniformity, easy portability, and reducing greasy feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

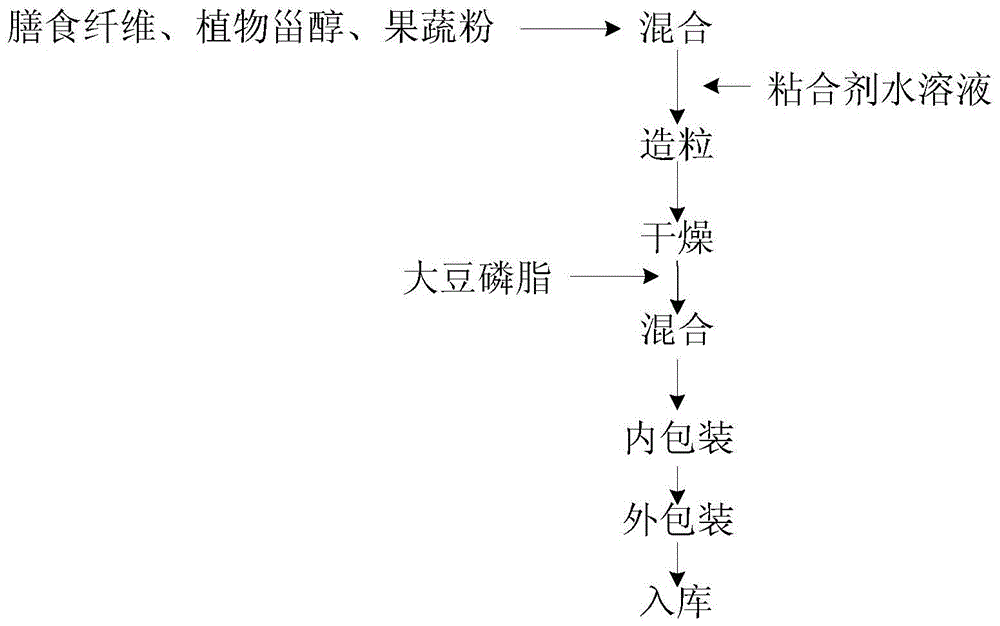

Method used

Image

Examples

Embodiment 1

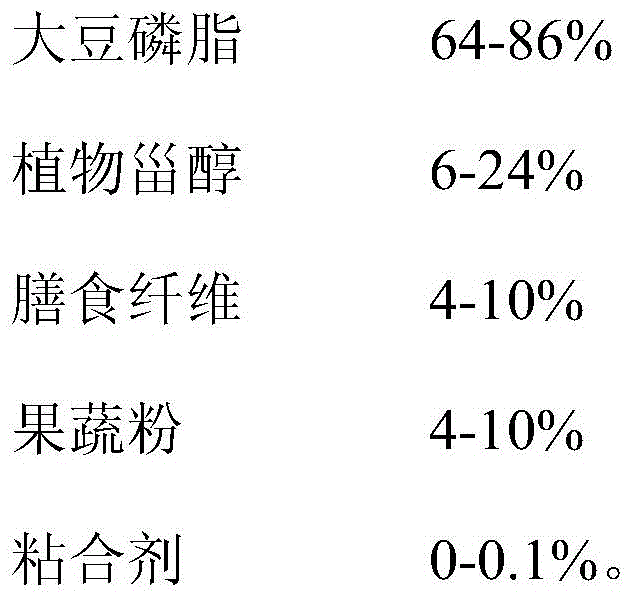

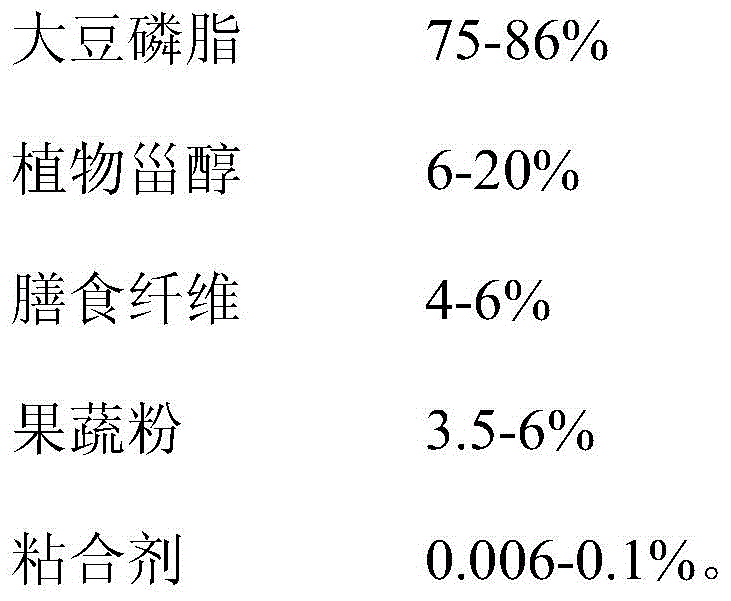

[0045] Specific formula: soybean lecithin: 86%, phytosterol 6%, apple fiber 4%, blueberry powder 3.99%, sodium carboxymethylcellulose 0.01%.

[0046] The preparation process is as follows:

[0047] (1) Receive all raw and auxiliary materials that have passed the inspection as required, including soybean lecithin, phytosterols, apple fiber, blueberry powder, and sodium carboxymethyl cellulose. After removing the outer packaging, transfer them to a 100,000-class clean area for future use;

[0048] (2) Pass the apple fiber, phytosterol, and blueberry powder through a 40-mesh sieve. If the mesh size is less than 40 mesh, impurities and foreign matter cannot be removed, and it is not conducive to mixing evenly during granulation;

[0049] (3) After weighing phytosterols, apple fiber, and blueberry powder according to the proportioning ratio, add a tank mixer and mix for 5 minutes, add an aqueous solution containing 1wt% sodium carboxymethylcellulose in the mixed material, and an aq...

Embodiment 2

[0056] Specific formula: soybean lecithin 64%, phytosterol 24%, oat fiber 10%, banana powder 1.9%, hydroxypropyl methylcellulose 0.1%.

[0057] The preparation process is as follows:

[0058] (1) Receive all raw and auxiliary materials that pass the inspection as required, including soybean lecithin, phytosterols, oat fiber, banana powder, and hydroxypropyl methylcellulose, remove the outer packaging and transfer them to a 100,000-class clean area for standby;

[0059] (2) Pass oat fiber, phytosterols, and banana powder through a 60-mesh sieve. If the mesh size is greater than 60 mesh, some raw materials will not be able to pass through the sieve and will be wasted, and the sieving time will be significantly increased, reducing production efficiency;

[0060] (3) After weighing phytosterols, oat fiber, and banana powder according to the ratio of raw materials, they were added to a tank mixer and mixed for 5 minutes, and an aqueous solution containing 5wt% hydroxypropyl methylc...

Embodiment 3

[0067] Specific formula: soybean lecithin 80.5%, phytosterol 10%, corn fiber 6%, apple powder 3.494%, sodium carboxymethyl cellulose 0.006%.

[0068] In the preparation process, except that the sieve mesh number in the step (2) is 50 meshes, the sodium carboxymethylcellulose aqueous solution containing 0.5wt% is added in the step (3), and the addition amount of the aqueous solution containing the binder is to make the binder consumption To meet the formula ratio, the mesh size of the sieve granulator is 12 mesh, and other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com