Antibacterial bone cement and preparation method thereof

An antibacterial bone and bone cement technology, used in medical science, tissue regeneration, prosthesis, etc., can solve the problems of lack of biological activity, hinder bacterial DNA replication, and cannot degrade and absorb, and achieve the effect of enhancing biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

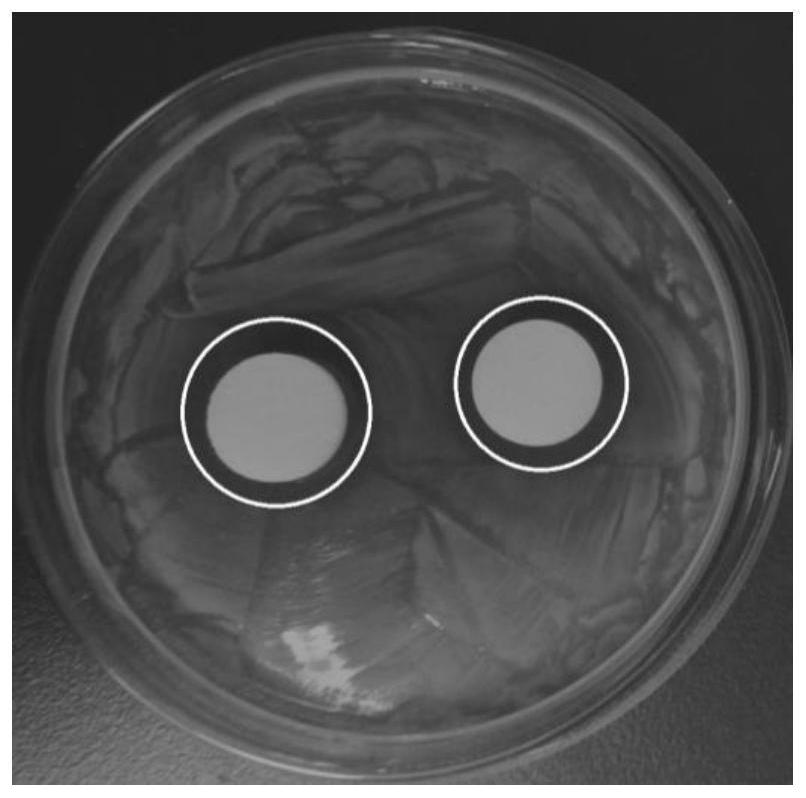

Image

Examples

Embodiment 1

[0021] An antibacterial bone cement, mainly composed of the following raw materials in mass percentage: the powder is 55% of polyacrylate, 40% of silver and barium sulfate composite powder, and 5% of benzoyl peroxide; the liquid is N, N-dimethyl 0.5% of p-toluidine, 0.05% of hydroquinone, and 99.45% of methyl methacrylate; in the composite powder of silver and barium sulfate, Ag accounts for 0.5% by mass of the composite powder of silver and barium sulfate.

[0022] The preparation method of the antibacterial bone cement of the present embodiment comprises the steps:

[0023] S1, preparation mass percent is the silver nitrate solution of 1.57%;

[0024] S2. Add barium sulfate powder into the silver nitrate solution and mix for 60 minutes, wherein the mass ratio of barium sulfate to silver nitrate solution is 2:1;

[0025] S3, drying in an oven at 120° C. for 5 hours, and ball milling after drying to obtain silver nitrate / barium sulfate composite powder with a thickness of 0.5...

Embodiment 2

[0031] An antibacterial bone cement, mainly composed of the following raw materials in mass percentage: the powder is 89% of polyacrylate, 10% of silver and barium sulfate composite powder, 1% of benzoyl peroxide; the liquid is N, N-dimethyl 5% p-toluidine, 2% hydroquinone, and 93% methyl methacrylate; in the silver and barium sulfate composite powder, Ag accounts for 5% of the mass percentage of the silver and barium sulfate composite powder.

[0032] The preparation method of the antibacterial bone cement in the present embodiment comprises the steps:

[0033] S1, preparation mass percentage is the silver nitrate solution of 20%;

[0034] S2. Add the barium sulfate powder into the silver nitrate solution and mix for 30 minutes, wherein the mass ratio of the barium sulfate to the silver nitrate solution is 2.54:1;

[0035] S3, drying in an oven at 60° C. for 24 hours, and ball milling after drying to obtain a silver nitrate / barium sulfate composite powder of 0.5-45 μm;

[0...

Embodiment 3

[0040] An antibacterial bone cement, mainly composed of the following raw materials in mass percentage: the powder is 68% of polyacrylate, 30% of silver and barium sulfate composite powder, 2% of benzoyl peroxide; the liquid is N, N-dimethyl 2% p-toluidine, 0.1% hydroquinone, 97.9% methyl methacrylate. In the composite powder of silver and barium sulfate, Ag accounts for 1% by mass of the composite powder of silver and barium sulfate.

[0041] The preparation method of the antibacterial bone cement of the present embodiment comprises the steps:

[0042] S1, preparation mass percent is the silver nitrate solution of 4.78%;

[0043] S2. Add barium sulfate powder into the silver nitrate solution and mix for 30 minutes, wherein the mass ratio of barium sulfate to silver nitrate solution is 3:1;

[0044] S3, drying in an oven at 100° C. for 24 hours, and ball milling after drying to obtain a silver nitrate / barium sulfate composite powder of 0.5-45 μm;

[0045] S4. Transfer the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com