Lubricating Oil Composition

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, base materials, additives, etc., can solve the problems of increasing fuel consumption, increasing the viscosity of low and high temperature lubricant, and unable to meet the requirements of low and high temperature viscosity, so as to improve the fuel economy and wear performance of a heavy duty diesel engine. , the effect of improving the fuel economy and wear performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

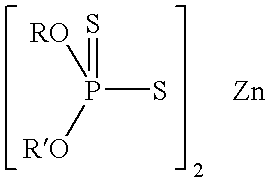

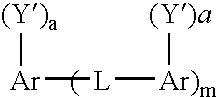

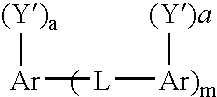

[0120]A SAE 5W40 grade lubricants containing base stock, dispersant (combination of borated dispersant and non-borated dispersant), detergent (a combination of calcium phenate, calcium sulfonate and magnesium sulfonate detergents), ZDDP, soot dispersant, a combination of ashless, sulfur-free phenolic and aminic antioxidants (0.7 mass % total), a molybdenum dithiocarbamate compound, viscosity modifier, pour point depressant and 1 mass % of 950 Mn polybutene (PIB) was formulated consistent with API CJ-4 and CI-4 specifications (1.0 mass % SASH; 0.4 mass % sulfur and 0.12 mass % phosphorus) in a blend of 4 and 6 cSt. Group III base stocks. The resulting oil had a boron content of 65 ppm, a magnesium content of 1156 ppm, a molybdenum content of 44 ppm and a TBN of 9.9; 79% of the TBN contributed by overbased detergent (52% of the TBN of the composition), was provided by the overbased magnesium detergents.

[0121]Valve train wear resulting from the use of the above lubricant was measured i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com