Cylinder head and overhead camshaft engine

A technology of cylinder head and camshaft, applied in the direction of engine components, machine/engine, cylinder head, etc., can solve the problem of restricting the miniaturization of the engine, and achieve the effect of simple structure, reduced size and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

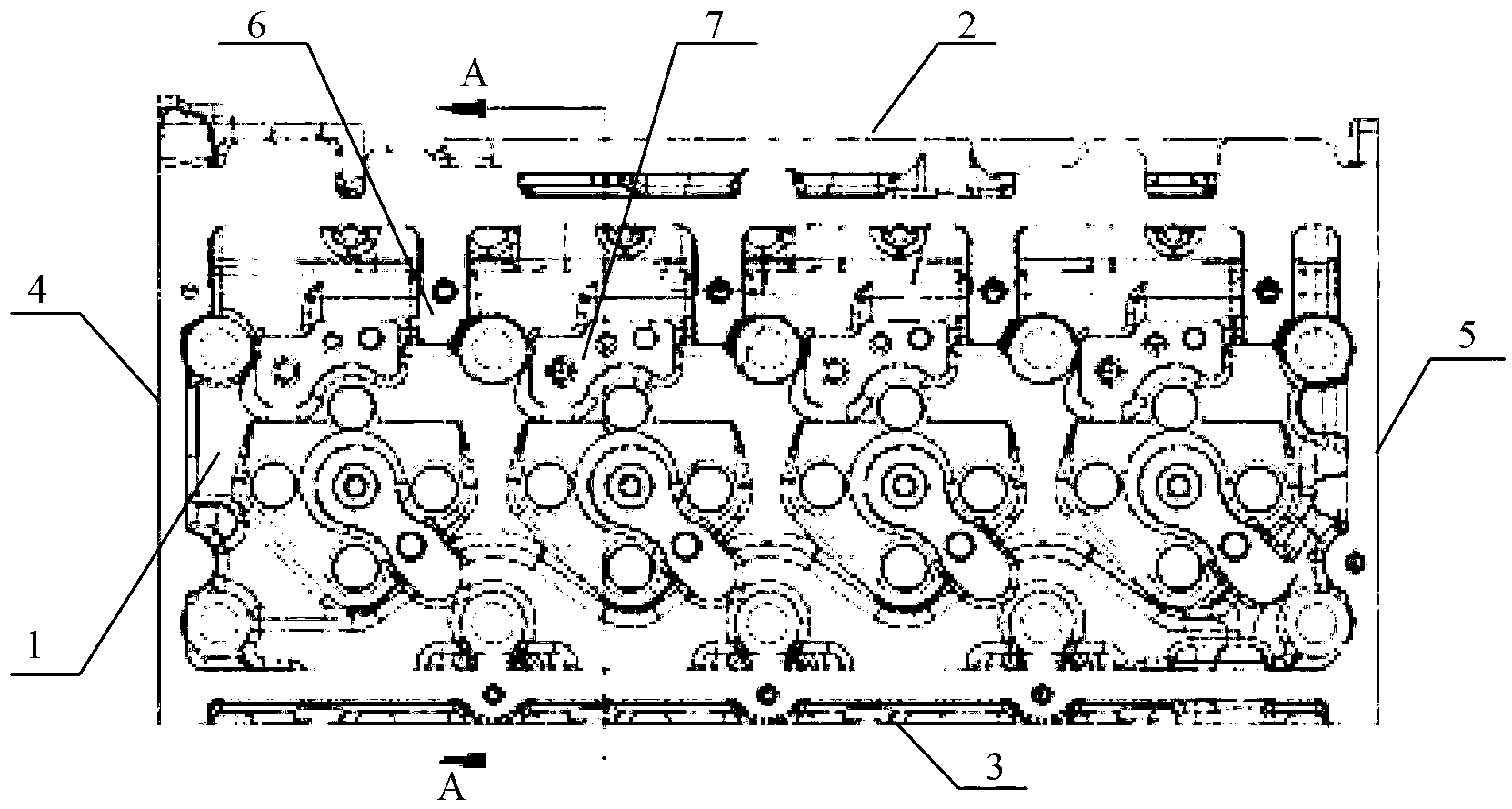

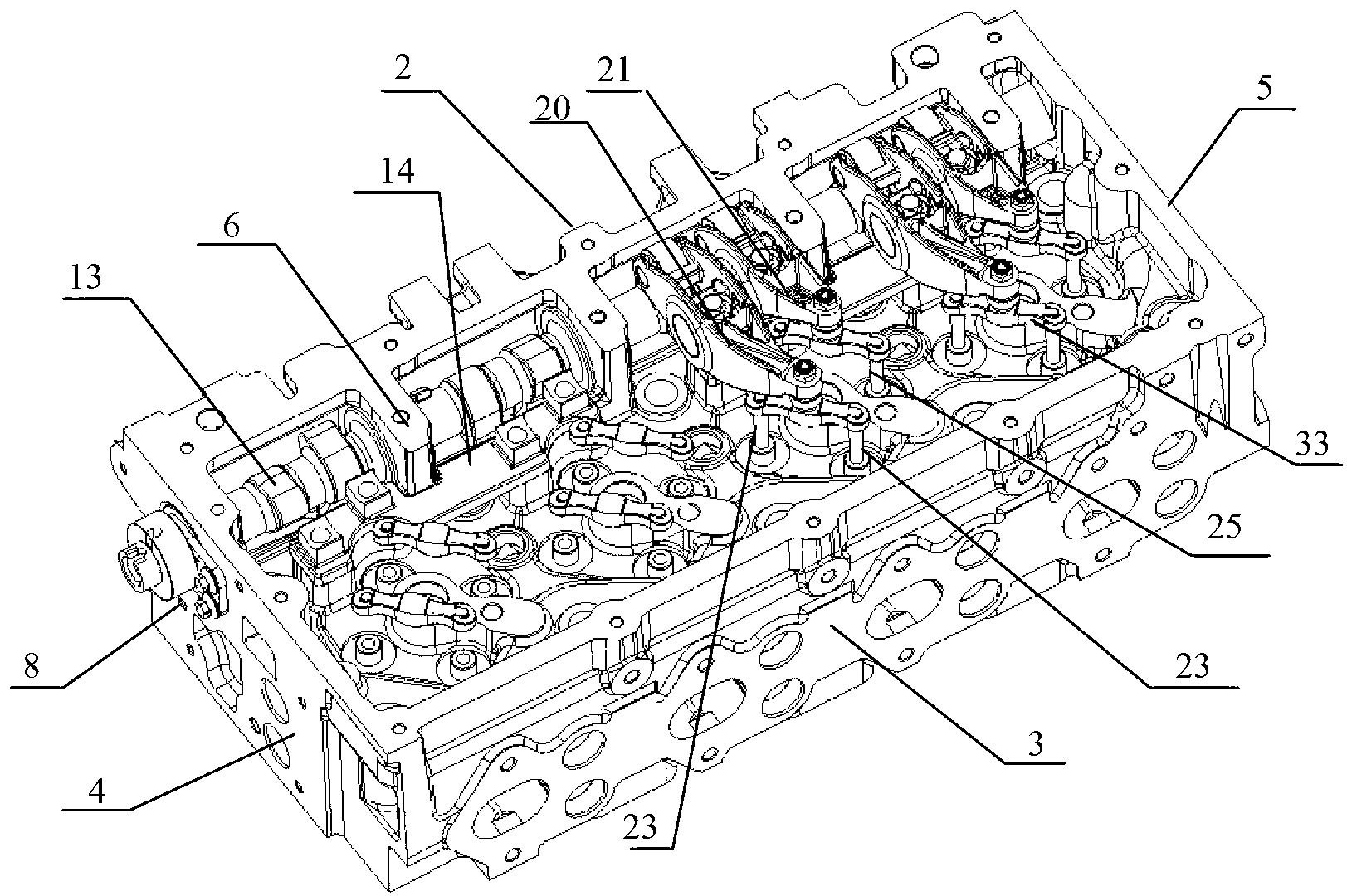

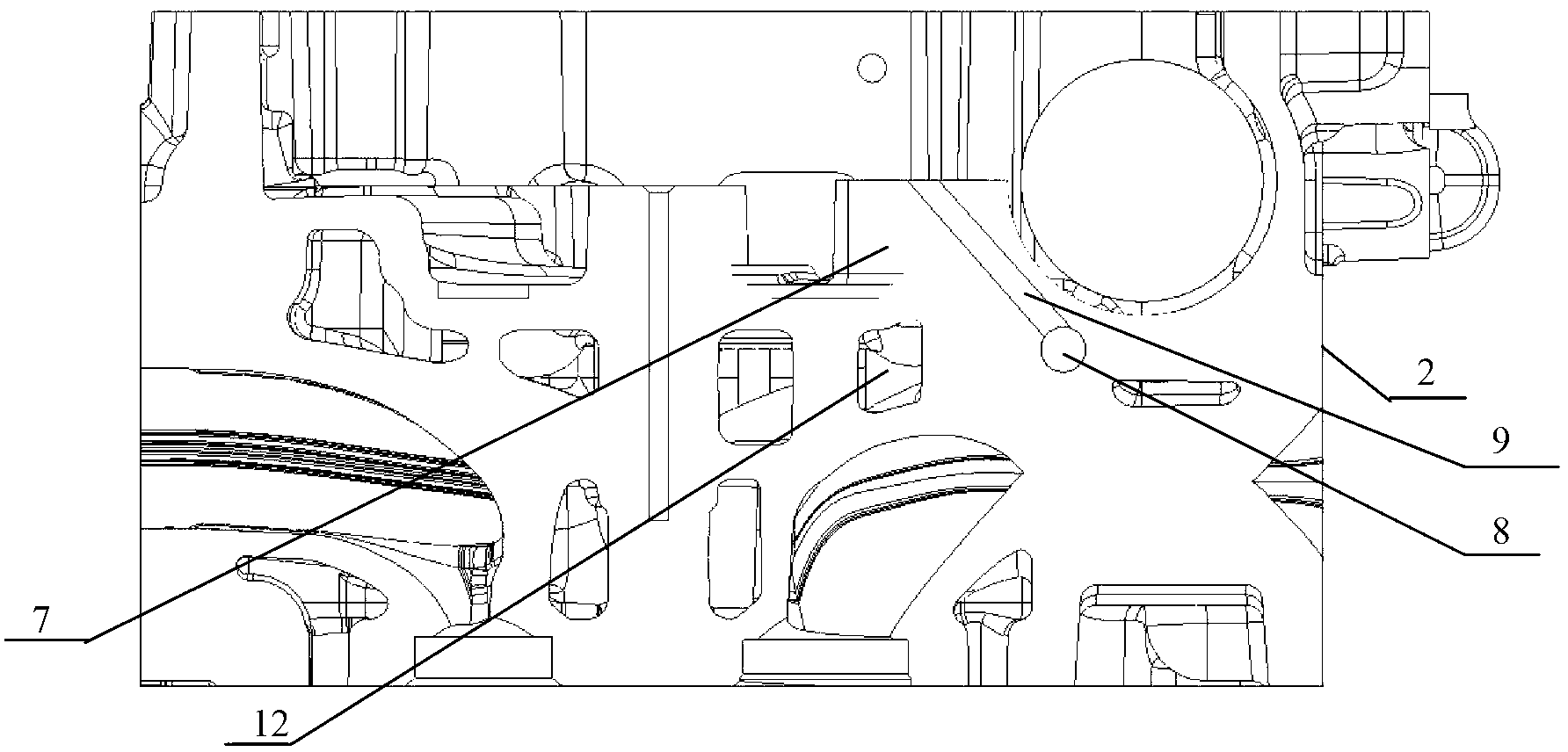

[0031] combine figure 1 and figure 2 , The cylinder head has a top surface 1, an intake side 2 with intake ports distributed, an exhaust side 3 with exhaust ports distributed, a front end face 4 facing the timing train and a rear end face 5 opposite to the front end face 4. Those of ordinary skill in the art should understand that the top surface 1 is defined relative to the bottom surface (not marked) of the cylinder head in contact with the cylinder block (not shown), while the front end surface 4 and the rear end surface 5 are relative to the positions of the timing gear train Defined, of course, other definition methods can also be used. On the top surface 1, a camshaft mounting seat 6 is distributed, and a rocker arm support mounting boss 7 is distributed near it. The oil return passage 8 extends from the front end face 4 to the rear end face 5, thereby penetrating the entire cylinder head between the front end face and the rear end face, as a part of the cylinder lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com