Test bed for valve actuating mechanism of engine with top-mounted cam shafts

A gas distribution mechanism and overhead cam technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problem of simulating the valve mechanism of an overhead camshaft engine, which cannot effectively and truly reflect the overhead Problems such as the working state of the valve mechanism of the camshaft engine and the inability to accurately carry out the test of the valve mechanism of the overhead camshaft engine have achieved the effect of ensuring accuracy and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, further illustrate structure of the present invention and mode of operation:

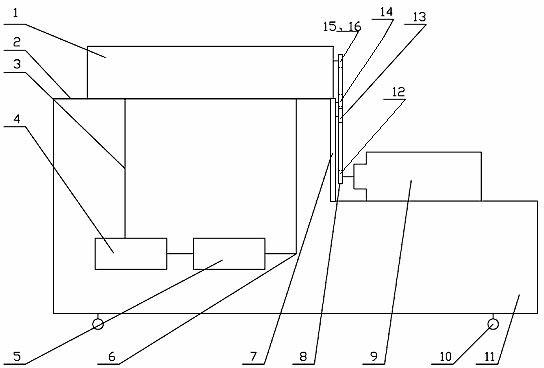

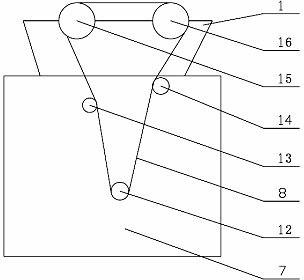

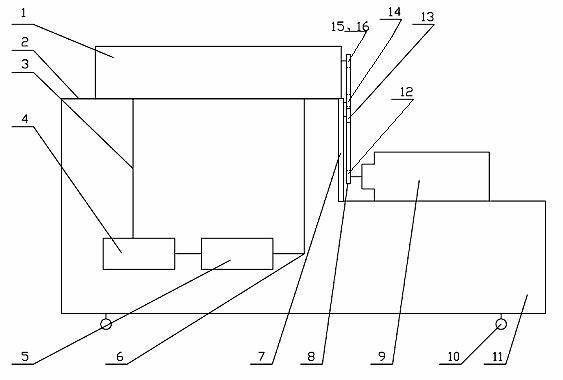

[0016] according to figure 1 The gas distribution mechanism test bench is built with the structure shown, and its composition includes: cylinder head connecting plate 2, oil return pipe 3, fuel tank 4, oil pump 5, oil inlet pipe 6, front wheel train plate 7, timing belt or chain 8, motor 9 11. The supporting trolley of the test bench. Fix the double overhead camshaft cylinder head 1 on the cylinder head connecting plate 2, fix the double overhead camshaft cylinder head 1, the cylinder head connecting plate 2 and the motor 9 on the test bench supporting trolley 11, and the test bench supporting trolley 11 Steering wheels 10 are installed below to facilitate movement. Make the front wheel train plate 7 according to the engine timing train structure, as figure 2 As shown, the front wheel train plate 7 is vertically fixed on the lower side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com