OHC overhead camshaft internal combustion enjine

A technology for camshafts and internal combustion engines, which is applied to valve devices, mechanical equipment, valve drive devices, etc., can solve problems such as trouble, and achieve the effect of firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

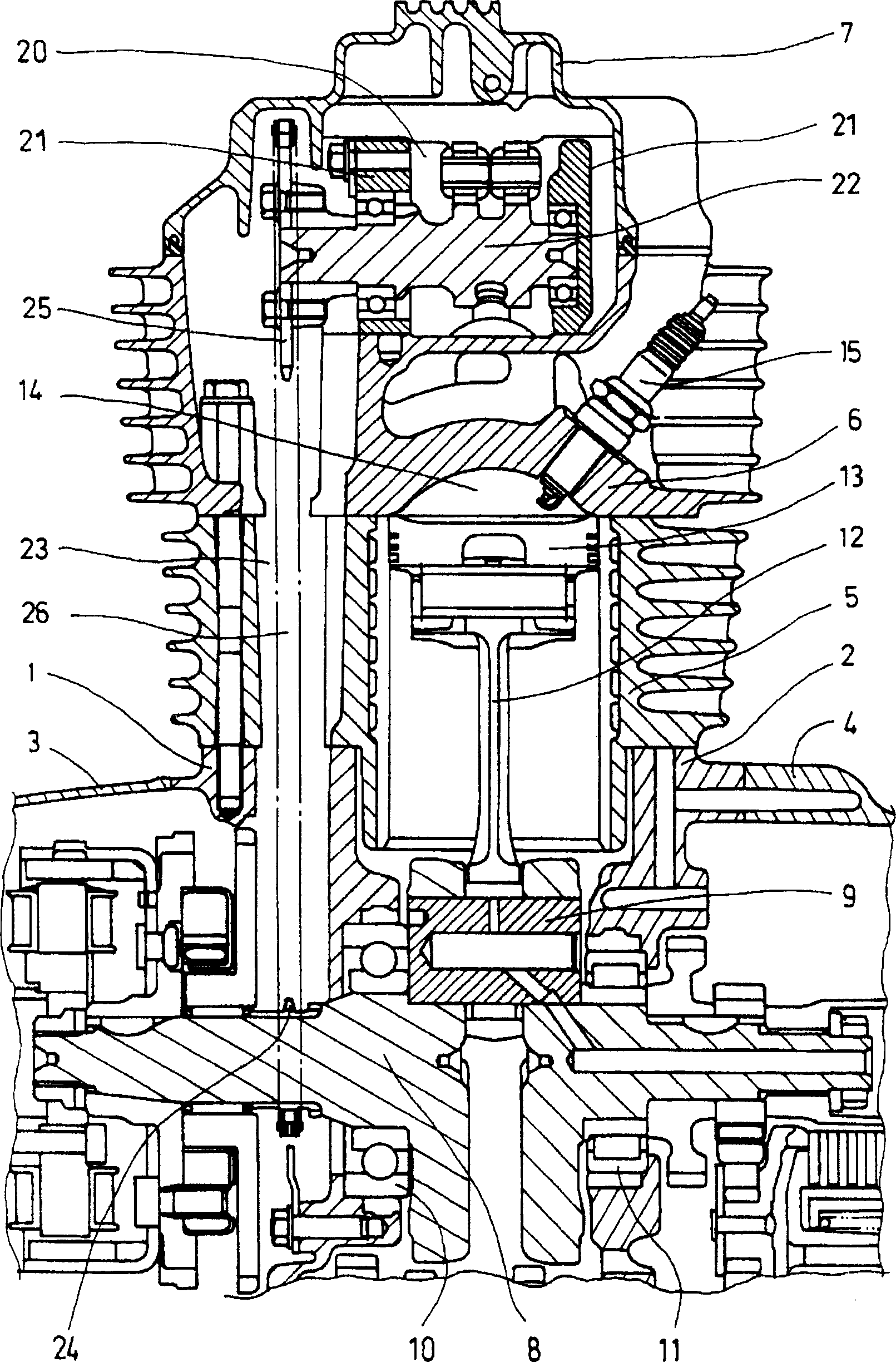

[0022] figure 1 It is a cross-sectional view of an OHC type single-cylinder internal combustion engine for a two-wheeled motorcycle according to an embodiment of the present invention from behind. The shell of this internal combustion engine among the figure is made of left crankcase 1, right crankcase 2, left crankcase cover 3, right crankcase cover 4, cylinder block 5, cylinder head 6, cylinder head cover 7. The crankshaft 8 is integrally formed of left and right parts with crank pins 9 . The crankshaft 8 is rotatably supported on the left crankcase 1 and the right crankcase 2 via rolling bearings 10 , 11 , respectively. The piston 13 is connected to the crank pin 9 via the connecting rod 12 and moves up and down in the cylinder block 5 . A combustion chamber 14 is formed under the cylinder head 6 . The ignition spark plug 15 is mounted on the cylinder head 6 with its front end facing the combustion chamber 14 .

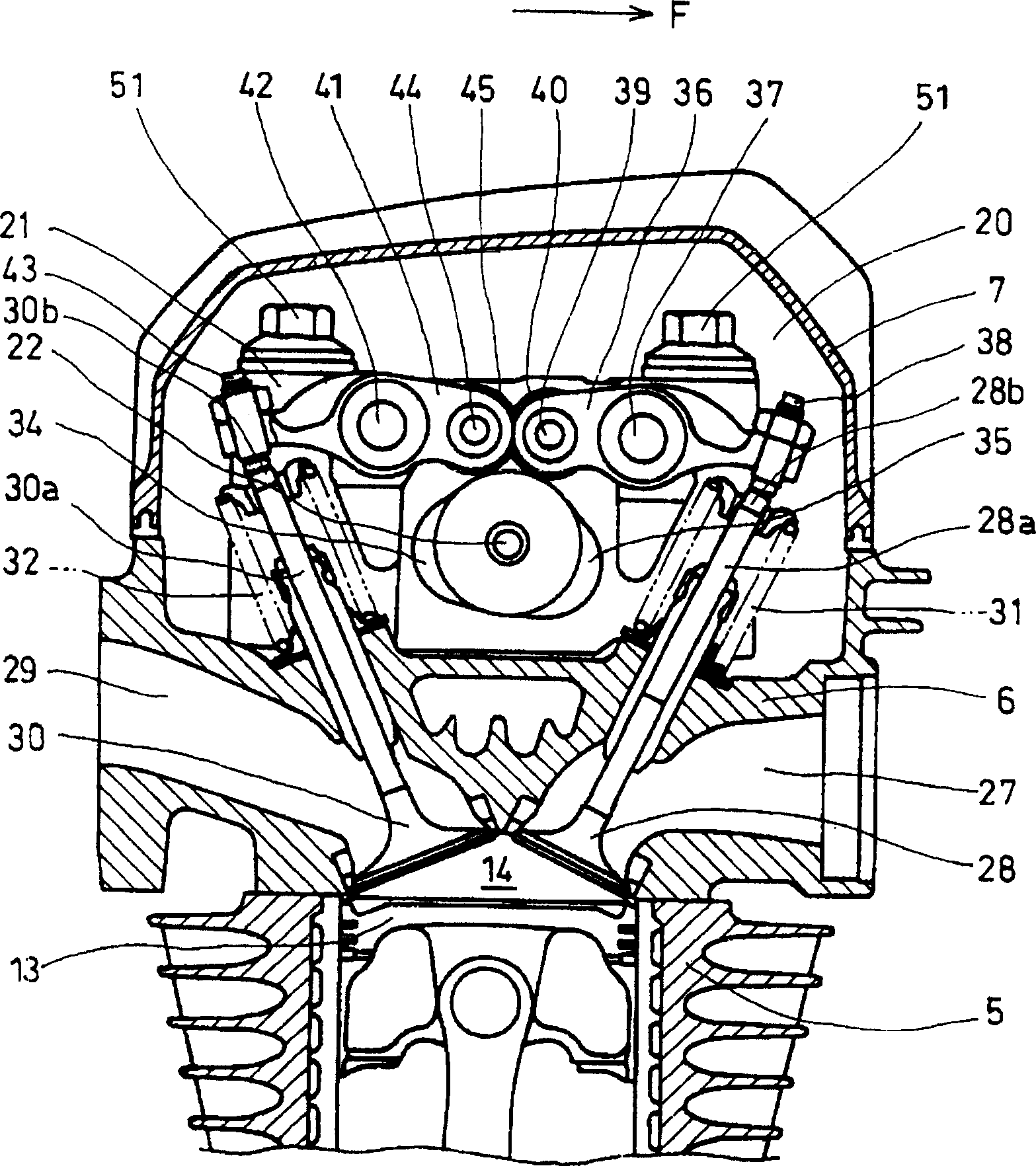

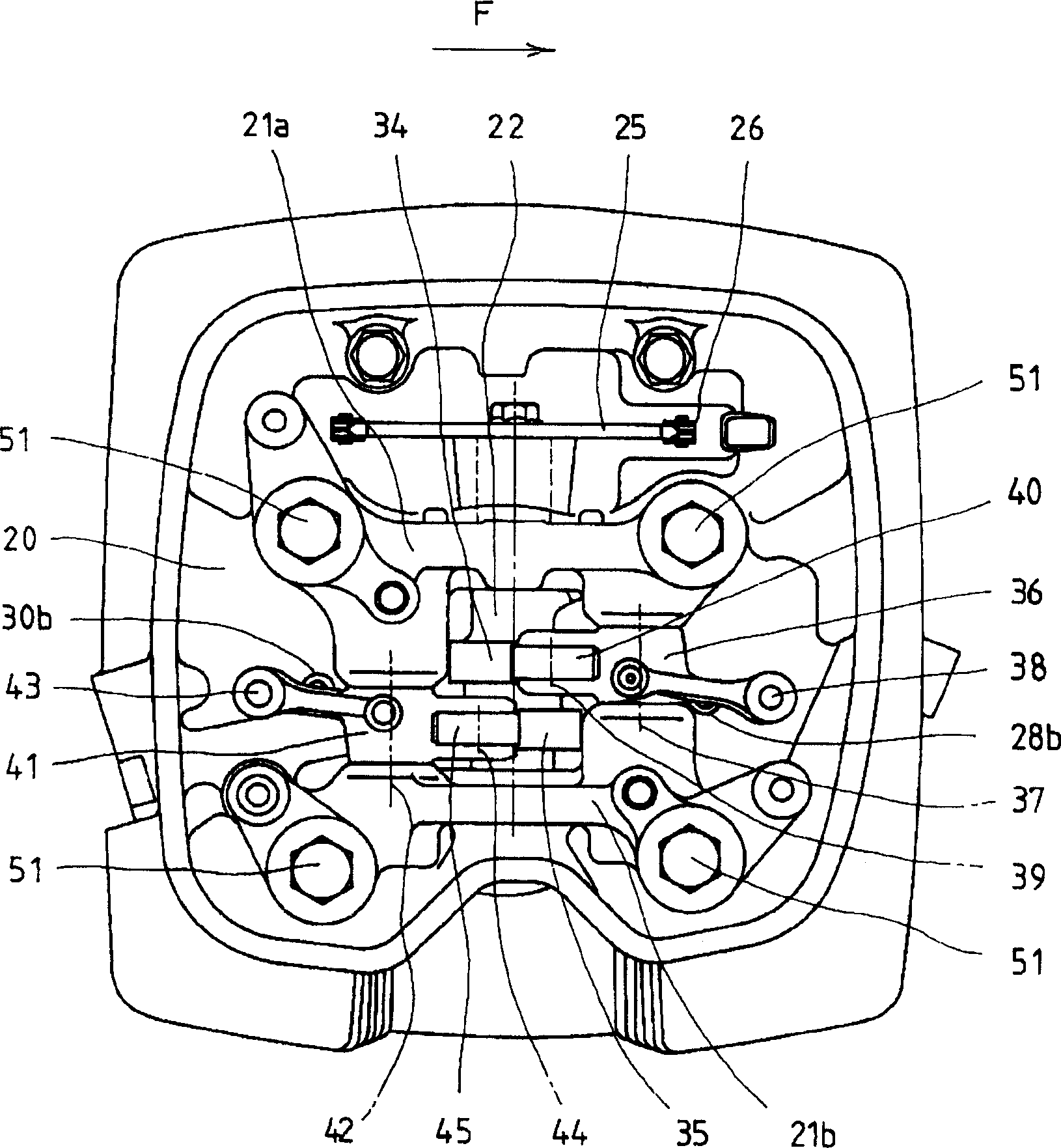

[0023] A camshaft 22 of the valve drive is mounted rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com