Timing chain of double VVT overhead camshaft engine for SUV and fabrication method

A camshaft and engine technology, applied in engine components, machines/engines, metal chains, etc., can solve problems such as low tensile strength, workpiece scratches, and scratch symmetry, improve impact resistance, and remove annular steps. , The effect of eliminating the stress concentration of annular cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

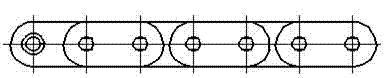

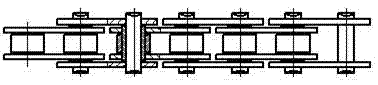

[0011] Embodiment 1: with reference to attached figure 2 with 3 . A double VVT overhead camshaft engine timing chain for SUV cars, the engine output maximum power 103KW, maximum torque 180N.m, maximum crankshaft sprocket speed 6000rpm, camshaft compression torque 28N. Tensile strength ≥ 10KN, circumferential tension ≤ 1650N; (2) The diameter of the arc at both ends of the outer and inner chain plates in the timing system transmission chain is 7.6max, and the chain plates of the outer and inner chain links Two chain pin shaft holes are respectively provided on the top, and the distance between the holes is 8mm, and the inner distance between the two inner chain plates of the inner chain link is 4.6min. The increase rate of the two ends of the chain pin protruding from the outer chain plate of the outer chain link is not less than 3%, and the diameter after the increase is 3.14min; the length of the protruding part is 0.85min; the periphery of the enlarged part is angular ...

Embodiment 2

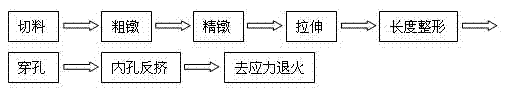

[0012] Embodiment 2: with reference to attached figure 1. A kind of manufacturing method of double VVT overhead camshaft engine timing chain for SUV automobile, the manufacturing method of the roller in the transmission chain of described timing system is as follows: (1) take materials: get 42CRrMo of Φ5.9mm, cut 3.05mm thick; (2) thick Upsetting: In the rough mold, the 42CRrMo with a thickness of 3.05mm and Φ5.9mm is upset to a thickness of 3mm, the upper Φ6.21mm, and the middle part of the arc edge around the lower part is Φ4mm; Upsetting is 3.03mm thick, upper Φ6.29mm, and middle part of the arc edge around the lower part is Φ4mm; (4) Stretching: In the drawing die, the roller material after fine heading is stretched to an outer diameter of Φ6.32mm, an inner diameter of Φ4.83mm, Height 5.65mm + 0 or 0.05; (5) Length shaping: the stretched roller material is shaped in the shaping mold, the outer diameter of the shaped roller material is Φ6.35mm, and the height is 5.62mm-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc diameter | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com