Engine cam shaft bearing frame

A technology of cam bearings and camshafts, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of single function, difficulty in ensuring reliability requirements, and the high-speed adaptability of push-and-rock valve mechanism is not as good as that of double overhead mechanism and other problems, to meet the requirements of high-speed use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

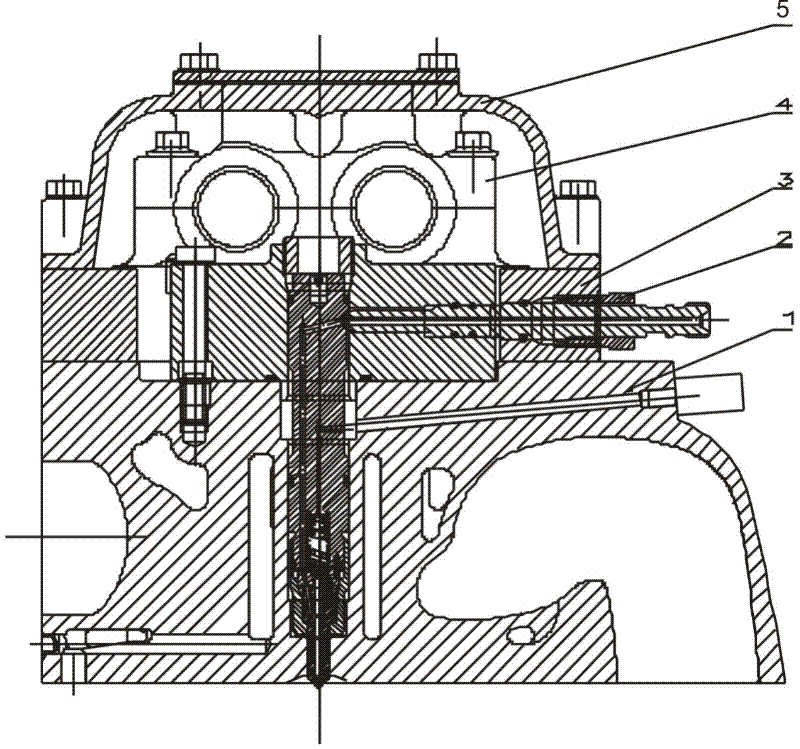

[0019] The engine camshaft bearing frame is composed of a camshaft frame body 3 and a cam bearing cover 4. The cam bearing cover 3 is fastened to the camshaft frame body 4 by bolts. The camshaft frame body 3 is provided with a valve chamber cover 5 and an injector The screw sleeve 2 is compressed, and the camshaft bearing frame is installed on the cylinder head 1.

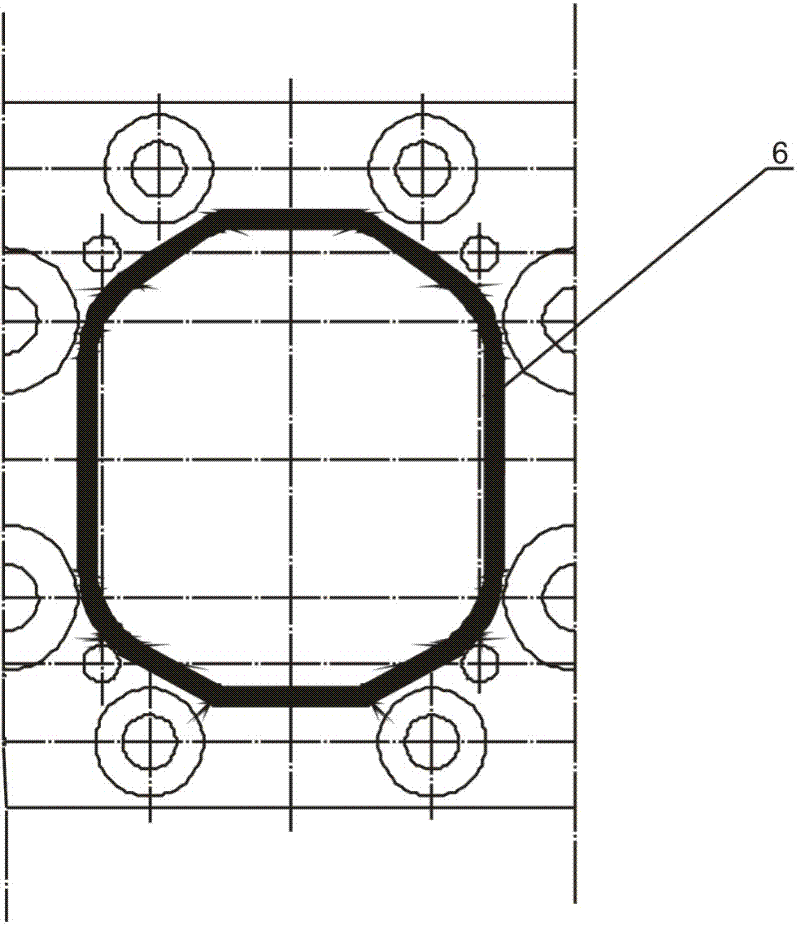

[0020] In order to realize the sealing of the lubricating oil of the single cylinder, a sealing band 6 is provided on the contact surface of the camshaft frame body 3 and the cylinder head 1. Glue can be applied to the sealing belt area to realize the direct contact and seal between the frame and the cylinder head, without the need for sealing gaskets and other structures to ensure the center position of the transmission after the camshaft is installed.

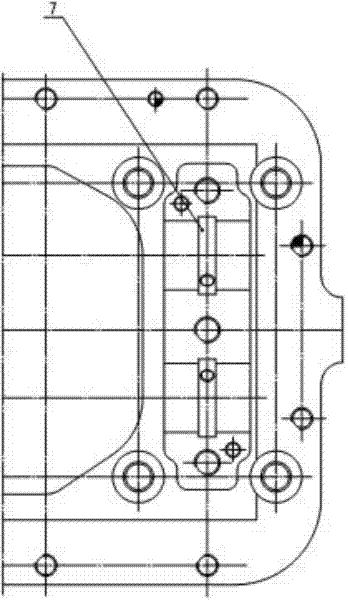

[0021] An oil reservoir 7 and an oil hole 8 are provided at the front ends of the camshaft frame body 3 and the cam bearing cover 4.

[0022] A camshaft thrust surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com