Neodymium-iron-boron bonded magnet, preparation method thereof and motor

A bonded magnet, NdFeB technology, used in magnetic objects, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problem that the strength cannot meet the high-speed use requirements of the motor, and achieve high-speed use and good dispersion uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

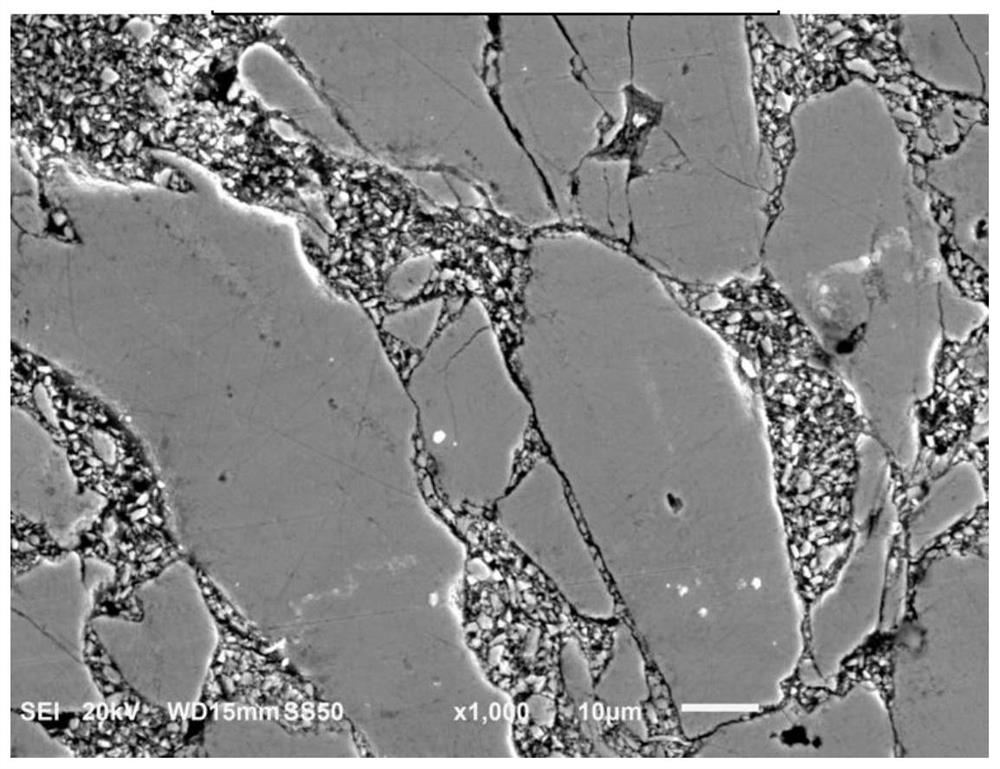

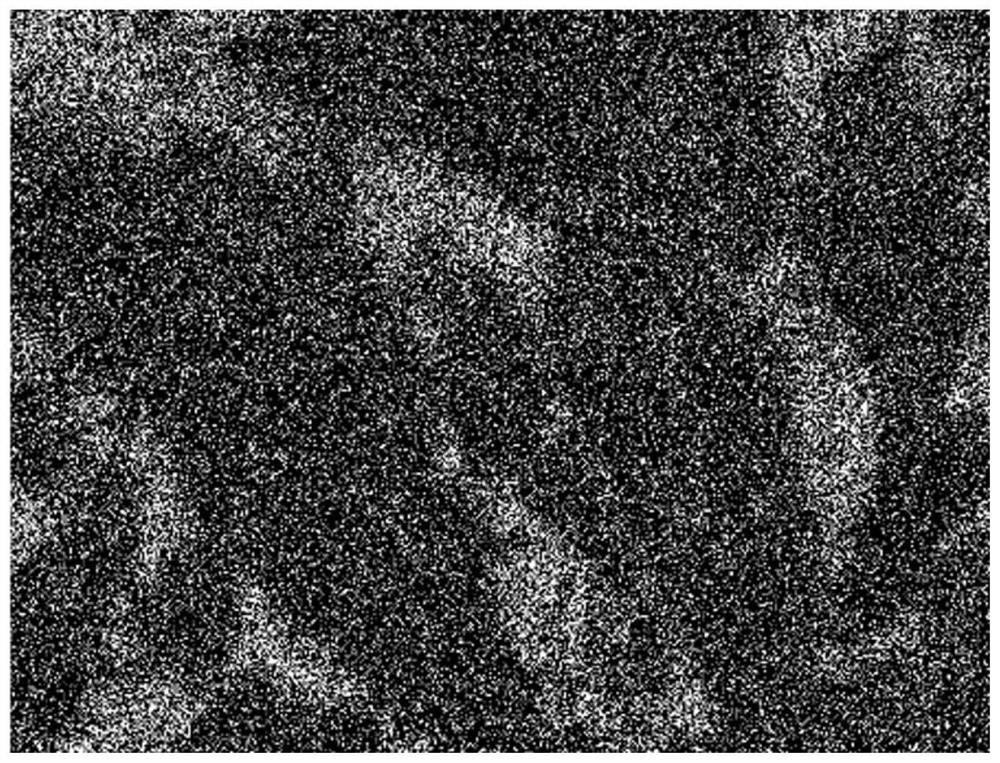

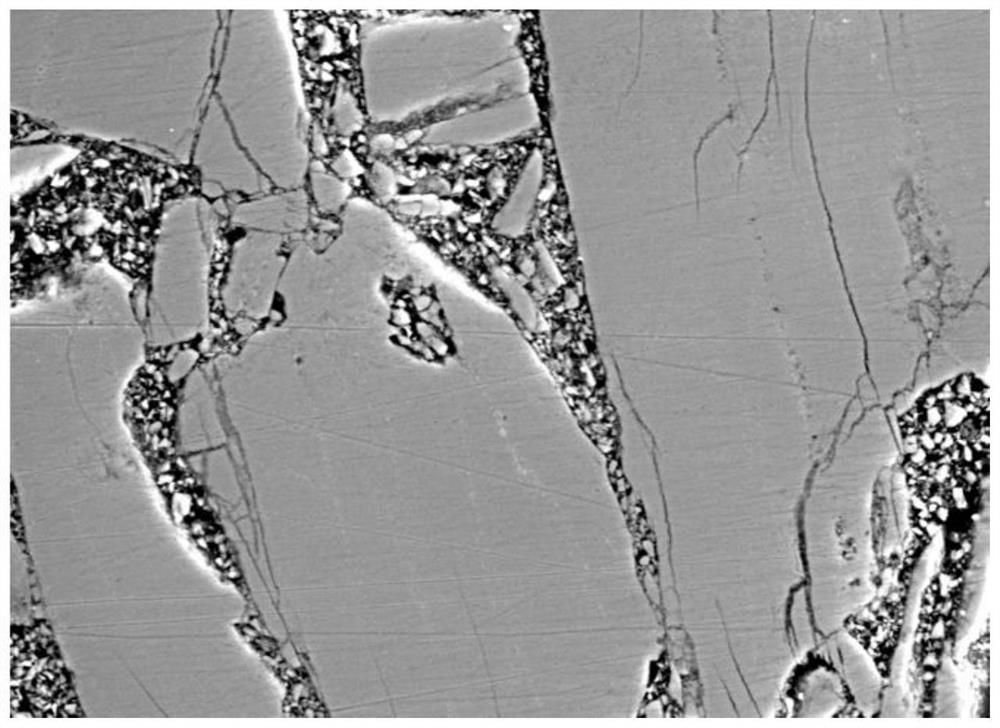

Image

Examples

preparation example Construction

[0025] In a typical embodiment of the application, a preparation method of NdFeB bonded magnet is provided, which comprises the following steps: S1, mixing phenolic resin, curing agent and NdFeB magnetic powder under heating conditions to obtain mixed rubber powder; S2, mixing the rubber powder and lubricant, and pressing to obtain a magnet compact, wherein the content of phenolic resin, curing agent, NdFeB magnetic powder and lubricant in the magnet compact is 2.5-6.0 wt%, 0.25-0.6 wt%, 93.3~97.15wt%% and 0.1-0.2 wt%, respectively; S3, performing sectional heating and curing on the magnet compact to obtain the NdFeB bonded magnet, wherein the sectional heating and curing is 2 to 4 sections of step-by-step heating and curing, the temperature of the sectional heating and curing is 105 to 195 DEG C, and the time is 30 to 60 minutes.

[0026] In this application, when mixing phenolic resin, curing agent and NdFeB magnetic powder, the heating and smelting method is adopted, which is d...

Embodiment 1

[0047] Mixing phenolic resin, curing agent and NdFeB magnetic powder in a reciprocating mixer at 95-105℃ for 30min to obtain mixed rubber; The mixed rubber and lubricant are mixed and pressed to obtain a magnet compact, and the pressing pressure is 10 tons / cm. 2 The types and contents of phenolic resin, curing agent, NdFeB magnetic powder and lubricant in magnet compacts are recorded in Table 1, and the internal mixing process and magnet manufacturing process are recorded in Table 2. Heating and curing the magnet compacts in sections to obtain NdFeB bonded magnets. The heating and curing steps are as follows: curing at 110℃ for 10min, curing at 130℃ for 10min, curing at 160℃ for 10min and curing at 190℃ for 10min, and the heating rate is 8℃ / min. Polyamide wax was purchased from Sentuo, Anhui.

[0048] The flow and process conditions of Examples 2 to 8 are the same as those of Example 1.

Embodiment 9

[0050] Mixing phenolic resin, curing agent and NdFeB magnetic powder in a reciprocating mixer at 70-80℃ for 30min to obtain mixed rubber powder; The rubber powder and lubricant are mixed and pressed to obtain a magnet compact, and the pressing pressure is 10 tons / cm. 2The composition of the magnet compact is the same as that of Example 2; Heating and curing the magnet compacts in sections to obtain NdFeB bonded magnets. The heating and curing steps are as follows: curing at 110℃ for 10min, curing at 130℃ for 10min, curing at 160℃ for 10min and curing at 190℃ for 10min, and the heating rate is 8℃ / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com