Two-stage variable compression ratio system of gasoline engine and control method thereof

A control method and compression ratio technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high cost and impracticality, and achieve the effect of high power density, rapid change, and avoidance of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

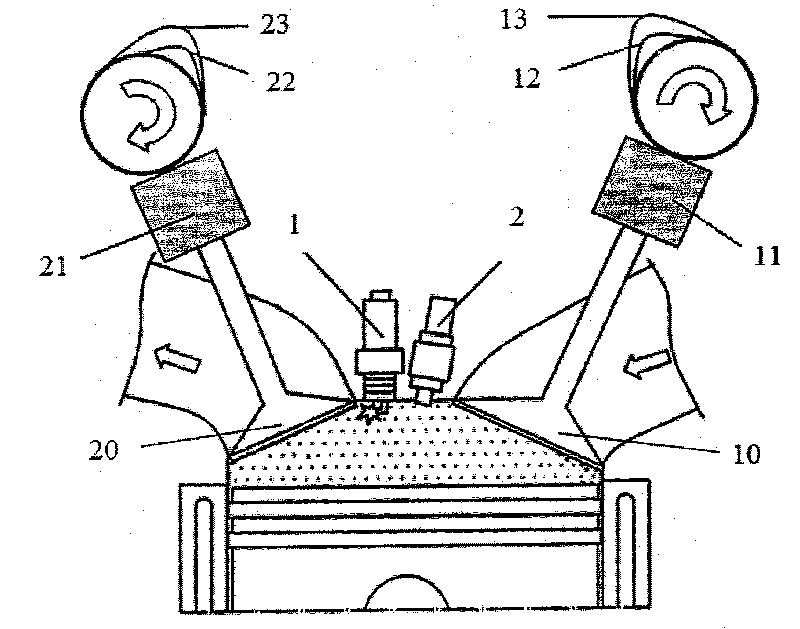

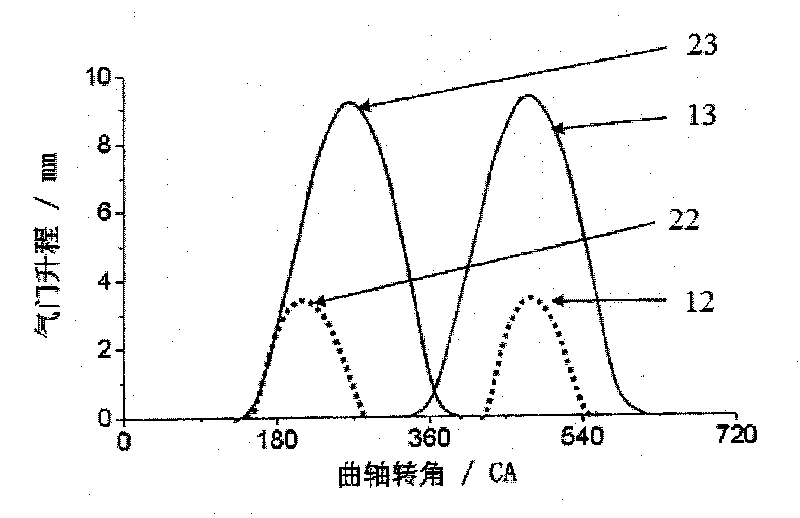

[0025] The gasoline engine two-stage variable compression ratio system of the present embodiment, such as figure 1 As shown, on the two overhead camshafts corresponding to the intake valve and exhaust valve of the engine, the intake valve 10 and the exhaust valve 20 of each cylinder are respectively provided with a large cam and a small cam; 10 is provided with an intake valve cam profile switching mechanism 11 for switching the intake valve large cam 13 and intake valve small cam 12 corresponding to the intake valve 10; The valve cam profile switching mechanism 21 is used for switching the large exhaust valve cam 23 and the small exhaust valve cam 22 corresponding to the exhaust valve 20 . figure 2 It is a schematic diagram of the above four kinds of cam lift curves.

[0026] The geometric compression ratio of the gasoline engine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com