Cam shaft and rocker shaft supporting seat of overhead cam shaft type engine

A technology of camshafts and support seats, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of increasing procedures and manufacturing costs, and achieve the effects of simplifying the manufacturing process, good lubrication and cooling effects, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

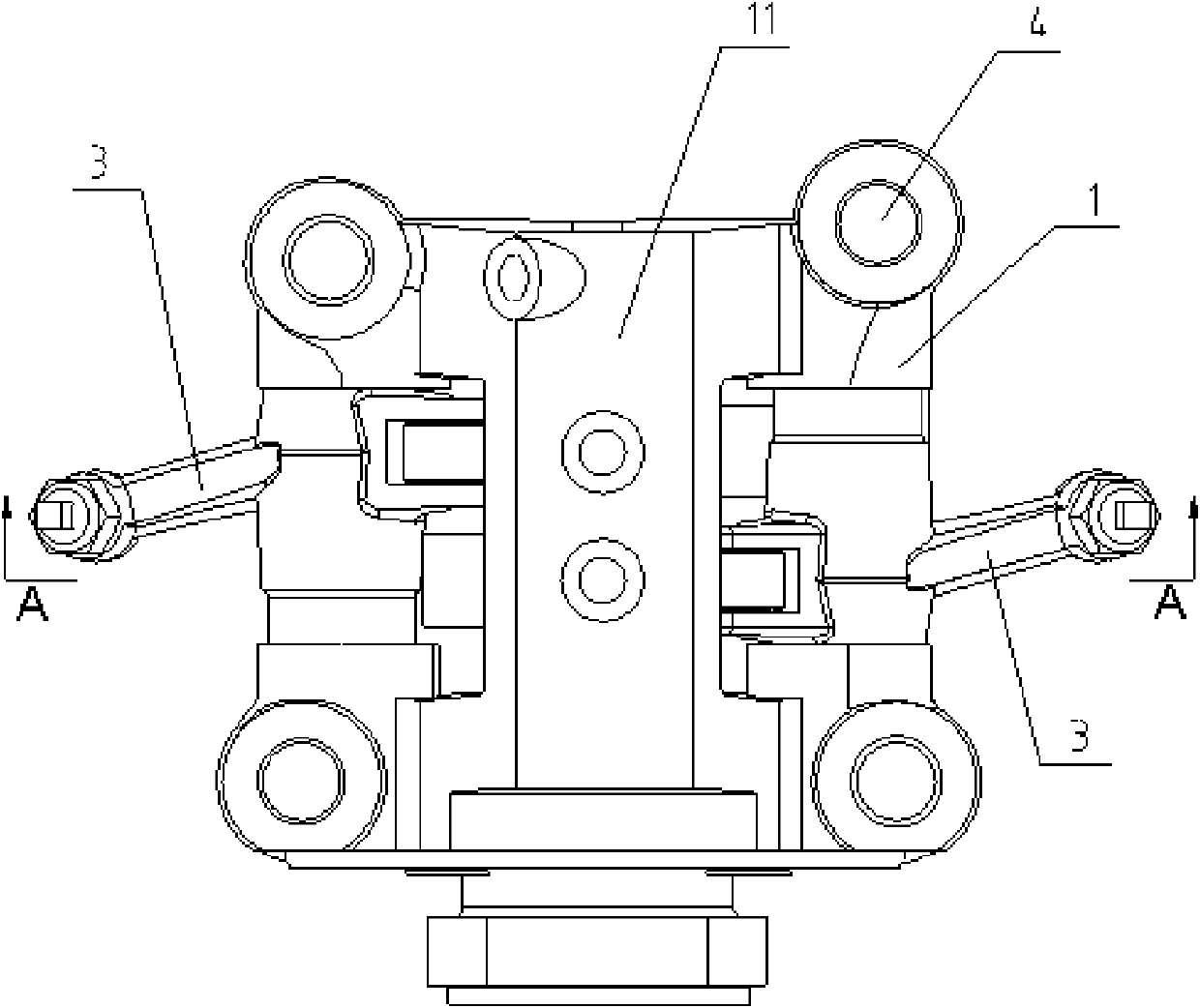

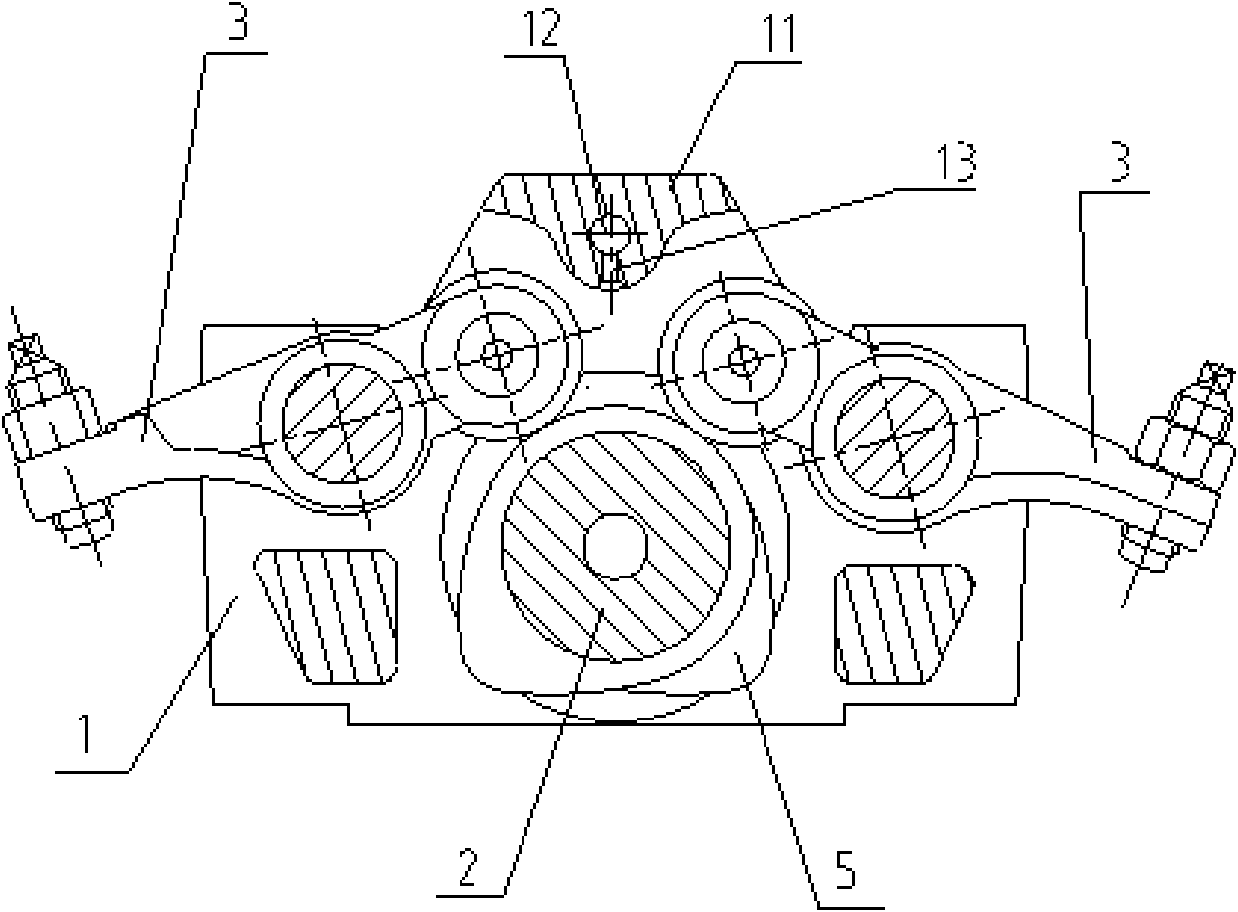

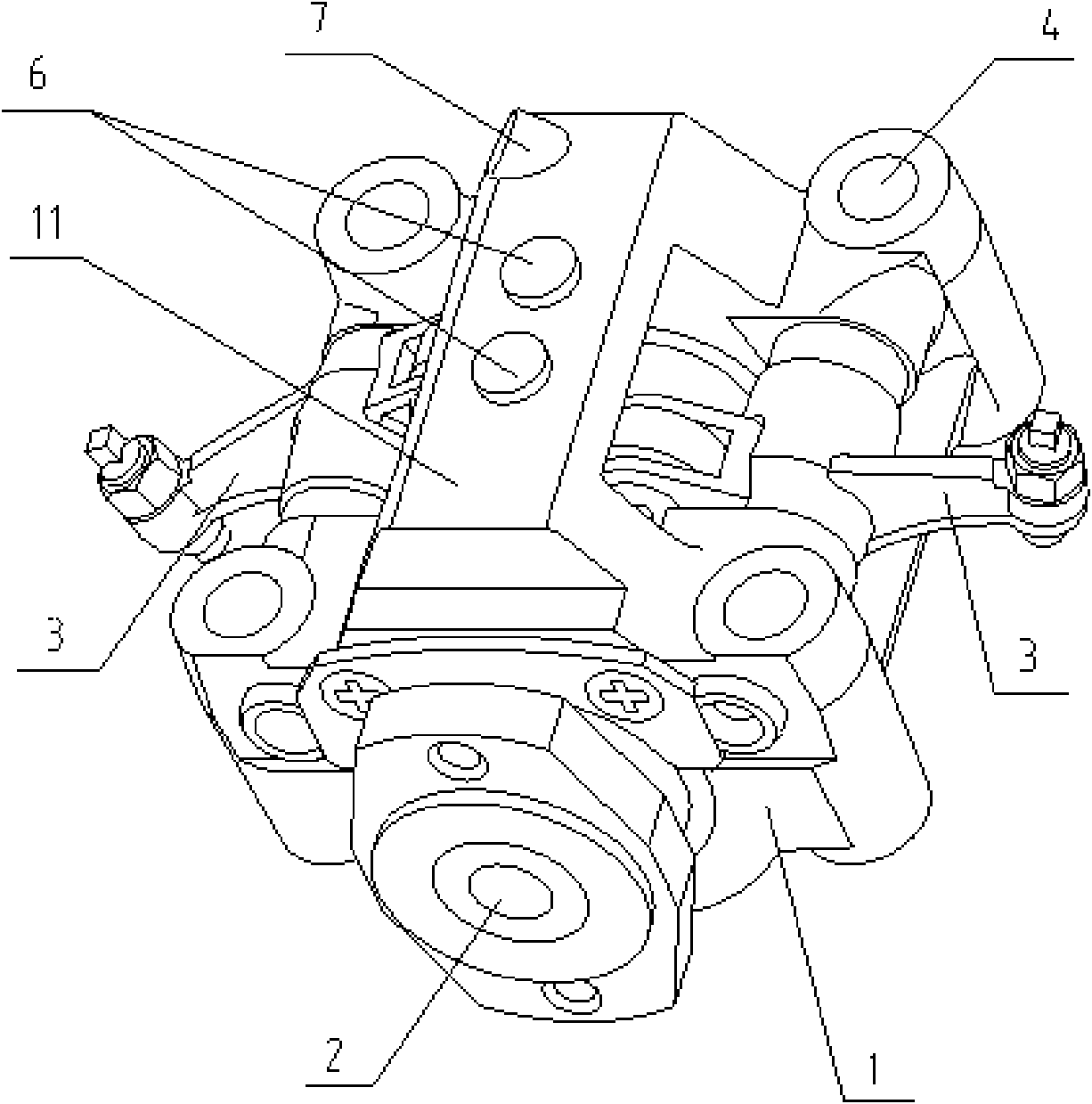

[0014] like Figure 1 to Figure 4 As shown, the camshaft and rocker shaft support seat of an overhead camshaft type engine, the camshaft 2 and the rocker arm 3 have been installed on the support seat 1, and the support seat 1 is independent of the cylinder head and the cylinder head. Integral forming member, rocker arm support seat holes and camshaft holes are provided on the support base 1, the bolt holes 4 at the four corners of the support base 1 correspond to the positions of the bolt holes on the cylinder head and the cylinder head, and the position of the bolt holes on the support base 1 The upper end surface of the upper end is integrally formed with a bridge-type connecting beam 11, and the connecting beam 11 is provided with a branch oil passage 12 and an oil injection hole 13, and the branch oil passage 12 communicates with the main oil passage on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com