Concentrator for vehicle

A technology for hubs and vehicles, applied in the direction of electrical components, etc., can solve problems such as difficult diagnosis, sockets detached from the sheet metal, and tight space in the car body, so as to improve the safety and durability of use, avoid mutual loosening, and simplify The effect of routing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

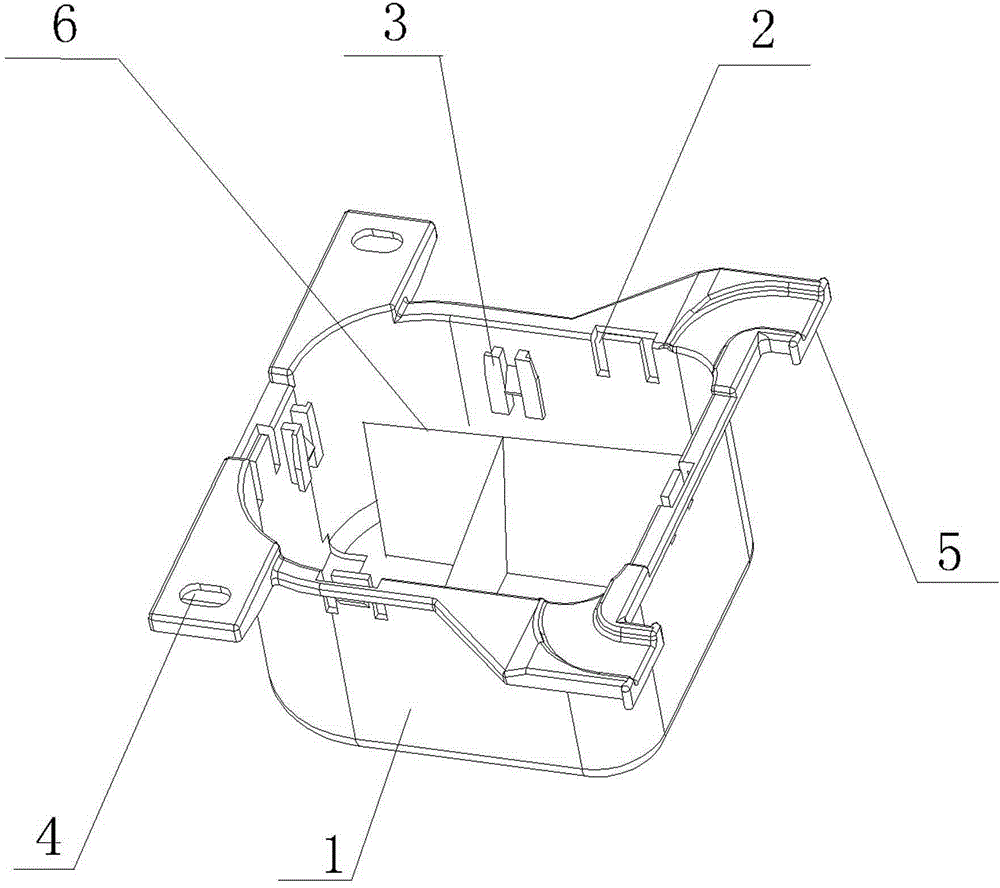

[0016] as attached figure 1 As shown, this embodiment includes a junction box main body 1, the junction box main body 1 is a box body with an open upper end, and two adjacent corners of the junction box main body 1 are provided with wire harness guide grooves 5, and the wire harness guide The groove 5 extends outwards at two corners of the main body of the junction box 1 and is arranged outwardly in an arc-shaped track. An ear is arranged on the outside, and positioning holes 4 for fixing the main body 1 of the junction box are arranged on the two ears. The inner edge of the main body 1 of the junction box is provided with a positioning buckle 2 for fixing the main body 1 of the junction box. The number of buckles 2 is 4, which are respectively arranged on the surrounding side walls of the main body 1 of the junction box, and the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com