Fixing structure of wire harness

A wire harness and structure technology, applied in clothing, fasteners, circuits or fluid pipelines, etc., can solve the problems of heavy workload, wire harness falling off, and increased cost, and achieve the effect of reducing cost, not easy to swing sound, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, the fixing structure of the wire harness of the present invention will be described with reference to the drawings.

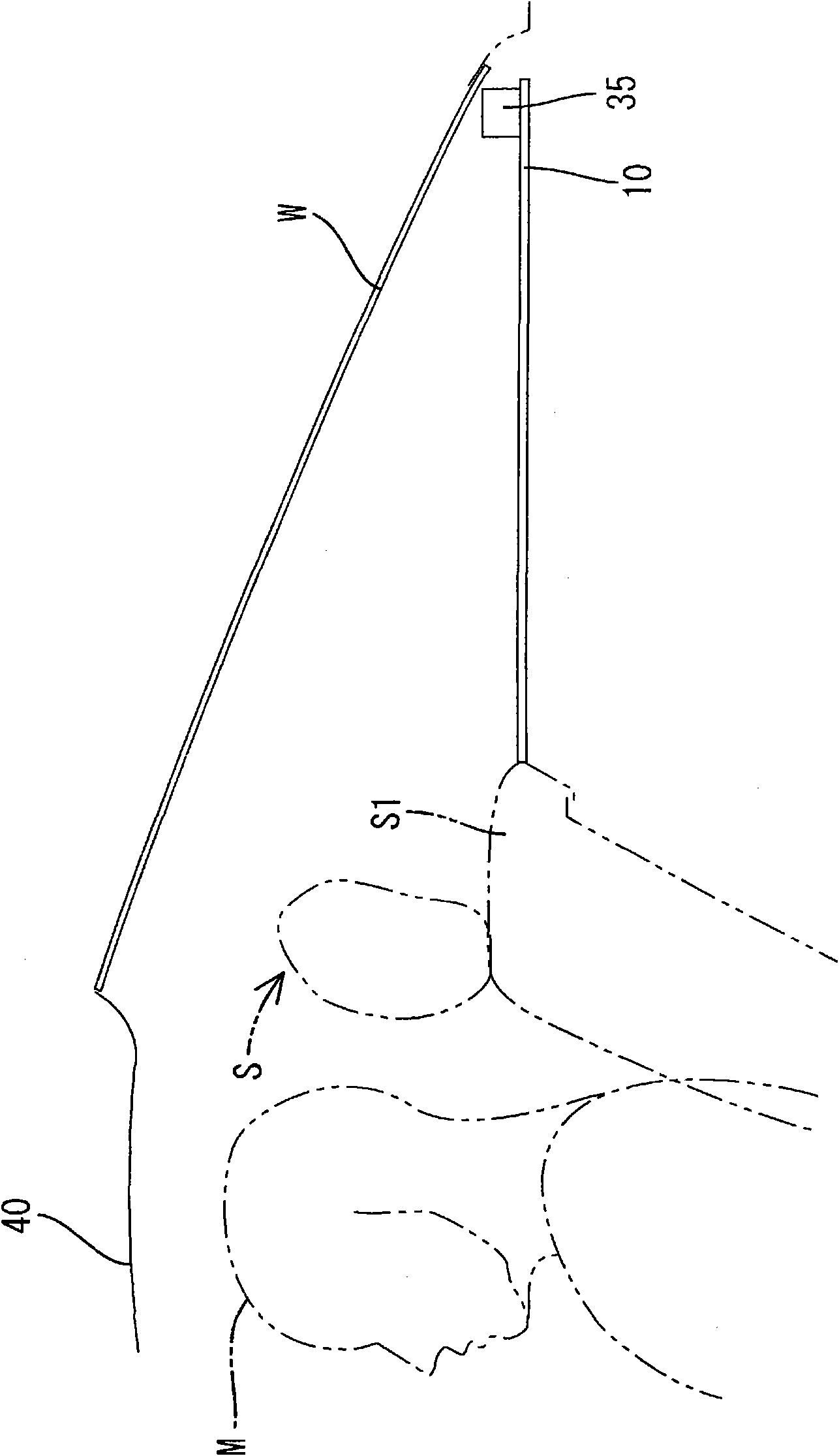

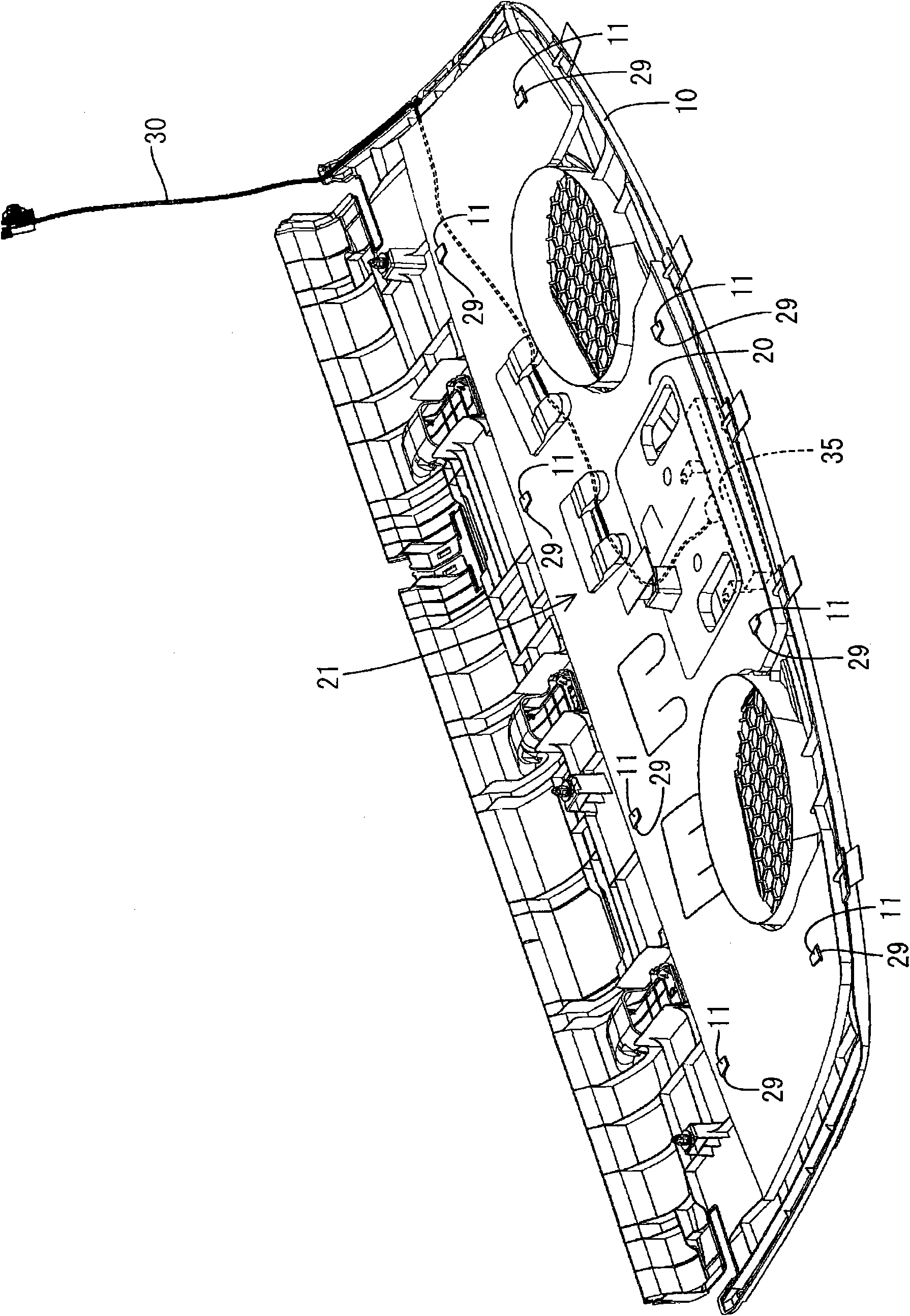

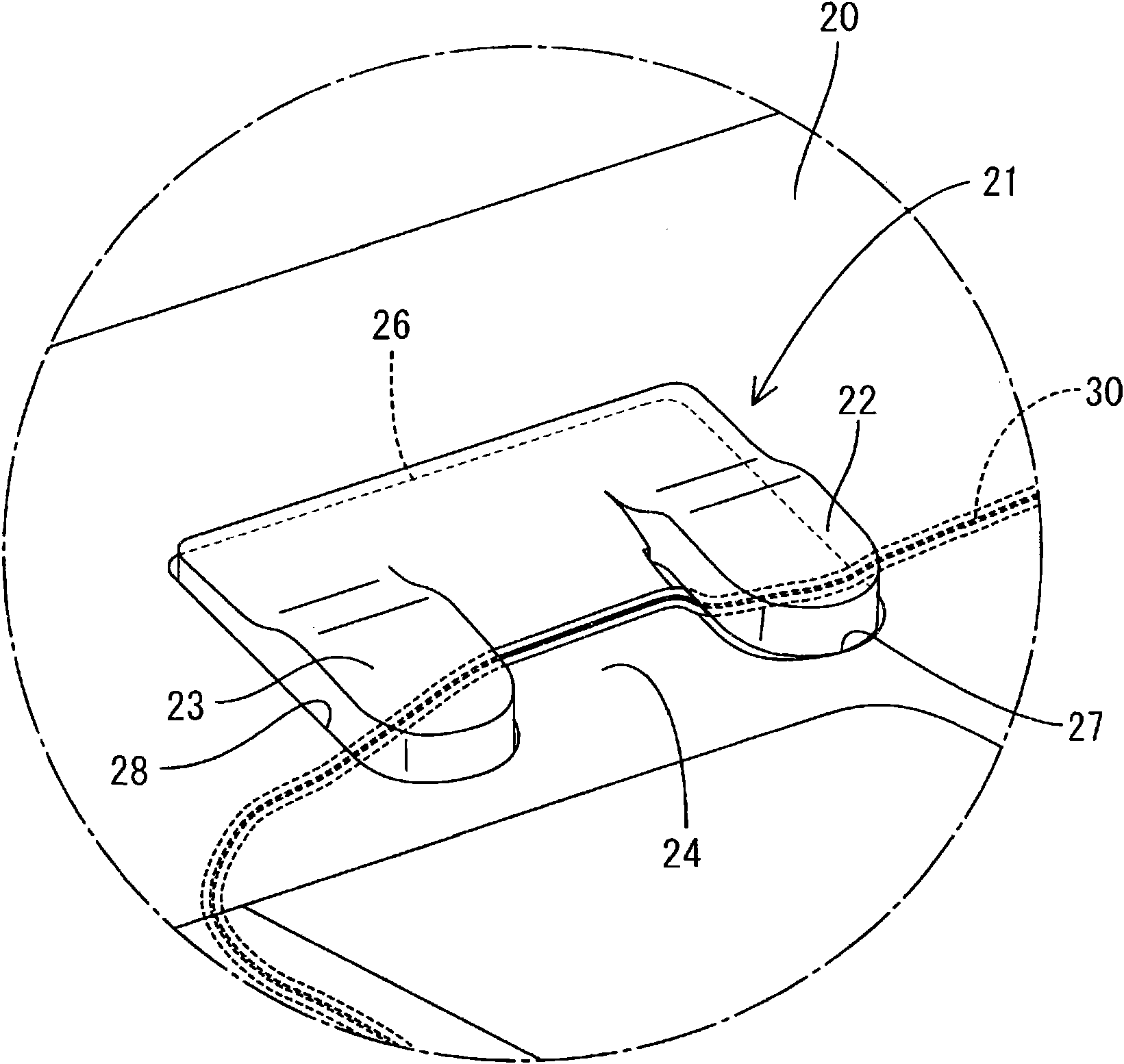

[0035] figure 1 It is an explanatory diagram showing the schematic structure of the rear side of the vehicle, figure 2 It is a perspective view showing the rear structure of a vehicle interior member (luggage shelf) including a fixing structure for a wire harness according to the present invention, image 3 It is an explanatory diagram showing the fixing structure of the harness on an enlarged scale, Figure 4 It is a plan view showing the arrangement position of the locking piece included in the fixing structure of the wire harness.

[0036] exist figure 1 Among them, a luggage shelf 10 as an interior part for a vehicle is arranged on the rear upper part of the seatback S1 of the rear seat S where the passenger M can be seated. Brake lights 35. On the other hand, below (inside) the luggage rack 10 such as figure 2 As shown, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com