Automobile left suspension bracket capable of fixing wiring harness holder

A left-mounted, fixed-line technology, applied in power units, vehicle components, jet propulsion units, etc., can solve the problems of increasing engine parts and increasing engine manufacturing costs, and achieve a simplified, compact structure and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

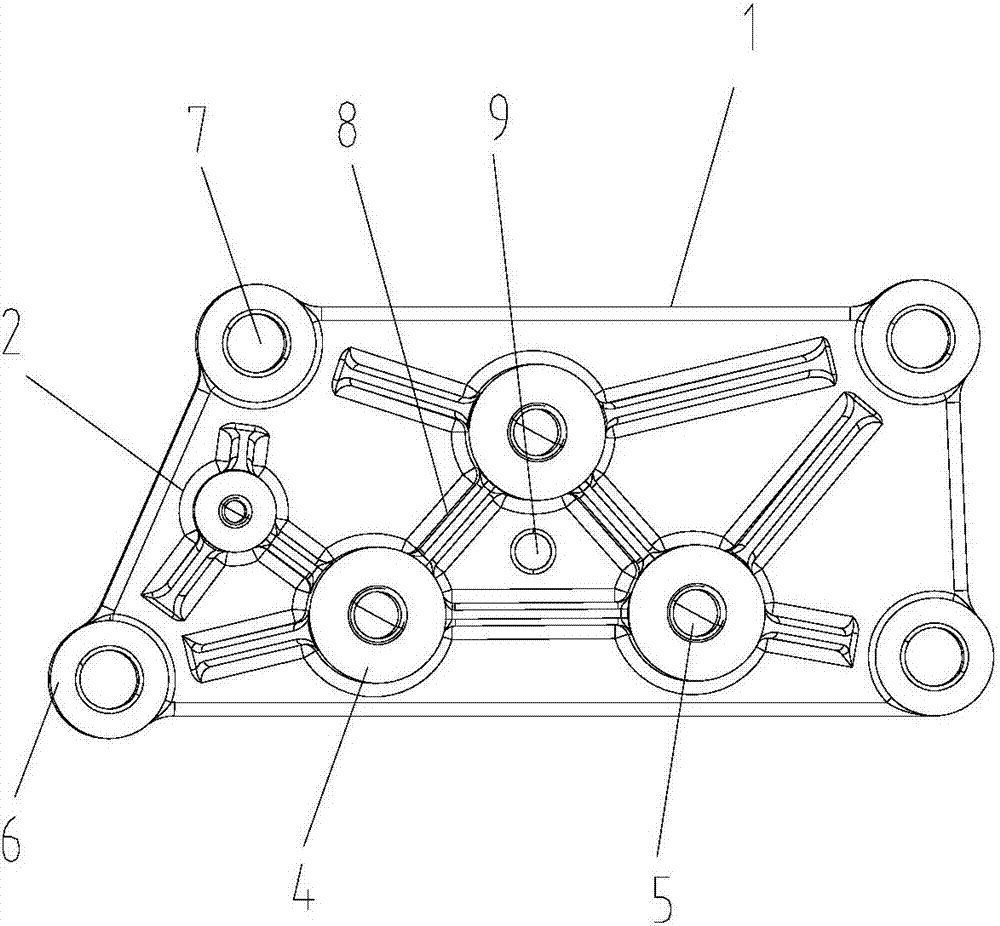

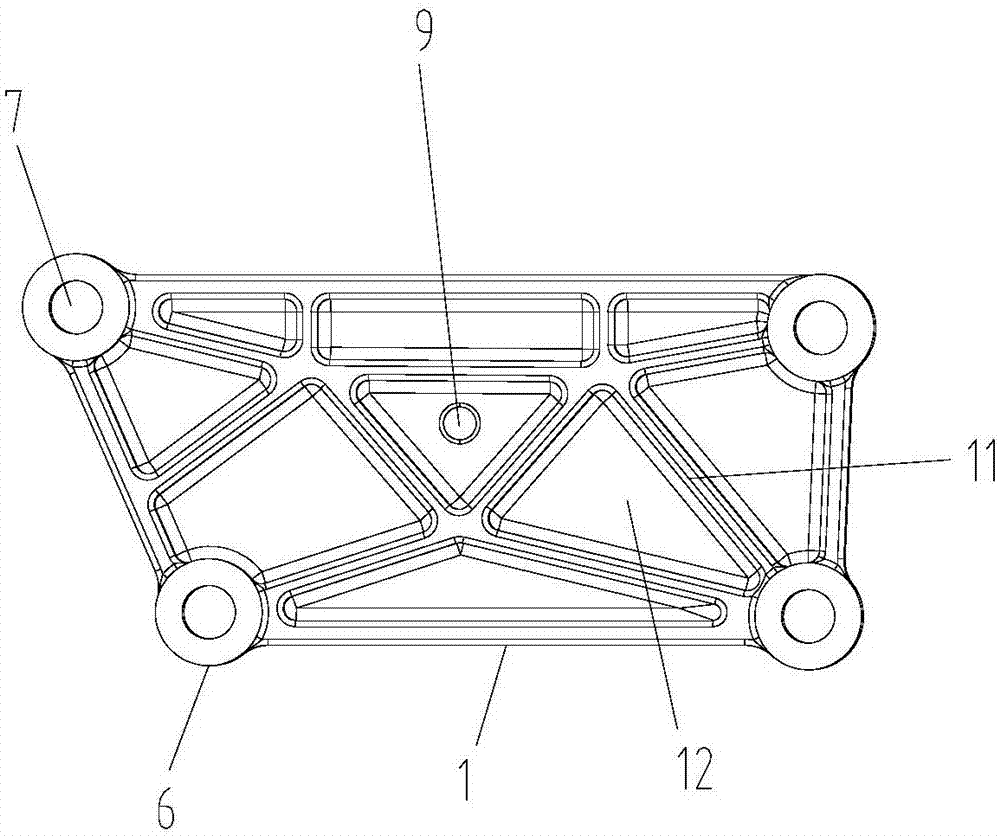

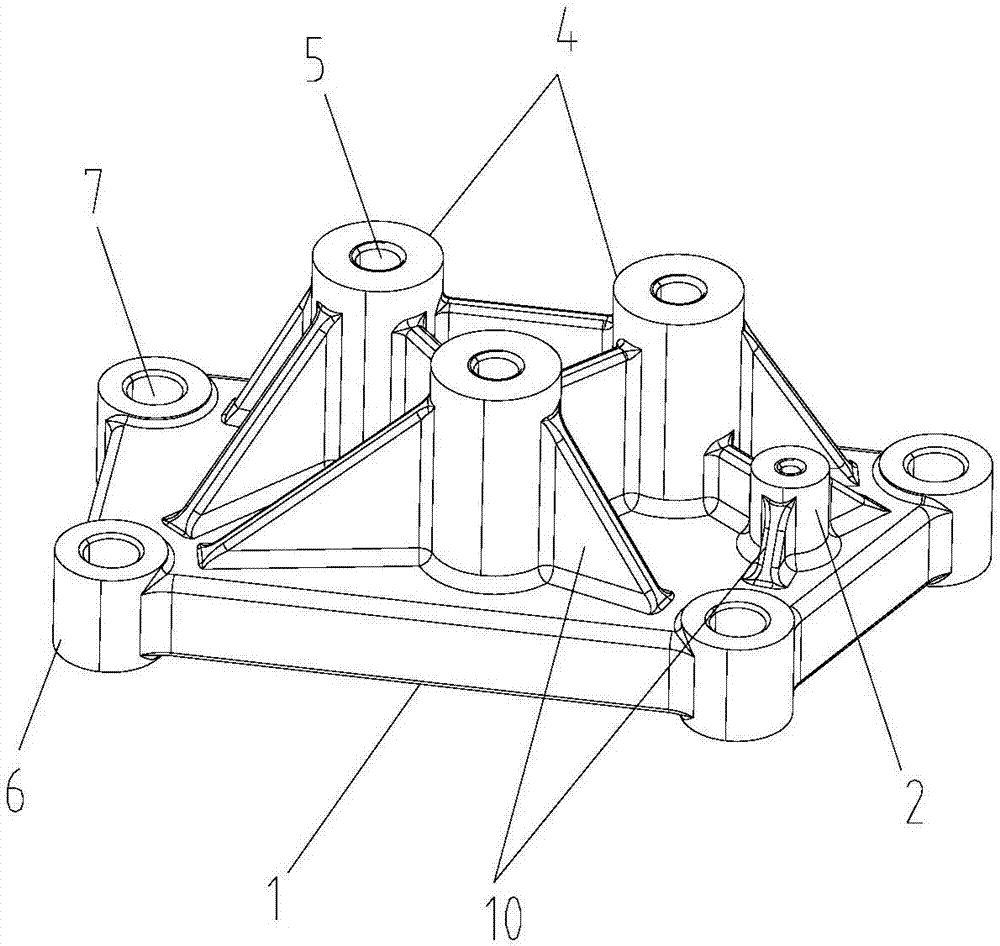

[0021] figure 1 It is a top view of the present invention, figure 2 It is a bottom view of the present invention, image 3 It is a schematic diagram of the three-dimensional structure of the present invention, as shown in the figure: the car left suspension bracket that can fix the wire harness bracket in this embodiment includes a supporting plate 1, and the supporting plate 1 is provided with an engine connection part for connecting with the engine And the cushion connection part used to connect with the left suspension cushion assembly, the harness bracket connection part used to connect the harness bracket is also provided on the said pallet 1; the bracket can be used to fix the harness bracket, the engine and the harness bracket The structure can be simplified, thereby effectively reducing the number of engine parts and making the engine structure more compact, which is conducive to the realization of automobile lightweight and reduces the manufacturing cost of the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com