Outer cover material for wire harness, and routing structure for wire harness

A wire harness and assembly technology, which is applied in the field of wiring structure of wire harnesses for sliding seats, can solve the problems of increased cost, installation space, interference of peripheral equipment, etc., and achieves the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

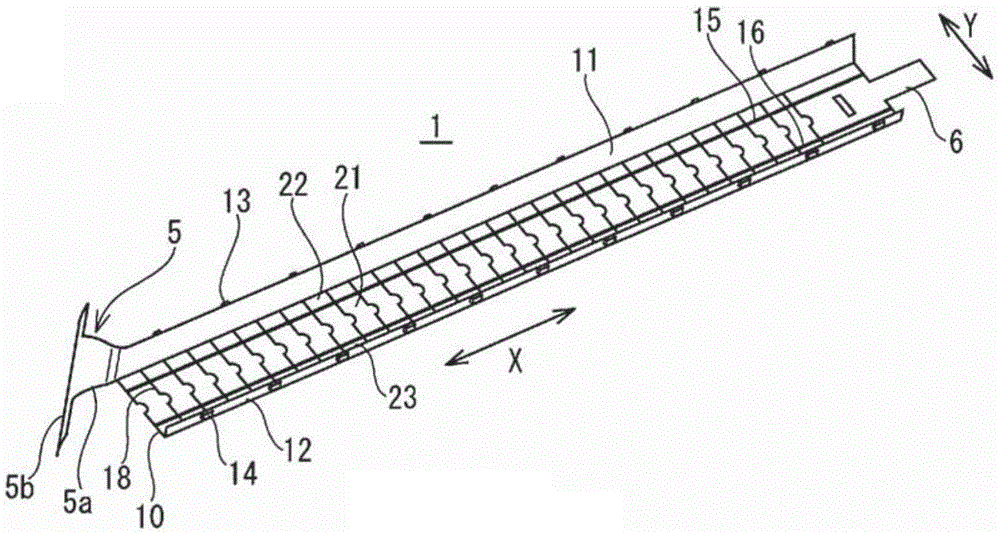

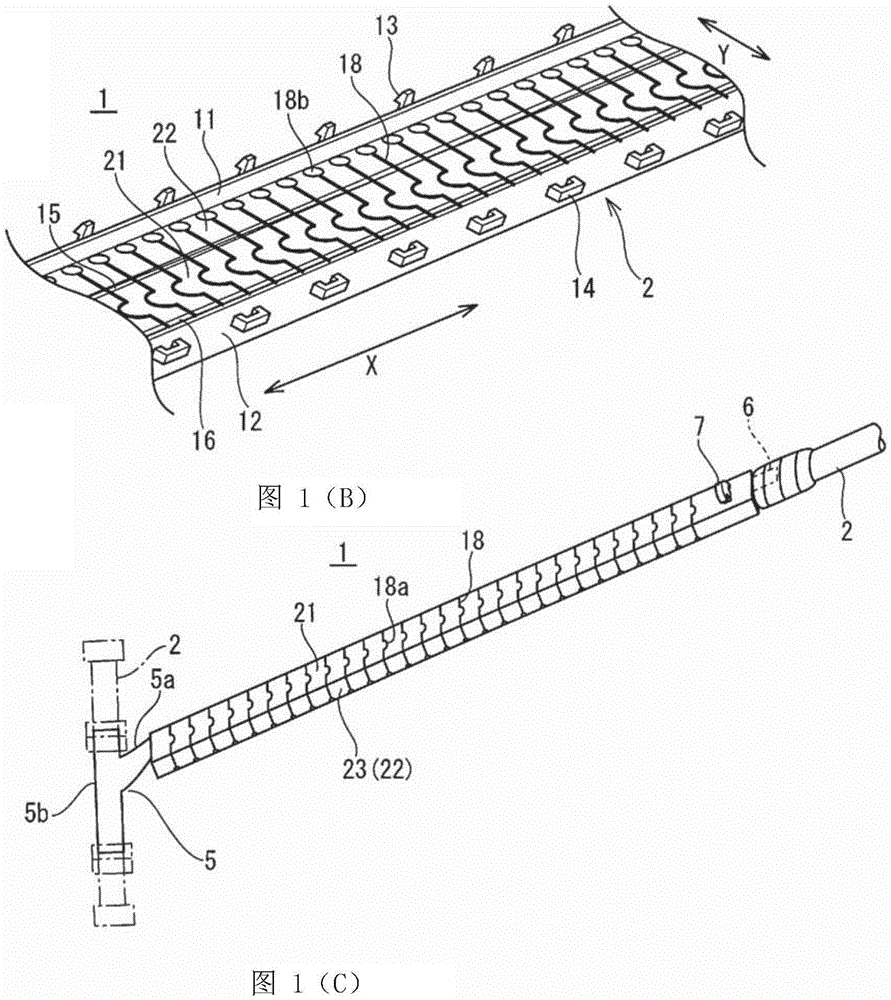

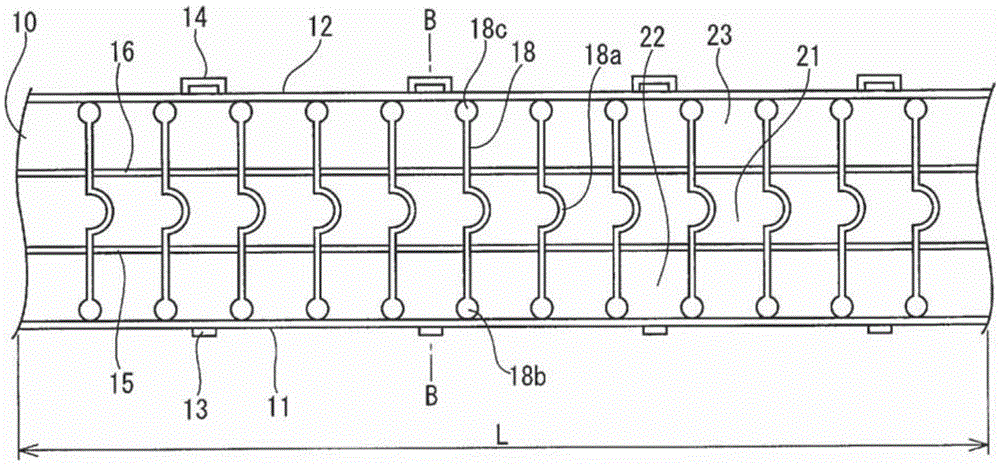

[0056] Embodiments of the present invention will be described below with reference to the drawings.

[0057] Embodiments of the exterior material for wire harnesses of the present invention are shown in FIGS. 1 to 3 .

[0058] The exterior material 1 shown in FIG. 1 and FIG. 2 is composed of an injection molded product, and is formed of polypropylene in this embodiment. The exterior material 1 is bent and assembled into a rectangular tube with the wire harness 2 attached thereto, and is of a caterpillar type that can be bent by opening and closing slits 18 provided at constant intervals in the longitudinal direction.

[0059] The exterior material 1 protrudes in parallel with a pair of joint plates 11 and 12 bent by approximately 90 degrees along both end edges in the width direction Y of the strip-shaped central plate 10 . At the top end of one joint plate 11, on the longitudinal direction X, a lock pawl 13 protrudes at a constant interval, on the other hand, a lock frame 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com