Device and method for sleeving wire harness with heat-shrinkable tube

A heat-shrinkable tube and wire harness technology, which is applied in the field of wire harness sleeve heat-shrinkable tube equipment, can solve the problems of time lag, poor coating quality, hot air without homogenization treatment, etc., and achieve uniform heating, good performance and smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

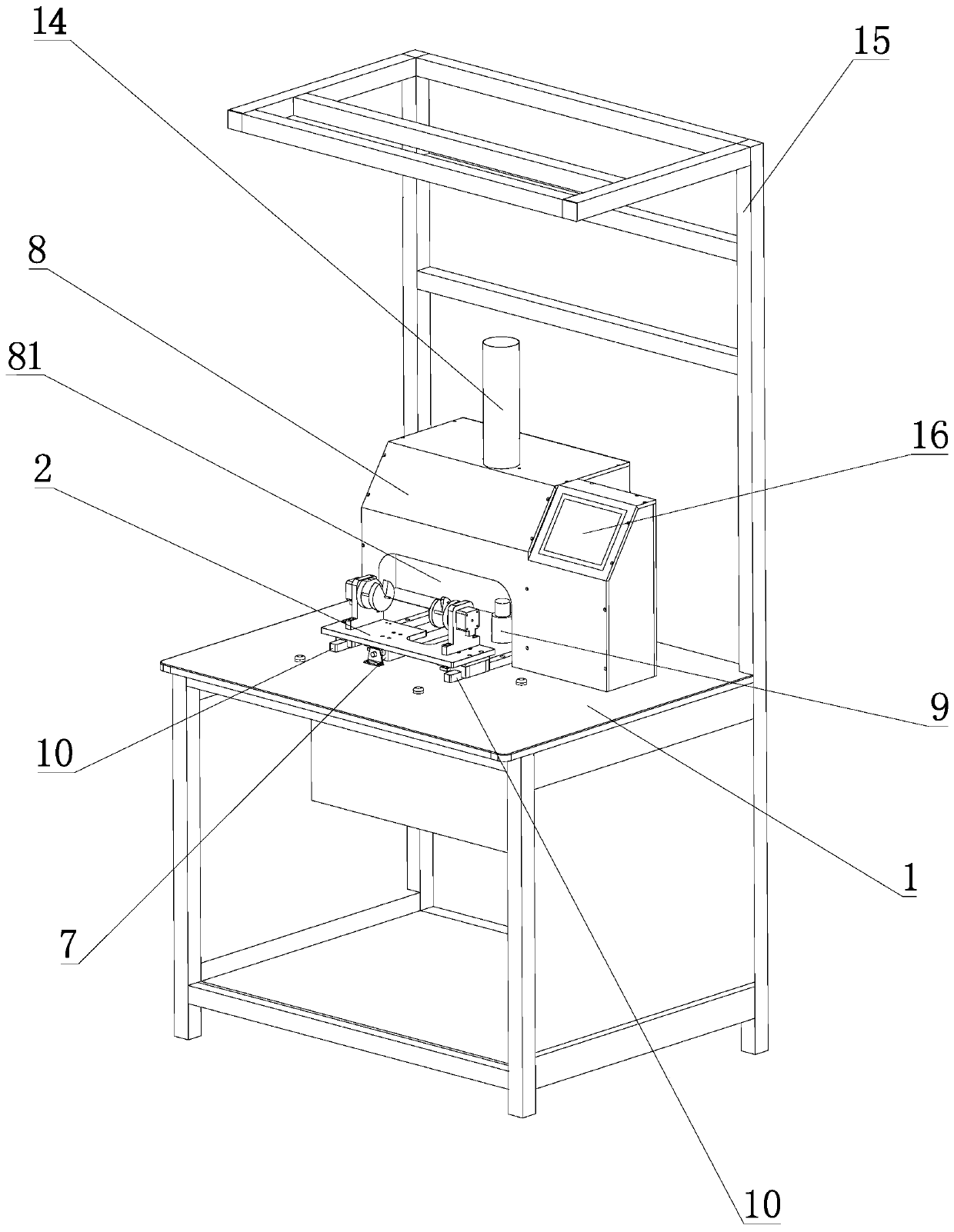

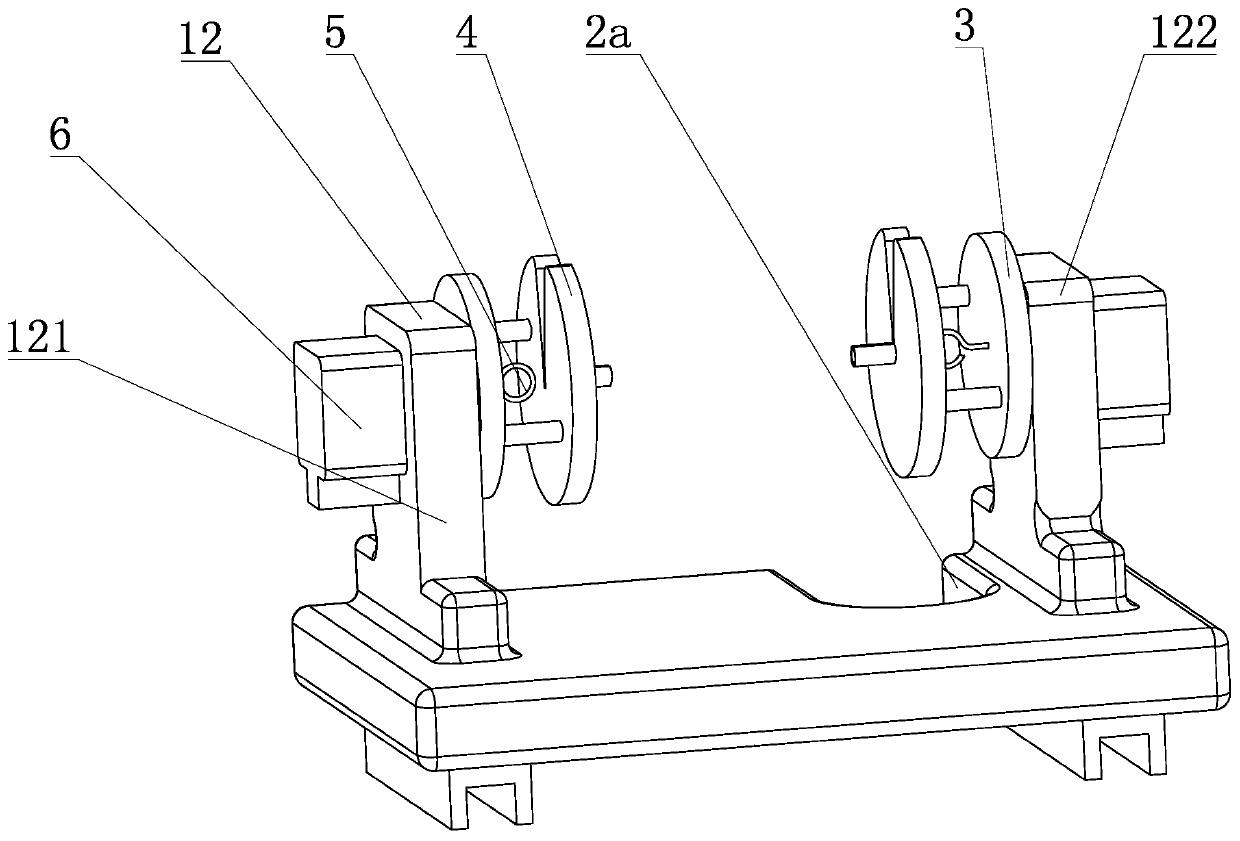

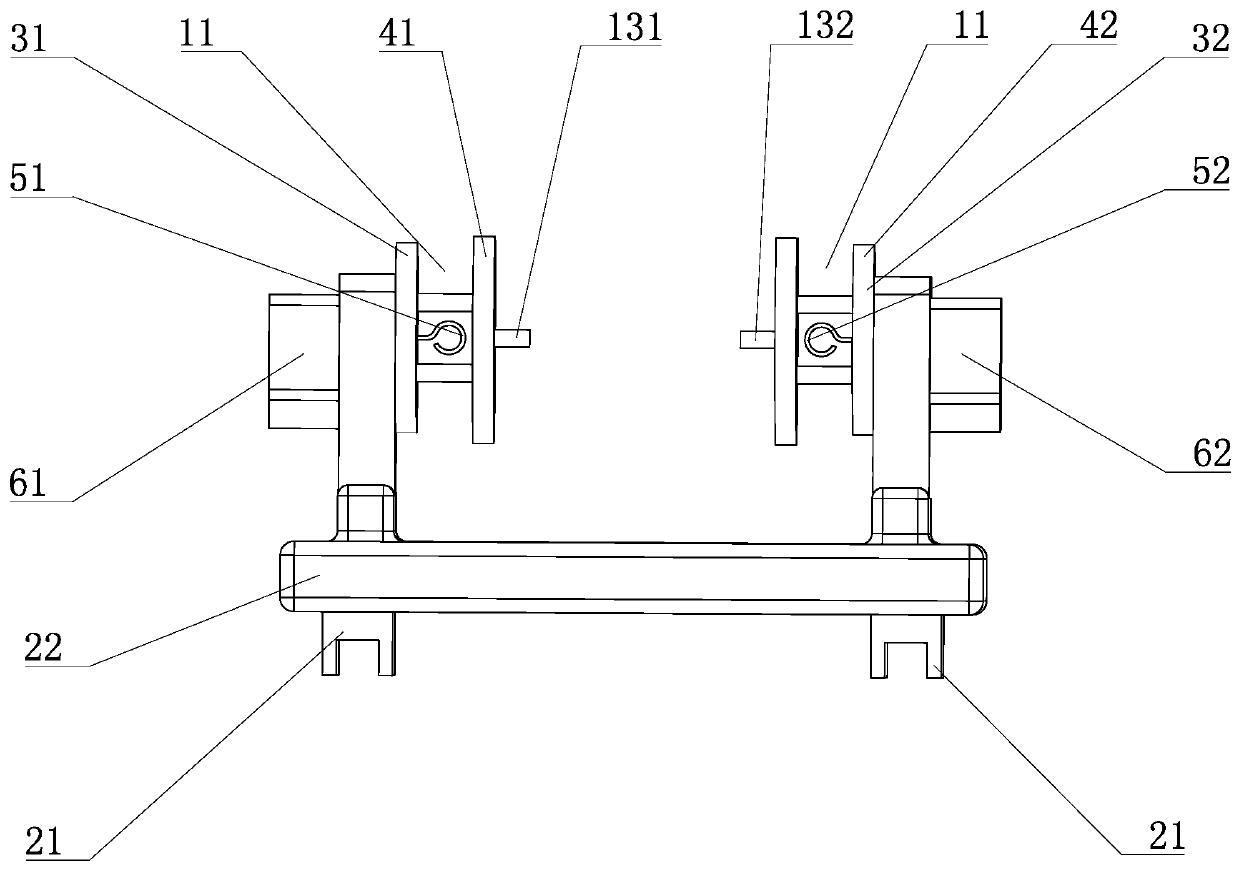

[0046] Such as Figure 1 to Figure 5 As shown, a frame 1 is included, and a mobile platform 2 is movably connected to the frame 1, and two rotating disks 3 are connected to the mobile platform 2, and the two rotating disks 3 are arranged in parallel and opposed to each other. A heat-shrinkable tube fixing block 4 for fixing the heat-shrinkable tube is fixedly connected to the two rotating disks 3 respectively, and the two heat-shrinkable tube fixing blocks 4 are arranged in parallel and opposite to each other. A wire harness fixer 5 for fixing the wire harness is connected, the rotating disc 3 is driven by a motor 6, and the frame 1 is equipped with a driving mechanism 7 for driving the mobile platform 2 to slide in and out of the heating box 8, The frame 1 is connected with a heat gun 9, the air outlet of the heat gun 9 is aligned with the gap between the two heat-shrinkable tube fixing blocks 4, and the heat gun 9 is located inside the heating box 8; The frame 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com